Hard mask repairing patch capable of being sewn and pasted as well as preparation method and application of hard mask repairing patch

A technology of patch and dura mater, applied in the field of suturable and affixable dura mater repair patch and its preparation, can solve the problems of poor adhesion between biofilm and tissue, unfavorable defect repair, single use method, etc., and achieve excellent The effect of suture performance, smooth surface, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

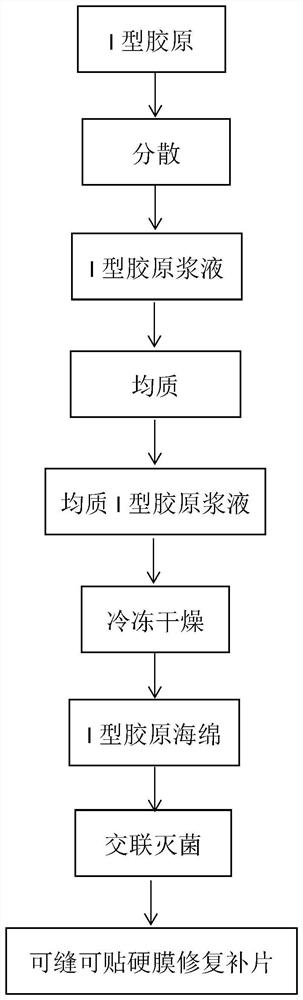

[0058] The preparation method of the above-mentioned sewable and stickable dura mater repair patch, such as figure 1 shown, including the following steps:

[0059] (1) Dispersion; disperse type I collagen in an acidic medium to prepare a type I collagen slurry with a concentration of 0.8-2%; wherein, the type I collagen is type I collagen with triple helix structure; the acidic medium The pH is 2-5; the acidic medium is selected from acetic acid and hydrochloric acid.

[0060] (2) Homogenization: a homogenizer connected to a vacuum system is used to homogenize the type I collagen slurry and remove air bubbles to obtain a homogeneous type I collagen slurry; the homogenization frequency of the homogenizer is 20-60 Hz , the number of cycles is 5-20 times, the time of homogenization is 5min-1h, and the temperature of homogenization is 0-20°C.

[0061] (3) Freeze-drying: First, pour the homogenous type I collagen slurry into the mold to ensure that the amount of the homogenous ty...

Embodiment 1-3

[0067] Embodiments 1-3 respectively provide a preparation method of a sewable and stickable dura mater repair patch.

[0068] The difference between the above embodiments is: in the dispersion step, the concentration of the type I collagen slurry is specifically shown in Table 1.

[0069] The preparation method of the sewable and stickable dura mater repair patch provided by embodiment 2 specifically comprises the following steps:

[0070] (1) Dispersion: Disperse the triple-helix type I collagen in a 0.05M acetic acid solution to prepare a type I collagen slurry with a concentration of 1.5%.

[0071] (2) Homogenization: a homogenizer connected with a vacuum system is used to homogenize the type I collagen slurry and remove air bubbles to obtain a homogeneous type I collagen slurry; the homogenization frequency of the homogenizer is 40 Hz, and the cycle The number of times is 5, the time of homogenization is 10min, and the temperature of homogenization is 5°C.

[0072] (3) F...

Embodiment 4-7

[0077] Embodiments 4-7 respectively provide a preparation method of a seamable and stickable dura mater repair patch.

[0078] The difference between the above embodiment and Embodiment 2 is that: in the homogenization step, the homogenization frequency of the homogenizer is specifically shown in Table 2.

[0079] The homogenization frequency of the homogenizer in the preparation method provided in Table 2 Example 2 and Example 4-7

[0080] Example Homogeneous frequency (Hz) 2 40 4 10 5 20 6 60 7 70

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com