Water-based nano high-temperature-resistant thermal insulation material and preparation method thereof

A technology of thermal insulation and high temperature resistance, which is applied in the field of water-based nano-temperature-resistant thermal insulation materials and preparation, can solve the problems of other raw material performance changes, and achieve the effects of reducing heat gain, tight connection, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

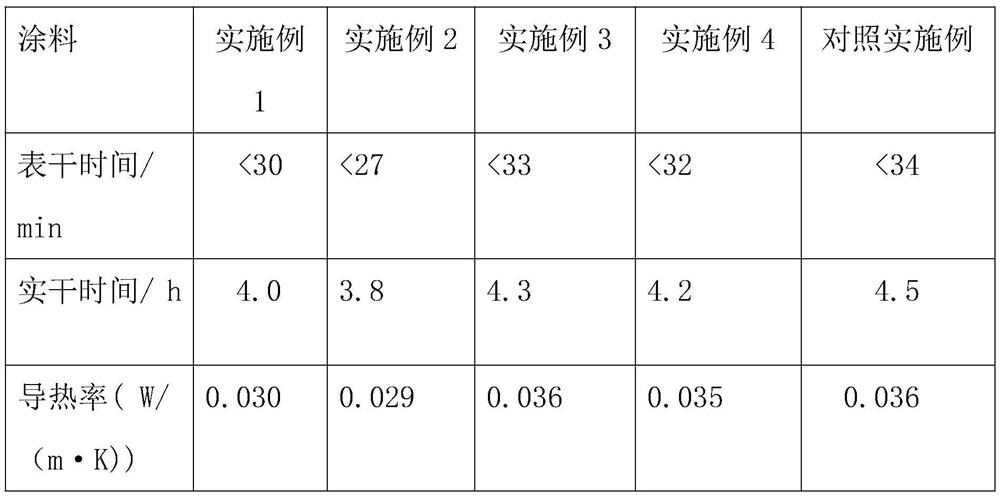

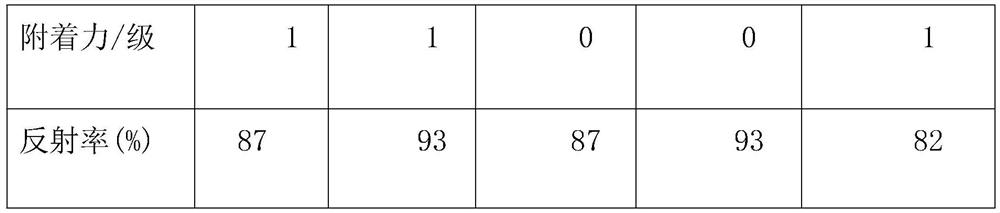

Examples

Embodiment 1

[0030] The specific steps of the preparation method are as follows:

[0031] (1), add 26% of water, 4% of infrared reflective pigment, and 0.8% of pigment dispersant into the dispersing tank and stir evenly, the stirring speed is 120r / min, and the stirring time is 8min to obtain mixture A;

[0032] (2), slowly add 19% of titanium-plated nano-ceramic hollow microbeads, 0.6% of emulsifier, 0.8% of thickener, 0.5% of defoamer, 0.3% of leveling agent, and 8% of emulsion to the mixture A of step 1 at low speed Stir evenly, the stirring speed is 45r / min, and the stirring time is 50min to obtain mixture B;

[0033] (3), adding 26% of silica aerogel and 16% of water-based resin to the mixture B obtained in step 2 and continued stirring for 27 min at a rotating speed of 45r / min to obtain the water-based nanometer high-temperature-resistant thermal insulation material.

Embodiment 2

[0035] The specific steps of the preparation method are as follows:

[0036] (1), adding 18% water, 10% infrared reflective pigment, and 0.8% pigment dispersant into the dispersing tank and stirring evenly, the stirring speed is 120r / min, and the stirring time is 8min to obtain mixture A;

[0037] (2), slowly add 19% of titanium-plated nano-ceramic hollow microbeads, 0.6% of emulsifier, 0.8% of thickener, 0.5% of defoamer, 0.3% of leveling agent, and 8% of emulsion to the mixture A of step 1 at low speed Stir evenly, the stirring speed is 45r / min, and the stirring time is 50min to obtain mixture B;

[0038] (3), adding 26% of silica aerogel and 16% of water-based resin to the mixture B obtained in step 2 and continued stirring for 27 min at a rotating speed of 45 r / min to obtain the water-based nanometer high-temperature-resistant thermal insulation material.

Embodiment 3

[0040] The specific steps of the preparation method are as follows:

[0041] (1), adding 38% water, 4% infrared reflective pigment, and 0.8% pigment dispersant into the dispersing tank and stirring evenly, the stirring speed is 120r / min, and the stirring time is 8min to obtain mixture A;

[0042] (2), slowly add 19% of titanium-plated nano-ceramic hollow microbeads, 0.6% of emulsifier, 0.8% of thickener, 0.5% of defoamer, 0.3% of leveling agent, and 10% of emulsion to the mixture A of step 1 at low speed Stir evenly, the stirring speed is 45r / min, and the stirring time is 50min to obtain mixture B;

[0043](3), adding 4% of silica aerogel and 22% of water-based resin to the mixture B obtained in step 2 and continued to stir for 27 min at a rotating speed of 45r / min to obtain the water-based nano-temperature-resistant thermal insulation material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com