Acidic ionic liquid, cleaning agent containing acidic ionic liquid and semiconductor substrate cleaning method

A technology for acidic ionic liquids and semiconductors, applied in chemical instruments and methods, semiconductor/solid-state device manufacturing, non-surface active detergent compositions, etc. Cleaning process and other issues, to achieve the effect of excellent full-process cleaning performance, excellent full-process universality, and simplified operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

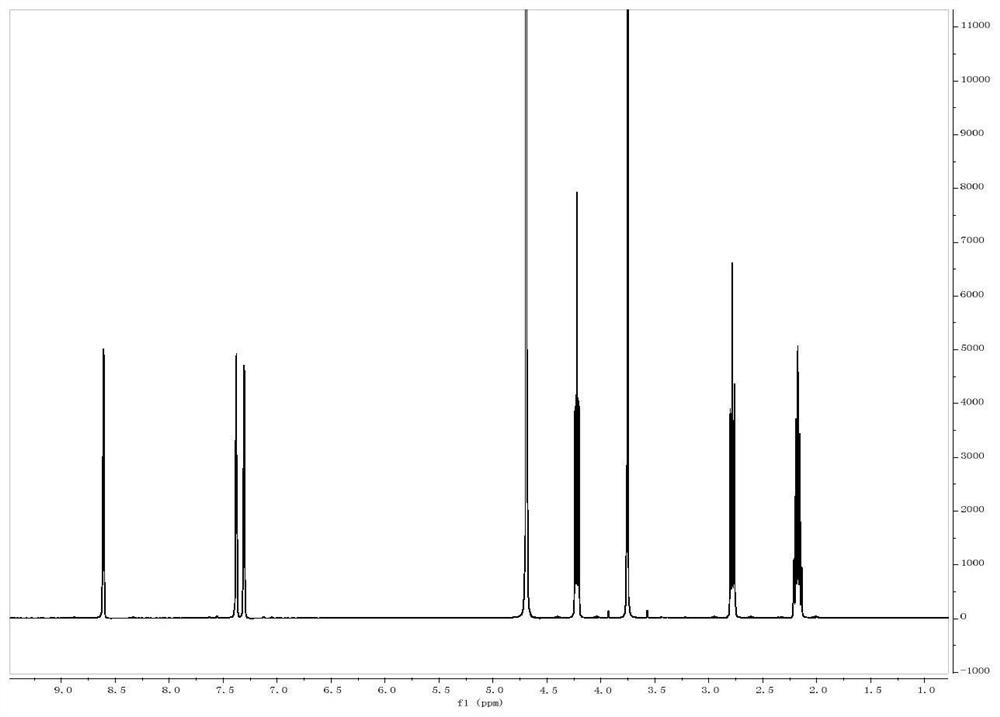

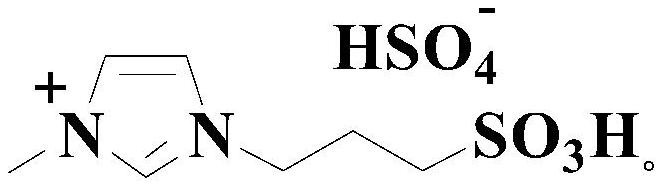

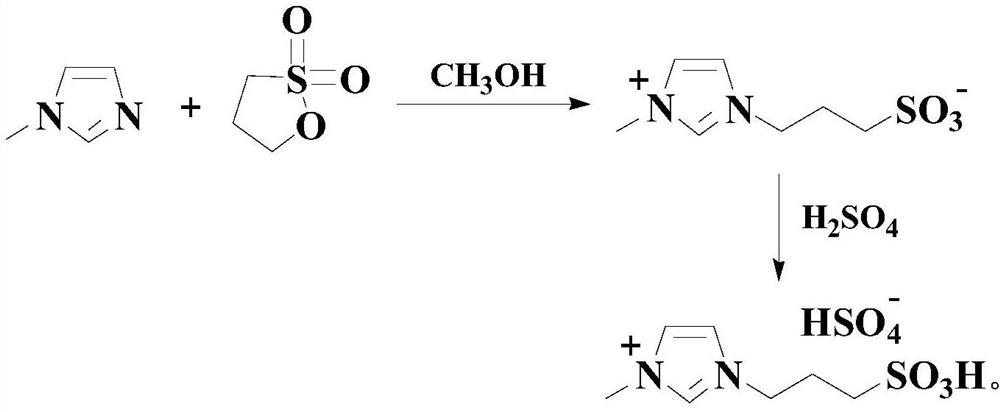

[0084] 1, the preparation of precursor crude product

[0085] Under the oil bath of 40°C, add 1,3-propane sultone into an appropriate amount of methanol, and then add N-methylimidazole dropwise after it is completely dissolved. After completion, leave standstill to separate out the solid, and suction filtration obtains the crude precursor product;

[0086] Wherein, the molar ratio of 1,3-propane sultone to N-methylimidazole is 1:1.2.

[0087] II. Recrystallization of precursors

[0088] The crude precursor product was added to an appropriate amount of methanol, and after all dissolved, heated to reflux, filtered while hot, the filtrate was allowed to stand until crystals were precipitated, the crystals were filtered out, washed with tetrahydrofuran for many times, and dried under vacuum at 80 ° C to obtain the precursor;

[0089] III. Preparation of ionic liquids

[0090] The precursor was mixed with an aqueous sulfuric acid solution with a concentration of 50% by mass, sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com