Method for precipitating polymer

A polymer and copolymer technology, applied in the direction of amide/imide polymer adhesives, adhesive types, recycling technology, etc., can solve problems such as safety hazards, high energy consumption, and large energy costs, and achieve the elimination of Contamination, the effect of shortening the time spent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

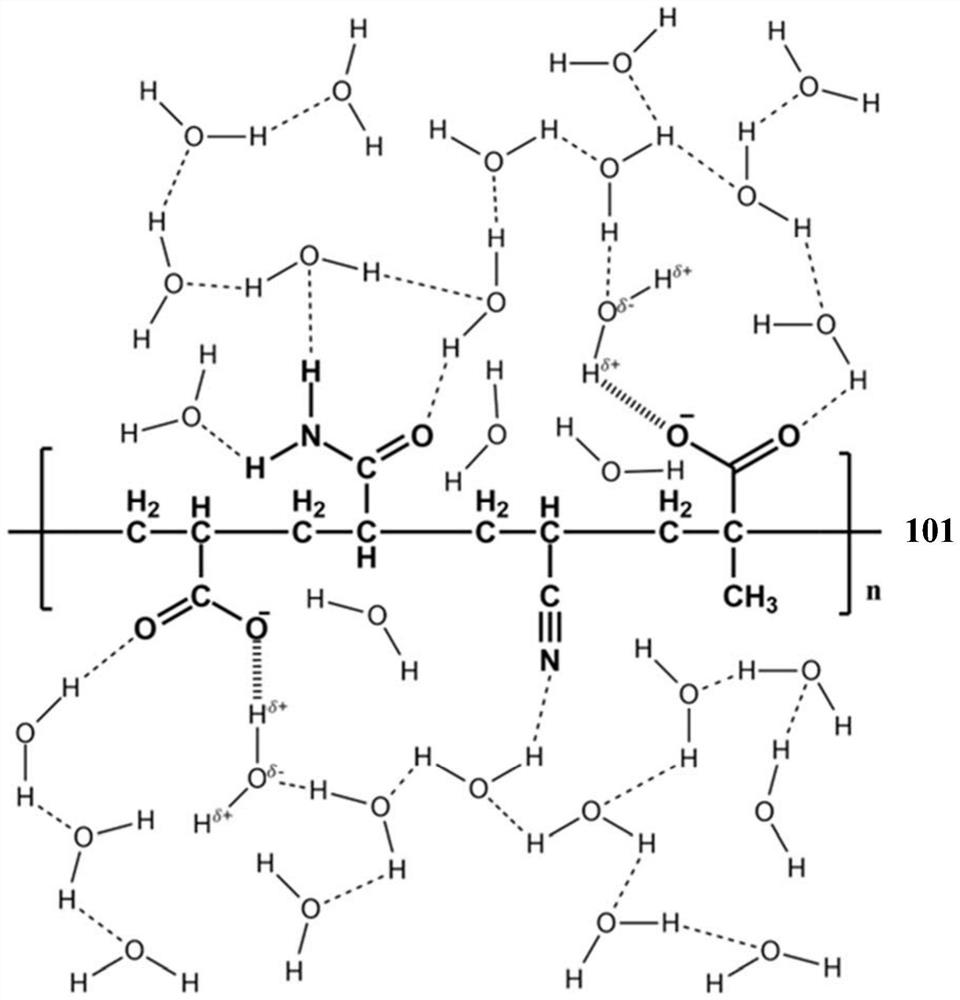

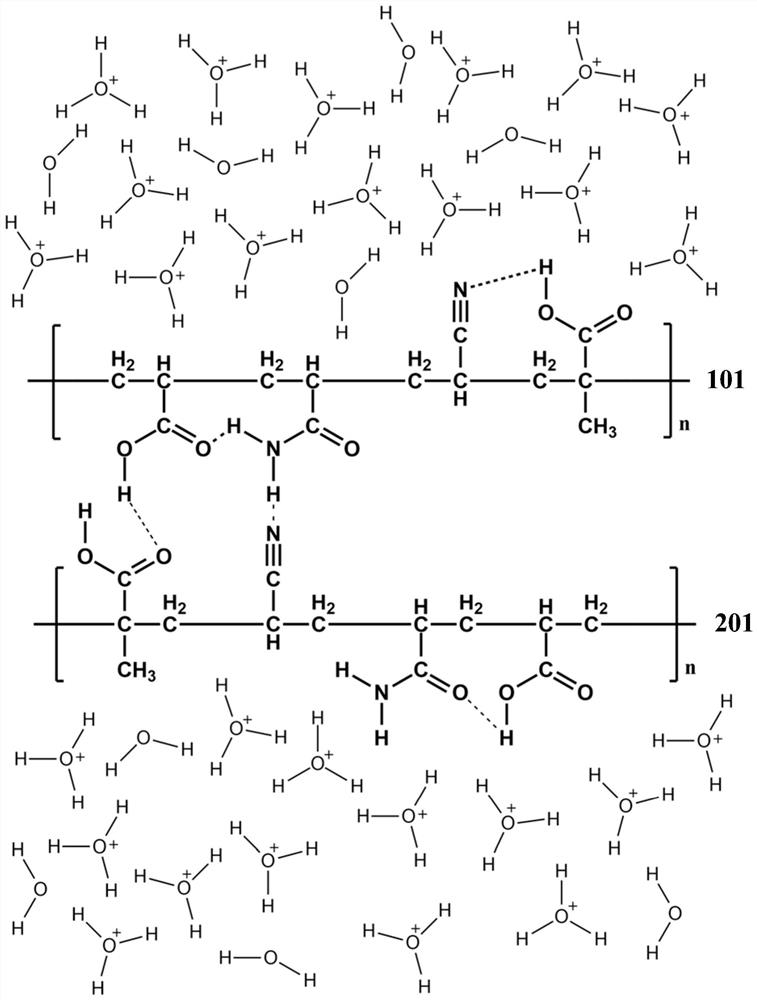

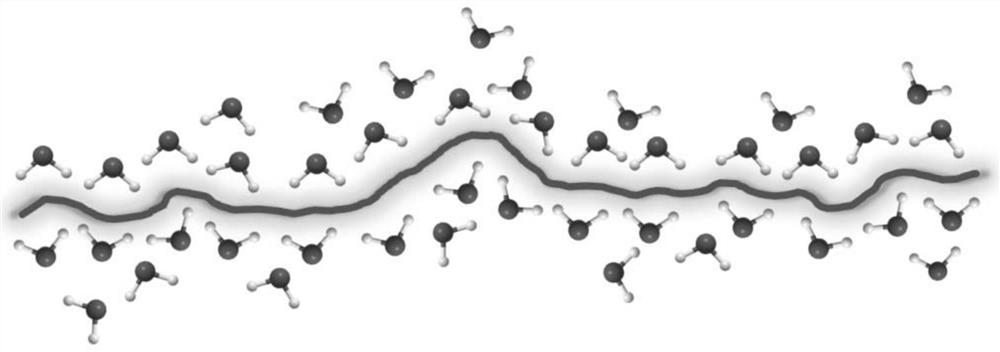

Method used

Image

Examples

Embodiment 1

[0335] Preparation of the first suspension

[0336] A) Preparation of polymers

[0337] 16 g of sodium hydroxide (NaOH) was added to a round bottom flask containing 380 g of distilled water. The combination of ingredients was stirred at 80 rpm for 30 minutes to obtain the first mixture.

[0338] 36.04 g of acrylic acid (AA) was added to the first mixture. The combination of raw materials was further stirred at 80 rpm for 30 minutes to obtain a second mixture.

[0339] 19.04 g of acrylamide (AM) was dissolved in 10 g of deionized water to form an AM solution. Then, 29.04 g of AM solution was added to the second mixture. The combination of raw materials was further heated to 55°C and stirred at 80 rpm for 45 minutes to obtain a third mixture.

[0340] 12.92 g of acrylonitrile (AN) was added to the third mixture. The combination of raw materials was further stirred at 80 rpm for 10 minutes to obtain a fourth mixture.

[0341] Further, 0.015g of water-soluble free radical i...

Embodiment 2

[0350] Preparation of the first suspension of Example 2

[0351] The preparation of the first suspension was carried out in the same manner as in Example 1, except that 5.56 g of polymer was added to 45.04 g of distilled water and the mixture was stirred at 80 rpm for 10 minutes to obtain 50.60 g of the first suspension .

[0352] Recovery of the polymer of Example 2

[0353] Recovery of the polymer was carried out in the same manner as in Example 1, except that a 1 M sulfuric acid solution was added to the first suspension to form a second suspension having a pH of 2.96.

Embodiment 3

[0354] Preparation of the first suspension of Example 3

[0355] The preparation of the first suspension was carried out in the same manner as in Example 1, except that 5.56 g of polymer was added to 44.52 g of distilled water and the mixture was stirred at 80 rpm for 10 minutes to obtain 50.08 g of the first suspension .

[0356] Recovery of the polymer of Example 3

[0357] Recovery of the polymer was carried out in the same manner as in Example 1, except that a 1 M sulfuric acid solution was added to the first suspension to form a second suspension having a pH of 2.07.

[0358] The recovery of the polymer of Example 3 was repeated by stirring the second suspension at 200 rpm for 60 minutes and 120 minutes, respectively, at 25°C. The second suspension stirred for 60 minutes gave a polymer recovery of 99.42%, while the second suspension stirred for 120 minutes gave a polymer recovery of 99.43%. There was no indication that polymer recovery increased significantly with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com