Preparation method of Fe (Se, Te) superconducting wire

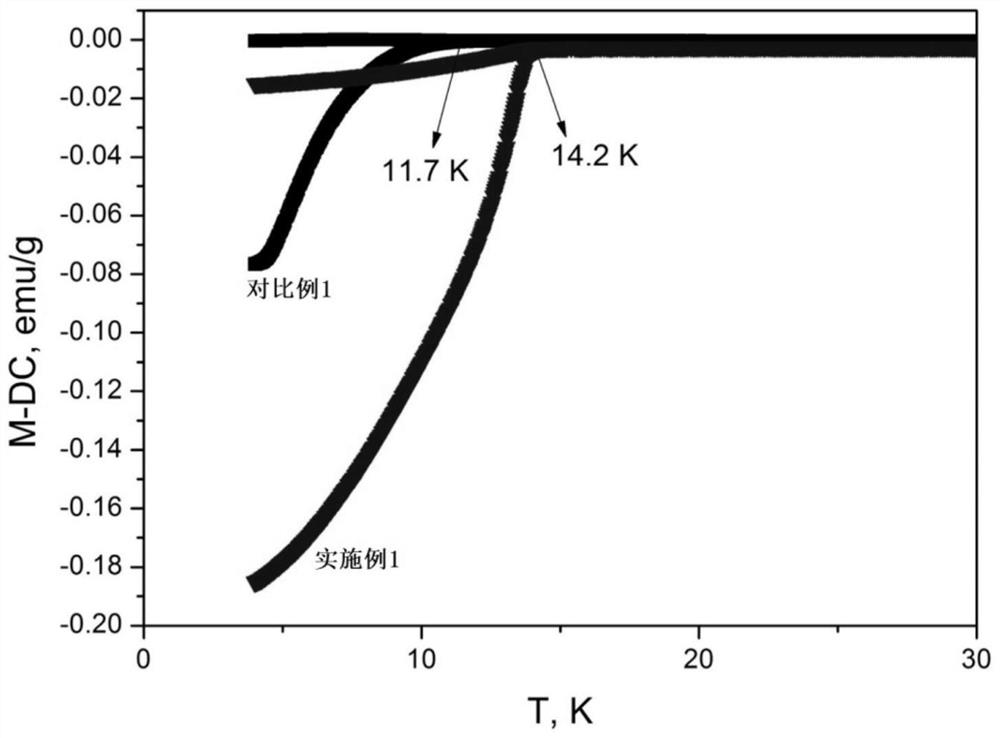

A technology of superconducting wire and mixed powder, which is applied in the direction of superconducting devices, cable/conductor manufacturing, superconducting/high-conducting conductors, etc. It can solve the problems of poor connectivity of grain boundaries of superconducting core wires and shorten the ball milling time , high grain boundary connectivity, simple and cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment includes the following steps:

[0032] Step 1, in a glove box full of inert gas, place the mixed powder in an agate mortar and grind for 30min; the mixed powder is composed of selenium powder and tellurium powder in a molar ratio of 1.0:1.0;

[0033] The mass purity of the selenium powder and the tellurium powder are both 99.99%;

[0034] Step 2, in a glove box filled with inert gas, put the mixed powder after grinding in step 1 into a tableting die and seal it, then take it out and place it on a tableting machine for pressing to obtain a Se-Te green body; The pressure of the pressing treatment is 10MPa, and the time is 10min;

[0035]Step 3: The Se-Te body obtained in step 2 is taken out from the tableting die and placed in a quartz tube, sealed with a oxyhydrogen flame, and then placed in a sintering furnace for sintering treatment, and cooled to room temperature to obtain SeTe block; the sintering treatment is carried out in an argon atmosphere, and...

Embodiment 2

[0049] This embodiment includes the following steps:

[0050] Step 1. In a glove box filled with inert gas, the mixed powder is placed in an agate mortar and ground for 120 min; the mixed powder is composed of selenium powder and tellurium powder in a molar ratio of 1.5:1.0;

[0051] The mass purity of the selenium powder and the tellurium powder are both 99.99%;

[0052] Step 2, in a glove box filled with inert gas, put the mixed powder after grinding in step 1 into a tableting die and seal it, then take it out and place it on a tableting machine for pressing to obtain a Se-Te green body; The pressure of the pressing treatment is 18MPa, and the time is 10min;

[0053] Step 3: The Se-Te body obtained in step 2 is taken out from the tableting die and placed in a quartz tube, sealed with a oxyhydrogen flame, and then placed in a sintering furnace for sintering treatment, and cooled to room temperature to obtain SeTe block; the sintering treatment is carried out in an argon atm...

Embodiment 3

[0062] This embodiment includes the following steps:

[0063] Step 1, in a glove box filled with inert gas, place the mixed powder in an agate mortar and grind for 60min; the mixed powder is composed of selenium powder and tellurium powder in a molar ratio of 1.2:1.0;

[0064] The mass purity of the selenium powder and the tellurium powder are both 99.99%;

[0065] Step 2, in a glove box filled with inert gas, put the mixed powder after grinding in step 1 into a tableting die and seal it, then take it out and place it on a tableting machine for pressing to obtain a Se-Te green body; The pressure of the pressing treatment is 5MPa, and the time is 10min;

[0066] Step 3: The Se-Te body obtained in step 2 is taken out from the tableting die and placed in a quartz tube, sealed with a oxyhydrogen flame, and then placed in a sintering furnace for sintering treatment, and cooled to room temperature to obtain SeTe block; the sintering treatment is carried out in an argon atmosphere,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| superconducting critical temperature | aaaaa | aaaaa |

| superconducting critical temperature | aaaaa | aaaaa |

| critical temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com