Antimicrobial dressing capable of being dissolved as required and preparation method thereof

A solution and surface modification technology, applied in medical science, bandages, etc., can solve problems such as poor biocompatibility, lack of antibacterial properties, and increased wound size, achieve excellent physical, chemical and biological properties, avoid secondary damage, The effect of good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of above-mentioned antibacterial dressing, comprises the steps:

[0036] 1) Add chitosan to a solution containing acetic acid and water, reflux at 40°C for 0.5-2h, add polyethylene glycol diacrylate, continue refluxing at 40°C for 12-48h, wash with water and alcohol, A highly transparent pale yellow prepolymer solution is obtained; the mass ratio of chitosan, acetic acid, polyethylene glycol diacrylate and water is 0.5-2:0.5-2:10-30:100.

[0037] 2) Weigh the surface-modified zinc oxide powder, and the particle size of the zinc oxide powder is 30-100 nm. Prepare a zinc oxide suspension with a mass fraction of 20%, and drop the suspension into the prepolymer solution obtained in step 1) to obtain a semi-solid gel product;

[0038] 3) placing the obtained semi-solid gel-like product in a dilute acetic acid solution, and the semi-solid gel-like product is dissolved within 1-2 minutes, and has good dissolving performance on demand.

[0039] Specific...

Embodiment 1

[0041] 1) Add 1 part of chitosan to a solution containing 1 part of acetic acid and 100 parts of water, reflux at 40 °C for 1 hour, add 20 parts of polyethylene glycol diacrylate, continue to reflux at 40 °C for 24 hours, wash with water and alcohol , a highly transparent pale yellow prepolymer solution was obtained.

[0042] 2) Weigh the surface-modified zinc oxide powder with a particle size of 30 nm, prepare a zinc oxide suspension with a mass fraction of 20%, drop the suspension into the above solution, and wait for a few seconds to obtain a semi-solid gel product.

[0043] 3) The gelatinous product is placed in a dilute acetic acid solution, and the gel is dissolved within 1-2min, indicating that the product has good solubility on demand.

Embodiment 2

[0045] Take the gel-like product prepared in Example 1 as a sample, and carry out relevant performance tests:

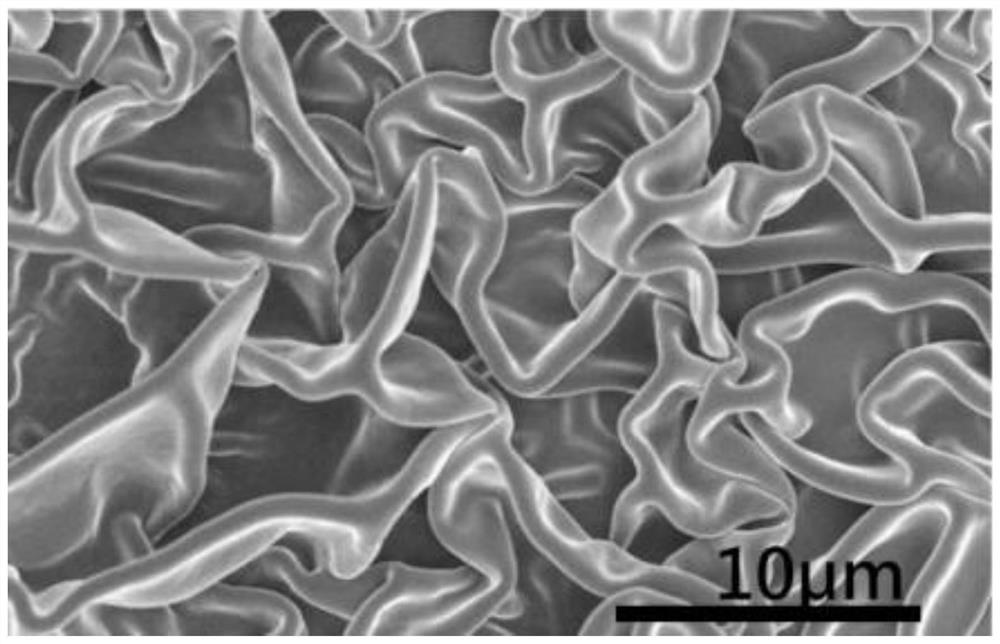

[0046] figure 1 It is a scanning electron microscope image of the product formed by the action of zinc oxide solution (particle size of 30nm) and prepolymer. It can be seen from the figure that the product presents a three-dimensional network porous structure with a pore size of about 2.0um. The developed porous structure gives the product excellent quality. It has good application prospects in the fields of dressings and the like.

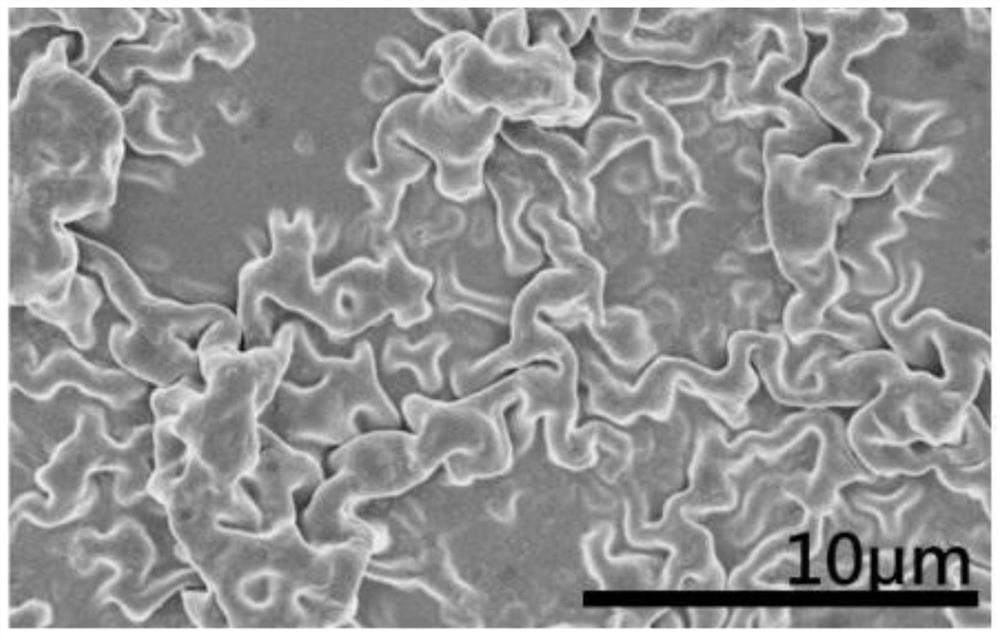

[0047] figure 2 The scanning electron microscope image of the product after adding a few drops of dilute acetic acid shows that the three-dimensional network structure has been destroyed, and most of the product has been degraded, indicating that the product has on-demand solubility.

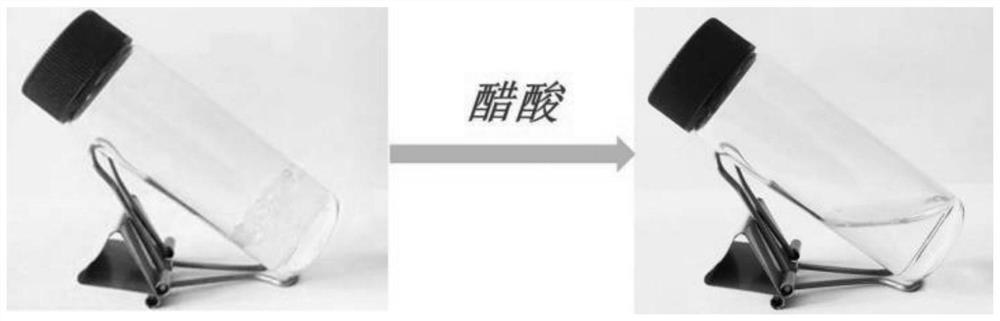

[0048] image 3 Optical photograph of degradation of a gel-like product.

[0049] Figure 4 For the antibacterial effect of the product on Escherichia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com