High-performance ceramic simulating coating for multiple interfaces and preparation method of high-performance ceramic simulating coating

A kind of imitation porcelain paint, high-performance technology, applied in the direction of coating, can solve the problems of complex process, difficult to adhere, insufficient paint adhesion, etc., to achieve the effect of good stain resistance, good hiding power, and smooth interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

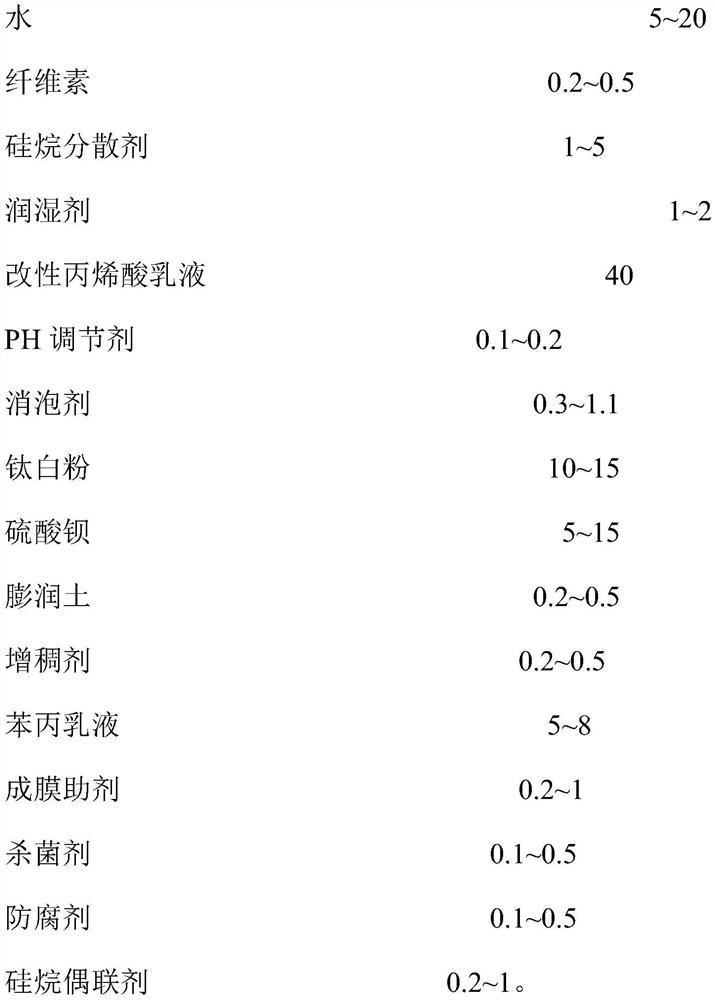

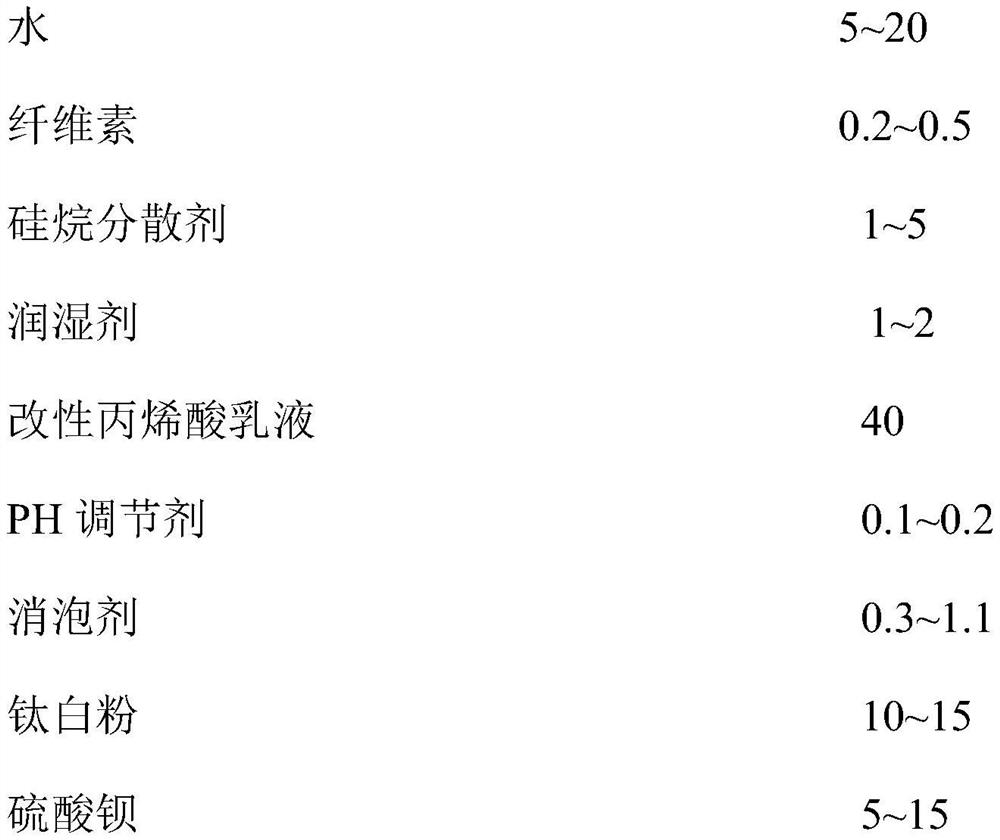

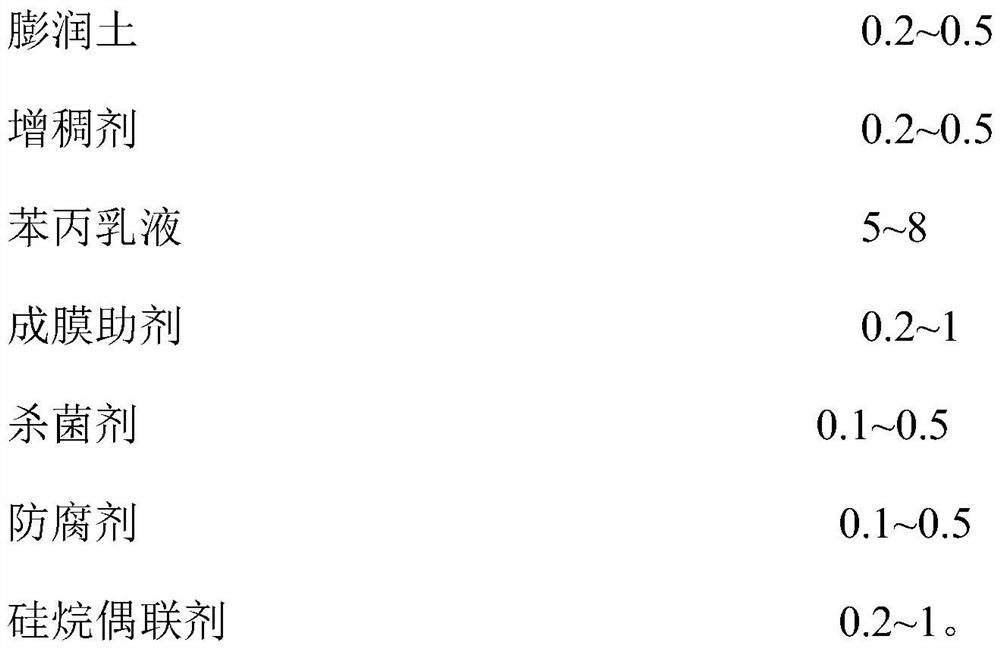

[0032] A high-performance porcelain-like coating for multiple interfaces is prepared from the following components:

[0033]

[0034] A preparation method of a high-performance imitation porcelain coating for multiple interfaces, comprising the steps of:

[0035] 1) Disperse water and cellulose uniformly, then add silane dispersant, wetting agent and pH regulator and stir well;

[0036] 2) Then continue to add 15 parts of modified acrylic emulsion, add 0.5 part of defoamer after stirring evenly, and continue to disperse;

[0037] 3) Then continue to add titanium dioxide, barium sulfate and bentonite, and stir evenly at a stirring speed of 1500 r / min;

[0038] 4) Then add styrene-acrylic emulsion, 25 parts of modified acrylic emulsion, film-forming aids, thickeners and remaining defoamer, stir evenly and no bubbles are generated, then add preservatives and bactericides, and finally add silane The coupling agent is stirred evenly to obtain the high-performance imitation por...

Embodiment 2

[0040]

[0041] A preparation method of a high-performance imitation porcelain coating for multiple interfaces, comprising the steps of:

[0042] 1) Disperse water and cellulose uniformly, then add silane dispersant, wetting agent and pH regulator and stir well;

[0043] 2) Then continue to add 15 parts of modified acrylic emulsion, add 0.3 part of defoamer after stirring evenly, and continue to disperse;

[0044] 3) Then continue to add titanium dioxide, barium sulfate and bentonite, and stir evenly at a stirring speed of 2000 r / min;

[0045] 4) Then add styrene-acrylic emulsion, 25 parts of modified acrylic emulsion, film-forming aids, thickeners and remaining defoamer, stir evenly and no bubbles are generated, then add preservatives and bactericides, and finally add silane The coupling agent is stirred evenly to obtain the high-performance imitation porcelain coating for multiple interfaces.

Embodiment 3

[0047]

[0048]

[0049] A preparation method of a high-performance imitation porcelain coating for multiple interfaces, comprising the steps of:

[0050] 1) Disperse water and cellulose uniformly, then add silane dispersant, wetting agent and pH regulator and stir well;

[0051] 2) Then continue to add 15 parts of modified acrylic emulsion, add 0.3 part of defoamer after stirring evenly, and continue to disperse;

[0052] 3) Then continue to add titanium dioxide, barium sulfate and bentonite, and stir evenly at a stirring speed of 1800 r / min;

[0053] 4) Then add styrene-acrylic emulsion, 25 parts of modified acrylic emulsion, film-forming aids, thickeners and remaining defoamer, stir evenly and no bubbles are generated, then add preservatives and bactericides, and finally add silane The coupling agent is stirred evenly to obtain the high-performance imitation porcelain coating for multiple interfaces.

[0054] The silane coupling agent in the above embodiment adopts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com