Battery diaphragm with irregularly-shaped particle coating and preparation method of battery diaphragm

A battery separator, irregular technology, applied in the field of battery separator with irregular particle coating and its preparation, can solve the problem of poor heat resistance of polyolefin separator, achieve improved heat resistance, low thermal shrinkage, and guarantee safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

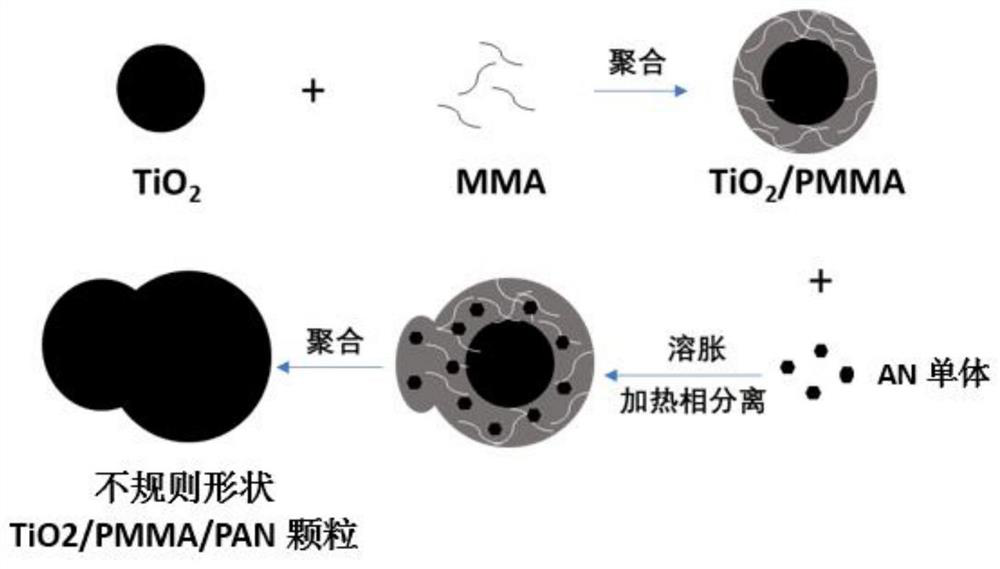

[0024] A battery separator with a coating of irregular-shaped particles, comprising a PP base film and a coating covering the surface of the PP base film, the irregular-shaped particles are uniformly distributed in the coating, and the structure of the irregular-shaped particles is including TiO 2 Spherical particles coated with PMMA (hereinafter abbreviated as TiO) 2 / PMMA), and a PAN polymer layer polymerized after partially swelling the surface-coated PMMA, the irregular-shaped particles are abbreviated as TiO 2 / PMMA / PAN.

[0025] The preparation of irregular-shaped particles includes the following steps: 2 / PMMA spherical particles dispersed in water to form a dispersion with a solid content of 8 wt%, N 2 After bubbling for 30min to deoxygenate, add AN, swell at room temperature, then heat up to 65°C, add KPS initiator to carry out polymerization reaction for 2h, the raw material of polymerization reaction is TiO 2 The mass ratio of / PMMA spherical particles, AN, and ...

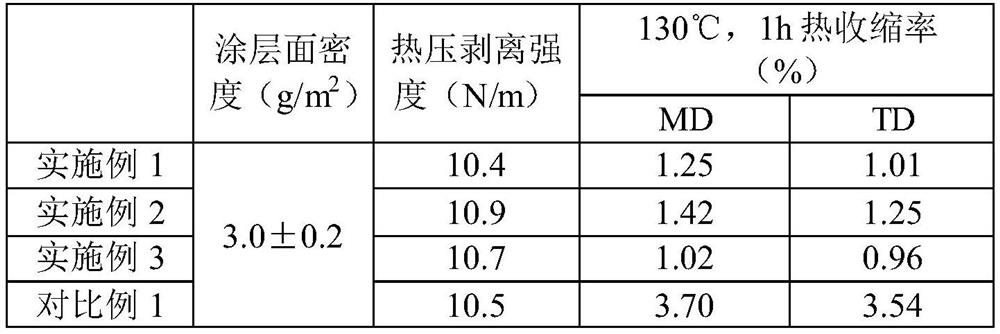

Embodiment 2

[0030] The structure and preparation of the battery separator with irregular-shaped particle coating in this example is the same as that in Example 1, the difference is that in the preparation of the battery separator with irregular-shaped particle coating, the slurry is prepared according to the mass percentage of 100 %, the TiO 2 / PMMA / PAN irregular-shaped particles accounted for 25%, aqueous thickener accounted for 30%, aqueous binder 4%, aqueous wetting agent 0.2%, and the balance was water.

Embodiment 3

[0032] The structure and preparation of the battery separator with irregular-shaped particle coating in this example is the same as that in Example 1, the difference is that in the preparation of the battery separator with irregular-shaped particle coating, the slurry is prepared according to the mass percentage of 100 %, the TiO 2 / PMMA / PAN irregular-shaped particles accounted for 25%, aqueous thickener accounted for 35%, aqueous binder 8%, aqueous wetting agent 0.3%, and the balance was water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com