Double-sided different-color functional thin real silk fabric and method thereof

A silk fabric, double-sided different color technology, applied in the direction of dyeing, textiles and papermaking, can solve the problems of weakening color paste penetration, complex printing and dyeing process, difficult operation, etc., to achieve excellent antistatic, excellent water repellency, easy price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Mix 25.0 g of powdered carbon black CT-5, 4.0 g of commercially available liquid organic paint red, 7.5 g of abrasive AL50 and 63.5 g of water, and grind in a high-speed zirconia medium for 4 hours to prepare a carbon black paint mixture red.

Embodiment 2

[0067] First, prepare the dyeing solution and pad dyeing, mix 10.0 grams of carbon black paint mixture red (Example 1), 10.0 grams of binder HF, 10.0 grams of cross-linking agent SJ, 1.5 grams of leveling agent MP, and 68.5 grams of water, and stir evenly. , the dyeing solution was prepared. Then, the silk georgette fabric was padded with the above dyeing solution, the rolling ratio was 80%, and dried at 90° C. to obtain the dyed silk georgette semi-finished product.

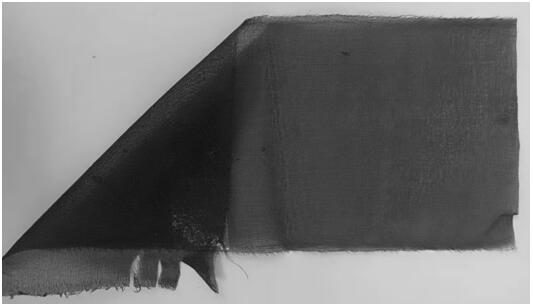

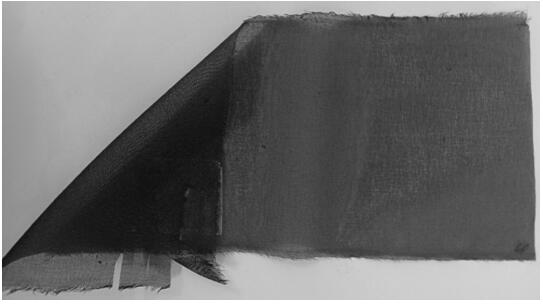

[0068] Next, prepare printing paste and printing, mix 3.0 grams of commercially available liquid organic paint red, 5.0 grams of mortar FY-161, 8.0 grams of adhesive HF, 2.0 grams of synthetic thickener PTF-A, and 82.0 grams of water, and stir evenly. , the printing paste was obtained. Then, conventional printing, baking and drying were carried out on the dyed silk georgette semi-finished product prepared above, and the baking temperature was 150° C. and the baking time was 2.5 minutes. After the baking is com...

Embodiment 3

[0070] First, the dyed silk georgette semi-finished product was prepared with reference to Example 2. Next, referring to Example 2, 3.0 grams of commercially available liquid organic paint yellow was used to replace 3.0 g of commercially available liquid organic paint red to obtain a double-sided two-color thin silk georgette fabric, and the conditions were the same as those in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com