Turpentine-based vegetable oil and preparation method and application thereof

A technology of pine resin-based vegetable oil and vegetable oil, applied in the field of vegetable oil, can solve the problems of natural vegetable oil solubility, frost resistance, poor emulsification and dispersion, hindering use, etc., and achieve excellent physicochemical and biological properties, easy biodegradation, and wide source effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Put 190kg of ethanol and 10kg of sodium hydroxide into a high-shear emulsification and dispersion kettle, add 400kg of turpentine and 400kg of jatropha oil after mixing, start the high-shear emulsification and dispersion unit, raise the temperature to 60°C for 1 hour, and separate and remove impurities to obtain 880kg turpentine-based vegetable oil is sampled and detected, and the physicochemical properties of the product are shown in Table 2.

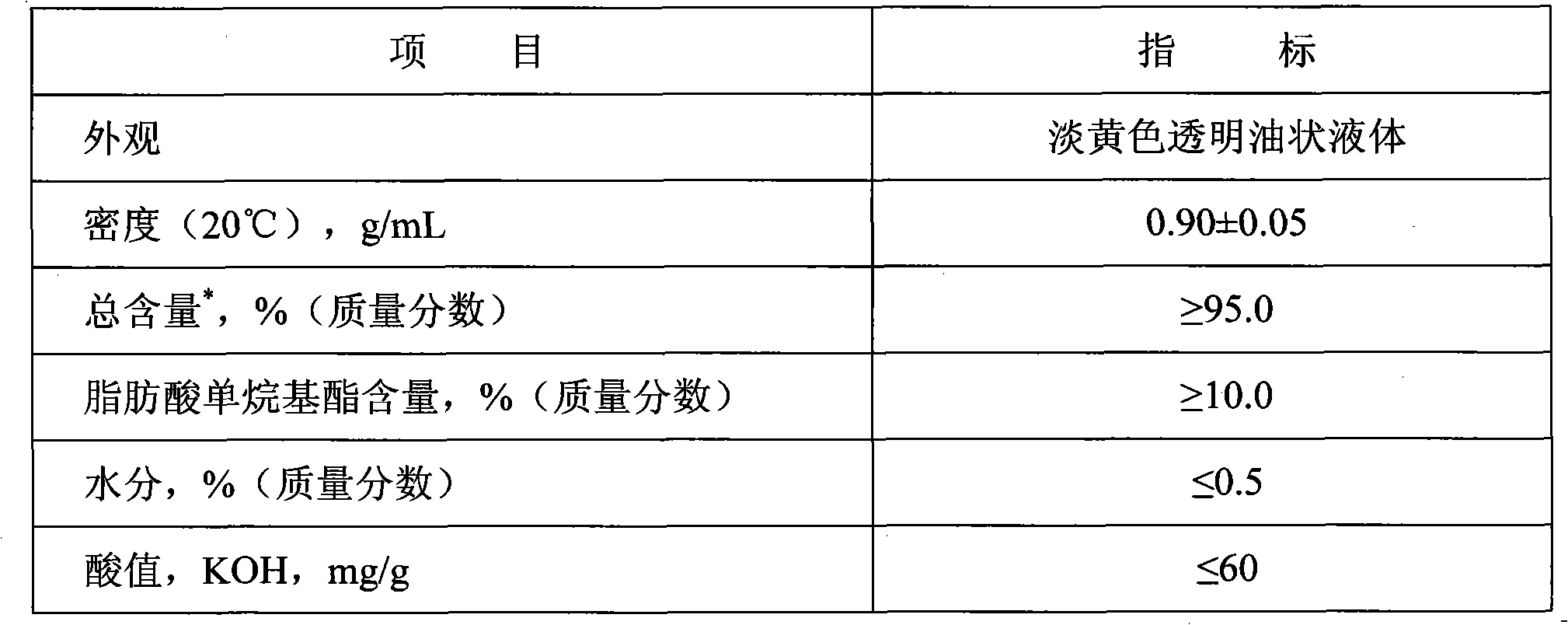

[0027] Table 2

[0028]

Embodiment 2

[0030] Put 180kg of methanol and 9kg of potassium hydroxide into a high-shear emulsification and dispersion kettle, add 350kg of turpentine and 450kg of palm oil after mixing, start the high-shear emulsification and dispersion unit, raise the temperature to 65°C for 45 minutes, and separate and remove impurities to obtain 885kg Pine resin-based vegetable oil, sampling test, the physical and chemical properties of the product are shown in Table 3.

[0031] Example 2 See Table 4 for the comparison of the solubility (g / L, 25° C.) of turpentine-based vegetable oil and xylene to pesticide active components. It can be seen from Table 4 that the pine resin-based vegetable oil in this example significantly improves the solubility of the pesticide components, and has good compatibility with pesticides.

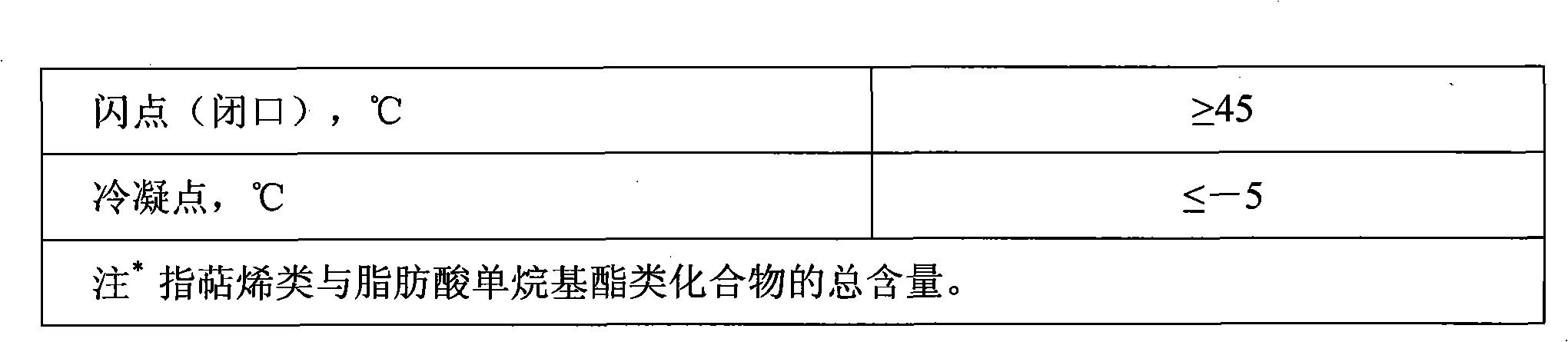

[0032] table 3

[0033]

[0034] Table 4

[0035] Original drug name

Embodiment 3

[0037] Put 200kg of butanol and 9.5kg of potassium hydroxide into a high-shear emulsification and dispersing kettle, add 200kg of turpentine and 800kg of cottonseed oil after mixing, start the high-shear emulsification and dispersing unit, raise the temperature to 70°C for 30 minutes, and separate and remove impurities Get 1095kg turpentine base vegetable oil, sampling detects, and the physicochemical property of product is referring to Table 5.

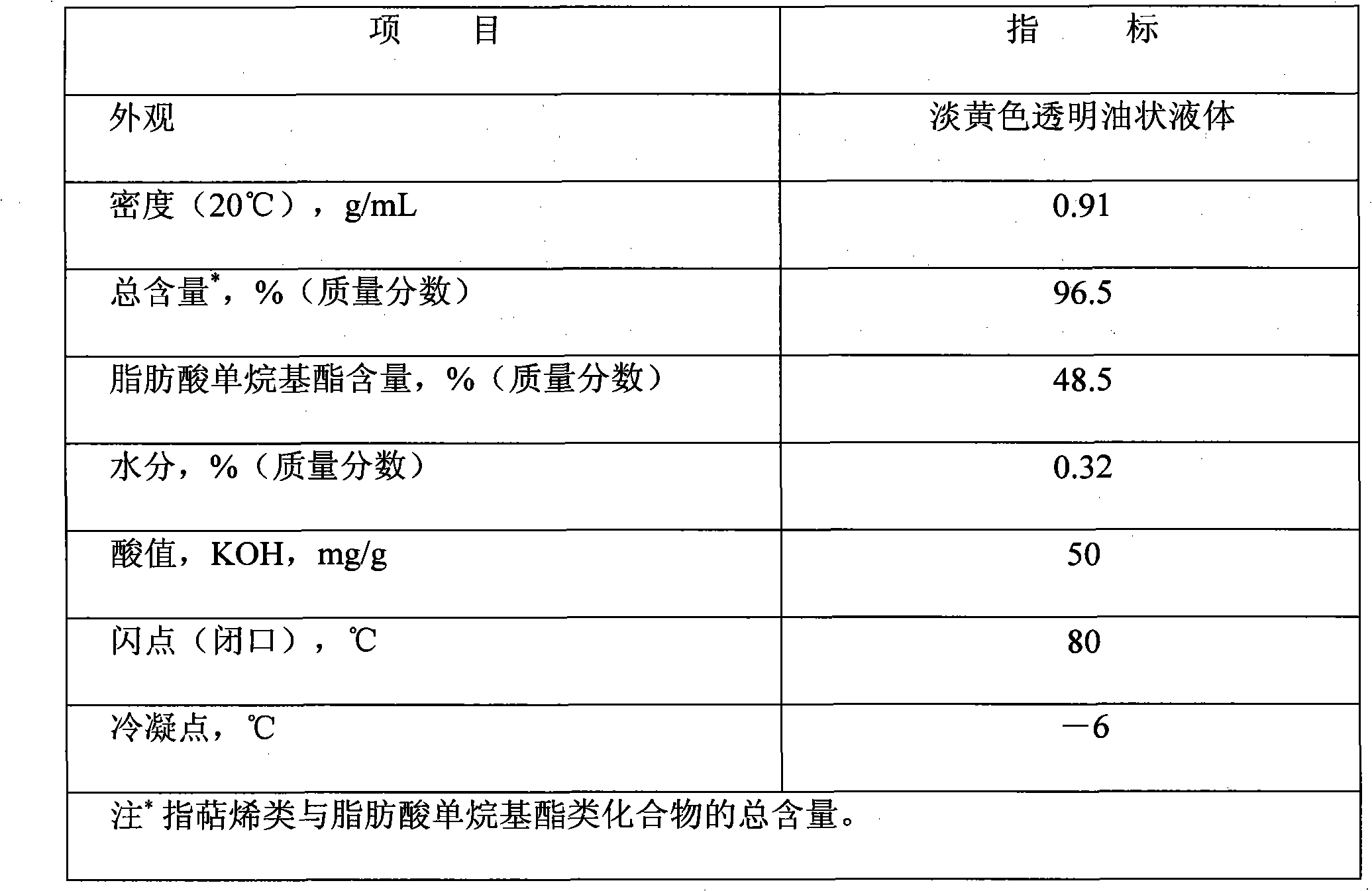

[0038] table 5

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com