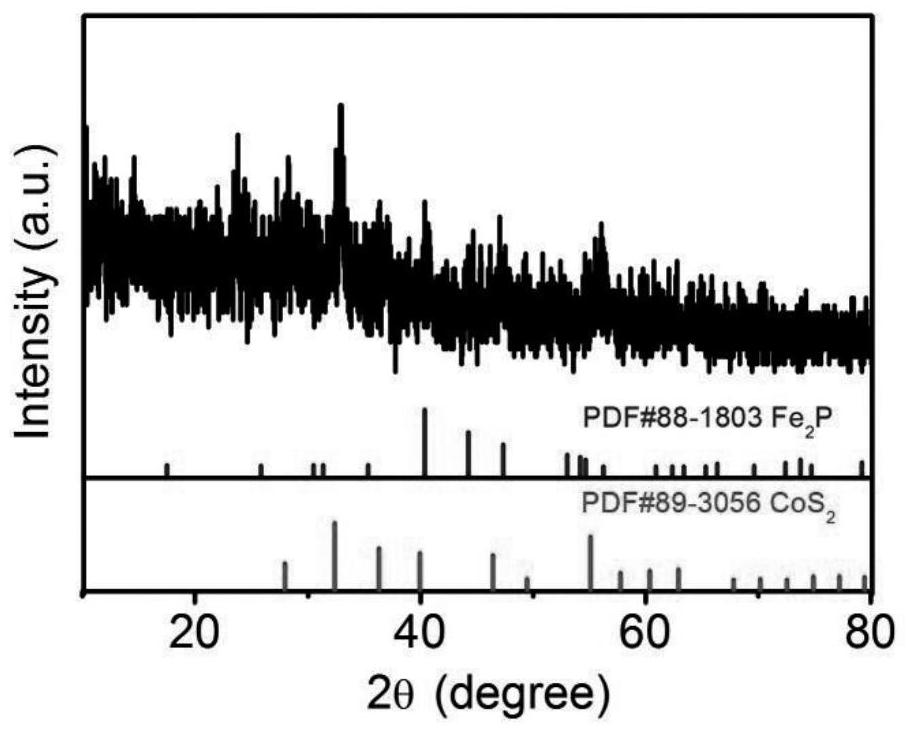

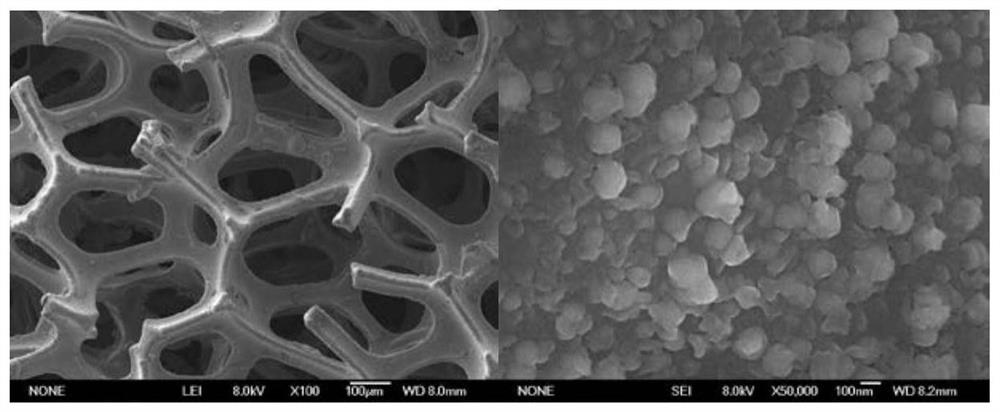

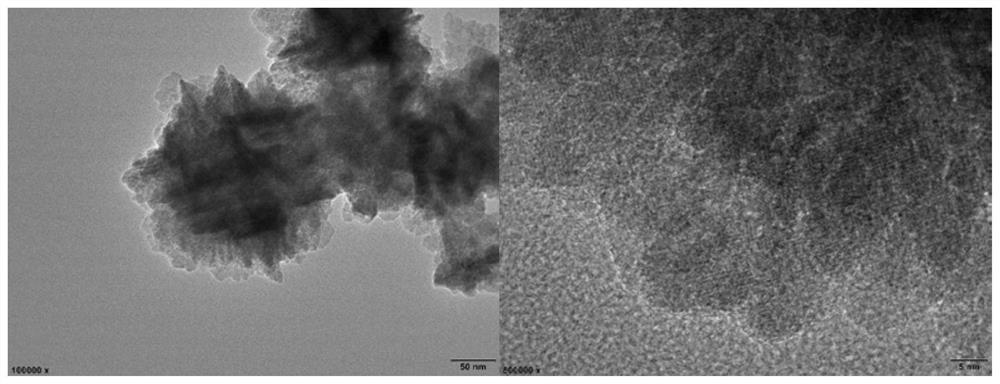

Preparation method of multi-element doped Fe2P/CoS2 tortoise-shell-shaped composite electrode material

A technology of composite electrodes and electrode materials, applied in electrodes, electrolysis components, electrolysis processes, etc., can solve the problems of limited active edge sites, cumbersome process of heterojunction catalysts, poor conductivity, etc., to improve catalytic activity and stability. , The effect of improving long-term working stability and improving interface charge transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) 10ml polyethylene glycol 200, 0.3g thiourea, and 0.2g hydroxyethylidene diphosphoric acid were heated and melted at 60°C to form a uniform liquid;

[0018] (2) 0.6g of ferric nitrate was added to the uniform liquid obtained in step (1), transferred to an autoclave, put in 1 piece of 1*1 cobalt foam, kept at 180°C for 8h, cooled, taken out, and deionized in turn N, O, S doped Fe was obtained by washing with water and absolute ethanol 2 P / N,O,P doped CoS 2 Composite electrode materials.

Embodiment 2

[0020] (1) 10ml polyethylene glycol 200, 0.6g thiourea, and 0.2g hydroxyethylidene diphosphoric acid were heated and melted at 60°C to form a uniform liquid;

[0021] (2) 1.2g of ferric nitrate was added to the uniform liquid obtained in step (1), transferred to an autoclave, put in 1 piece of 1*1 cobalt foam, kept at 180°C for 8h, cooled, taken out, and deionized in turn N, O, S doped Fe was obtained by washing with water and absolute ethanol 2 P / N,O,P doped CoS 2 Composite electrode materials.

Embodiment 3

[0023] (1) 10ml of polyethylene glycol 200, 0.3g of thiourea, and 0.4g of hydroxyethylidene diphosphoric acid were heated and melted at 60°C to form a uniform liquid;

[0024] (2) 0.6g of ferric nitrate was added to the uniform liquid obtained in step (1), transferred to an autoclave, put in 2 pieces of 1*1 cobalt foam, kept at 180°C for 8h, cooled, taken out, and deionized in turn N,O,C,S doped Fe was obtained by washing with water and absolute ethanol 2 P / N,O,C,P doped CoS 2 Composite electrode materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com