Microwave coupling plasma and high-temperature flame fusion excitation source

A technology for coupling plasma and excitation source, which is applied in the field of analytical instruments, can solve the problems of lack of elastic collision and low temperature of plasma gas, and achieve the effects of high atomization efficiency, high gas temperature and strong excitation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

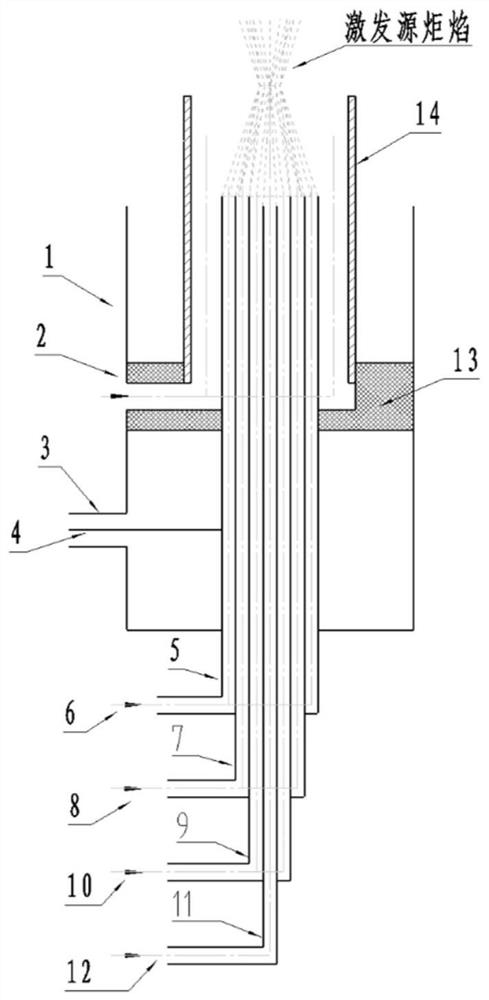

[0030] like figure 1 As shown in the figure, a microwave energy transmission part is an antenna-type microwave-coupled plasma and high-temperature flame fusion excitation source, including an outer conductor 1, a shielding gas inlet 2, a microwave input port 3, a microwave antenna 4, an inner conductor 5, an outer gas Inlet 6 , middle tube 7 , middle layer gas inlet 8 , inner tube 9 , inner layer gas inlet 10 , sample tube 11 , sample aerosol inlet 12 , guide ring 13 and guide tube 14 .

[0031] The microwave energy transmission part includes a microwave input port 3 and a microwave antenna 4 . Install L16-KF or L29-KF microwave connectors at microwave input port 3. One end of the microwave connector is connected to the microwave source, and the other end is connected to the microwave antenna 4 . The microwave antenna 4 is located at a distance λ / 4 from the bottom surface of the resonant cavity. An electrical connection is maintained between the microwave antenna 4 and the ...

Embodiment 2

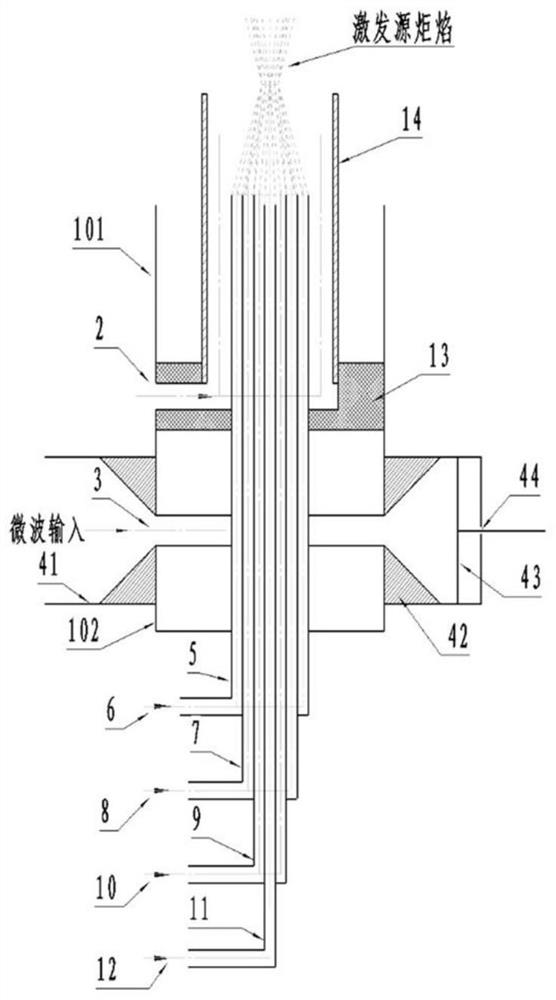

[0050] see figure 2 A microwave energy transmission part is a microwave coupling plasma and high temperature flame fusion excitation source in a waveguide mode, which is composed of a microwave energy transmission part and a microwave coaxial resonant cavity part.

[0051] The microwave energy transmission part includes a microwave input port 3 , a standard waveguide 41 , a waveguide-coaxial conversion cone 42 , a short-circuit piston 43 and an adjustment rod 44 . The microwave input port 3 is constituted by a gap formed between two waveguide-coaxial conversion cones 42 . The first port of the standard waveguide 41 is connected to the microwave generating system, the coaxial resonator outer conductor 1 is vertically installed on the upper outer wall in the length direction between the first port and the second port of the standard waveguide 41, and the lower inner wall in the length direction of the standard waveguide 41 is installed vertically. The waveguide-coaxial convers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com