Design method for life robustness of hot component of gas turbine

A technology of gas turbine and design method, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve the problem of low life robustness of gas turbine thermal components, achieve low cycle fatigue life of precise thermal components, reduce maintenance costs, prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

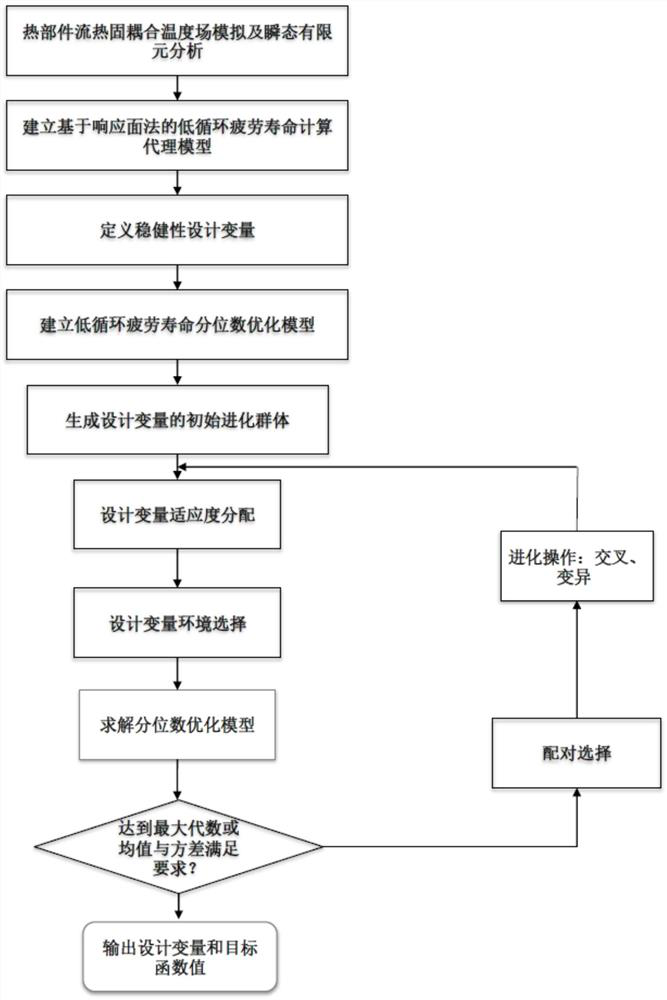

[0054] according to Figure 1-Figure 3 The design method for the life robustness of gas turbine thermal components is shown, and the low-cycle fatigue life of a ground gas turbine turbine blade is robustly designed. The specific steps include:

[0055] Step S1: Perform CFD calculation on the flow field and solid temperature field of the turbine blade to obtain the temperature field distribution of the turbine blade. At the same time, the transient finite element analysis method is used to analyze the solid domain of the turbine blade, and the air film hole edge of the blade body is determined by the calculation result. is the check point, and then the cyclic stress-strain curve of the air film hole edge of the blade body is obtained;

[0056] Specifically, this region has a high stress level due to a large temperature gradient.

[0057] Step S2: Obtain the strain amplitude of the turbine blade from the start-up to the shutdown process of the check point through the cyclic str...

Embodiment 2

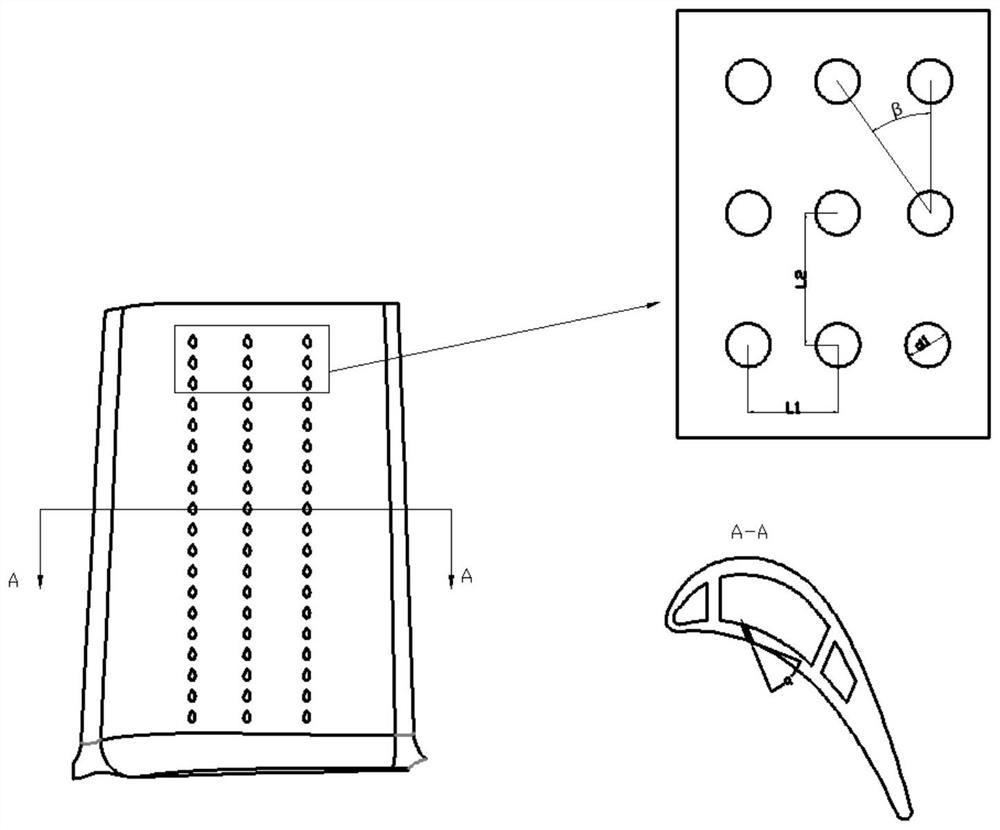

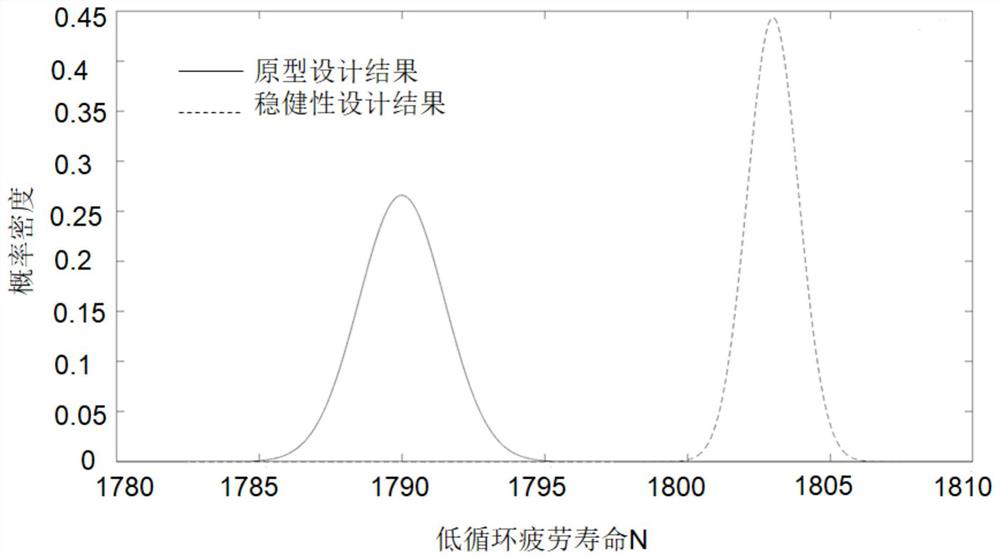

[0090] according to figure 1 , Figure 4 and Figure 5 The design method for the life robustness of gas turbine thermal components is shown, and the low cycle fatigue life of a ground gas turbine flame tube is robustly designed. The specific steps include:

[0091] Step S1: use the flow-heat-solid coupling analysis method to perform CFD calculation on the flow field and solid temperature field of the flame tube to obtain the temperature field distribution of the flame tube, and at the same time use the transient finite element analysis method to analyze the solid domain of the combustion chamber flame tube , the cyclic stress-strain curve of the gas film hole edge of the flame cylinder during the start-up to shutdown process of the gas turbine is obtained through the calculation results;

[0092] Specifically, this region has a high stress level due to a large temperature gradient.

[0093] Step S2: Obtain the strain amplitude of the flame tube from the start-up to the shut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com