Preparation method of single fuel cell

A fuel cell and single cell technology, applied in fuel cell parts, fuel cells, circuits, etc., can solve the problems of poor adhesion of the sealant line, uneven size of the glue line, easy sealing failure, etc., and achieve pattern design. Flexible, adaptable glue, anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

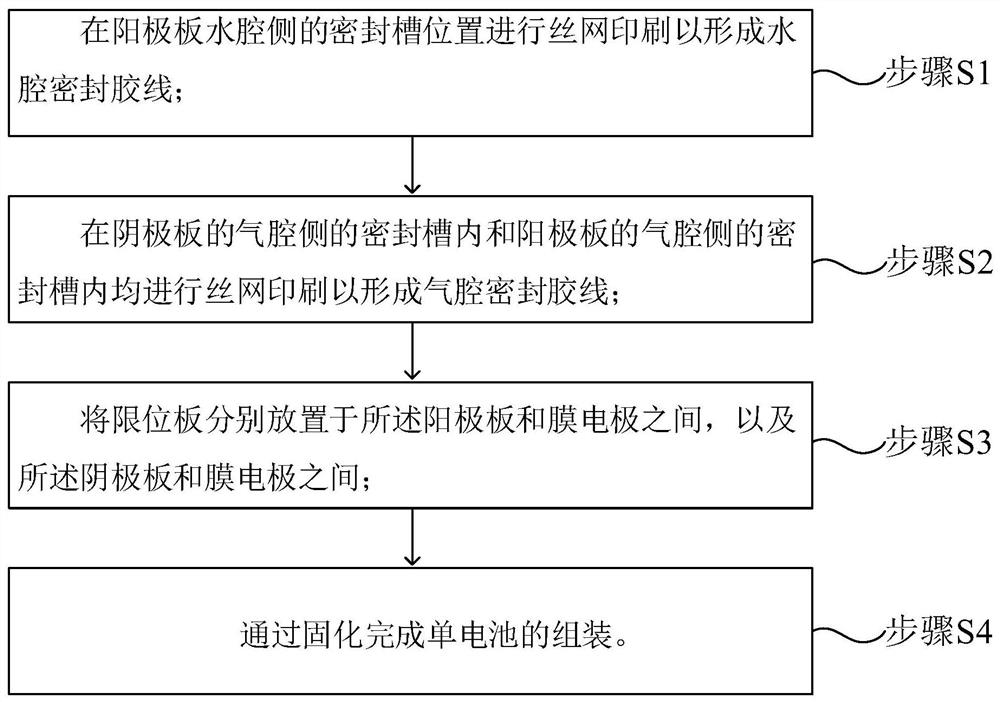

[0024] like figure 1 As shown, the preparation method includes:

[0025] Step S1, screen printing is performed on the sealing groove position on the water cavity side of the anode plate to form the water cavity sealant line; specifically, the water cavity sealing adopts the screen printing method to avoid corrosion of the metal plate during the welding process.

[0026] In specific use, the sealing performance and bonding performance of silicone rubber are fully utilized. That is, two-component or one-component liquid silicone rubber with a viscosity of 5-15*104mPa.S@25℃ is selected, and screen printing is performed on the sealing groove on the water cavity side of the anode plate. In other embodiments, the material of screen printing may not be limited.

[0027] Step S2, screen printing is performed in the sealing groove on the air cavity side of the cathode plate and in the sealing groove on the air cavity side of the anode plate to form the air cavity sealant line; In th...

Embodiment 1

[0051] Select two-component liquid silicone rubber WACKER Silica Gel with a viscosity of 5*104mPa.S@25℃, screen-print at the sealing groove on the water cavity side of the anode plate, heat and cure at 150℃ for 5min to form a water cavity seal glue line.

[0052] A steel mesh plate with a mesh number of 200 meshes, a wire diameter of 150 μm and a film thickness of 100 μm was selected and placed on the screen printing machine tooling.

[0053] Wipe the surface of the sealing groove on the air cavity side of the anode plate with alcohol, put it in the tooling to fix it, and align the air cavity sealing platform pattern with the stencil pattern.

[0054] Choose WACKER 624, a two-component liquid silicone rubber with a viscosity of 5*104mPa.S@25℃. After mixing the glue completely, put it in a vacuum defoaming box to defoaming, and place it above the screen pattern.

[0055] Choose a polyurethane scraper with a hardness of 65A. The squeegee compresses the screen at a speed of 80 ...

Embodiment 2

[0062] Momentive silica gel, a two-component liquid silicone rubber with a viscosity of 7*104mPa.S@25℃, was selected for screen printing at the sealing groove on the water cavity side of the anode plate, and heated and cured at 150℃ for 3 minutes to form a water cavity seal. glue line.

[0063] A steel mesh plate with a mesh number of 150 mesh, a wire diameter of 80 μm and a film thickness of 80 μm was selected and placed on the screen printing machine tooling.

[0064] Wipe the surface of the sealing groove on the air cavity side of the anode plate with alcohol, put it in the tooling to fix it, and align the air cavity sealing platform pattern with the stencil pattern.

[0065] Dow Corning single-component silicone rubber with a viscosity of 9*104mPa.S@25℃ was selected and placed above the stencil pattern.

[0066] Choose a polyurethane scraper with a hardness of 45A. The squeegee compresses the screen at a speed of 100 mm / sec, at an angle of 13 degrees, and passes the sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com