Polymer composite material based on aromatic compound modified heat-conducting insulating composite powder and preparation of polymer composite material

An aromatic compound and composite powder technology, which is applied in heat exchange materials, chemical instruments and methods, etc., can solve problems such as troublesome processes, and achieve the effects of easy formation, simple and easy modification methods, and easy heat conduction network paths.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

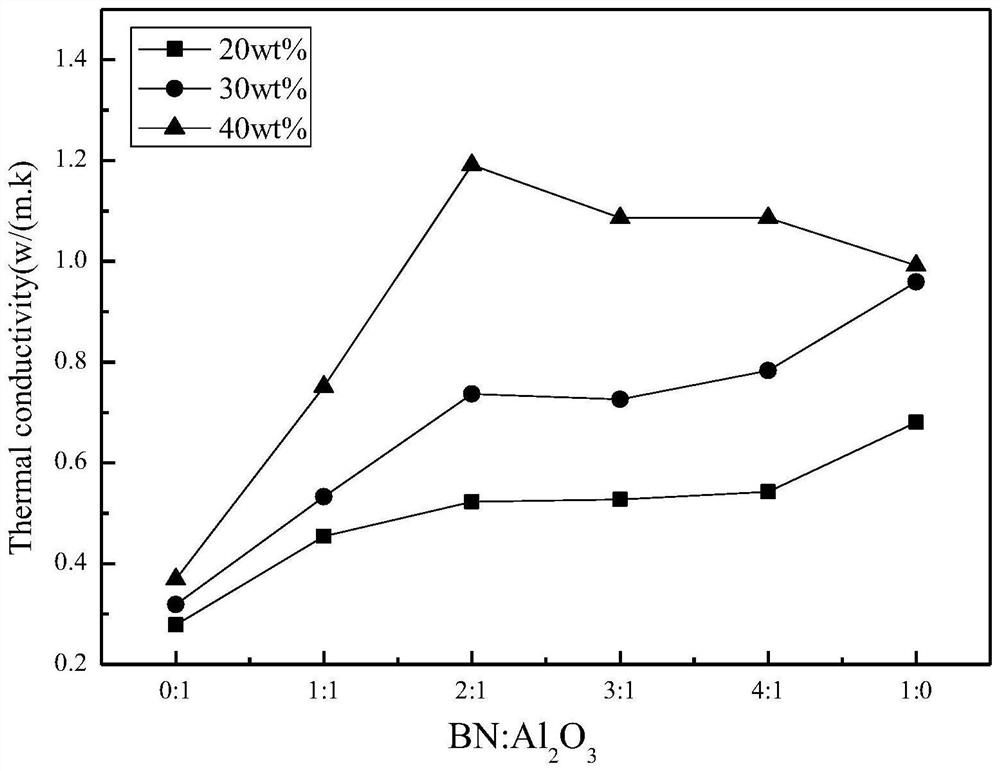

[0056] (1) 10 g of thermally conductive inorganic particles h-BN powder and Al 2 O 3 The powder was dispersed in 400 ml of deionized water, and ultrasonically dispersed for 2 hours to obtain dispersions A and B;

[0057] (2) 1g of dopamine hydrochloride was dispersed in 100ml of deionized water respectively, and ultrasonically dispersed for 30min to obtain dispersions C and D;

[0058] (3) A dispersion liquid and C dispersion liquid are mixed respectively, B dispersion liquid and D dispersion liquid are mixed, while stirring, drip Tris-HCl buffer solution and ammoniacal liquor, adjust pH to be 8.5, obtain E and F dispersion liquid;

[0059] (4) stirring E and F dispersions respectively at 600r / min at room temperature for 24 hours;

[0060] (5) Stand E and F dispersions, centrifuge at 5000r / min for 10min respectively, take the precipitate and wash it with clean water for 3-5 times, and then put it in an 80°C oven to dry for 12h (of course, other drying temperatures and drying...

Embodiment 2

[0066] (1) 10 g of thermally conductive inorganic particles h-BN powder and Al 2 O 3 The powder was dispersed in 400 ml of deionized water, and ultrasonically dispersed for 2 hours to obtain dispersions A and B;

[0067] (2) 1g of dopamine hydrochloride was dispersed in 100ml of deionized water respectively, and ultrasonically dispersed for 30min to obtain dispersions C and D;

[0068] (3) A dispersion liquid and C dispersion liquid are mixed respectively, B dispersion liquid and D dispersion liquid are mixed, while stirring, drip Tris-HCl buffer solution and ammoniacal liquor, adjust pH to be 8.5, obtain E and F dispersion liquid;

[0069] (4) stirring E and F dispersions respectively at 600r / min at room temperature for 24 hours;

[0070] (5) Stand E and F dispersions, centrifuge at 5000r / min for 10min respectively, take the precipitate and wash it with clean water for 3-5 times, and then put it in an 80°C oven to dry for 12h (of course, other drying temperatures and drying...

Embodiment 3

[0076] (1) 10 g of thermally conductive inorganic particles h-BN powder and Al 2 O 3 The powder was dispersed in 400 ml of deionized water, and ultrasonically dispersed for 2 hours to obtain dispersions A and B;

[0077] (2) 1g of dopamine hydrochloride was dispersed in 100ml of deionized water respectively, and ultrasonically dispersed for 30min to obtain dispersions C and D;

[0078] (3) A dispersion liquid and C dispersion liquid are mixed respectively, B dispersion liquid and D dispersion liquid are mixed, while stirring, drip Tris-HCl buffer solution and ammoniacal liquor, adjust pH to be 8.5, obtain E and F dispersion liquid;

[0079] (4) stirring E and F dispersions respectively at 600r / min at room temperature for 24 hours;

[0080](5) Stand E and F dispersions, centrifuge at 5000r / min for 10min respectively, take the precipitate and wash it with clean water for 3-5 times, and then put it in an 80°C oven to dry for 12h (of course, other drying temperatures and drying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap