Preparation method of chalcogenide glass infrared compound eye

A technology of chalcogenide glass and compound eyes, which is applied in the field of refraction infrared micro-optical device preparation, can solve the problems of low energy damage threshold of compound eye structure, high production cost of compound eye preparation process, poor thermal stability, etc., and achieves the advantages of large-scale production and Application, the effect of good surface optical smoothness and low softening temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A preparation method of chalcogenide glass infrared compound eye, comprising the following main steps:

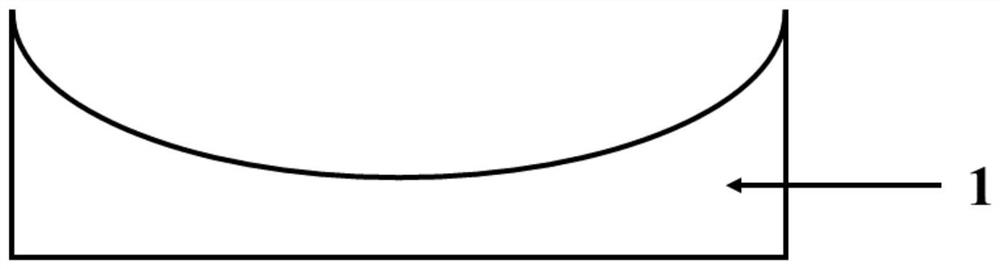

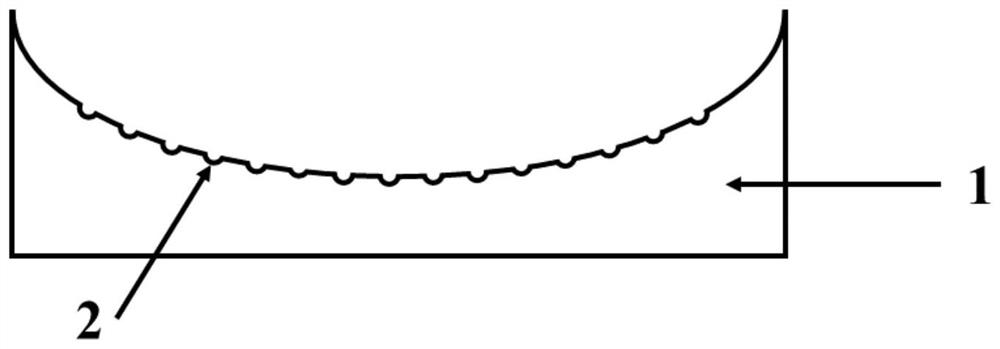

[0063] 1) Sample cleaning: figure 1 , figure 2 The curved K9 glass substrate shown is cleaned in an ultrasonic water bath with acetone, alcohol, and deionized water for 5 minutes in order to remove impurities on the surface of the curved K9 glass substrate, and then dried for use;

[0064] 2) Femtosecond laser modification: use a femtosecond laser beam with a center wavelength of 800nm, a pulse width of 50fs, a repetition frequency of 1KHz, and an energy of 17mW to focus on the surface of the curved K9 glass substrate through a 20x optical focusing lens, focusing on the numerical aperture of the objective lens is 0.45, the curved K9 glass substrate is fixed on the three-dimensional translation stage, and the movement of the three-dimensional translation stage is controlled by a computer program. The action time of the femtosecond laser at each irradiation point is ...

Embodiment 2

[0069] A preparation method of chalcogenide glass infrared compound eye, comprising the following main steps:

[0070]1) Sample cleaning: Clean the curved K9 glass substrate with acetone, alcohol, and deionized water in an ultrasonic water bath for 8 minutes in turn, remove impurities on the surface of the curved K9 glass substrate, and dry it for later use;

[0071] 2) Femtosecond laser modification: use a femtosecond laser beam with a center wavelength of 800nm, a pulse width of 50fs, a repetition frequency of 1KHz, and an energy of 14mW to focus on the surface of the curved K9 glass substrate through a 15x optical focusing lens, focusing on the numerical aperture of the objective lens is 0.35, the curved K9 glass substrate is fixed on the three-dimensional translation stage, and the movement of the three-dimensional translation stage is controlled by a computer program. The action time of the femtosecond laser at each irradiation point is 500ms. A plurality of ablation crat...

Embodiment 3

[0076] A preparation method of chalcogenide glass infrared compound eye, comprising the following main steps:

[0077] 1) Sample cleaning: Clean the curved K9 glass substrate with acetone, alcohol, and deionized water in an ultrasonic water bath for 10 minutes in turn, remove impurities on the surface of the curved K9 glass substrate, and dry it for later use;

[0078] 2) Femtosecond laser modification: use a femtosecond laser beam with a center wavelength of 800nm, a pulse width of 50fs, a repetition frequency of 1KHz, and an energy of 25mW to focus on the surface of the curved K9 glass substrate through a 20x optical focusing lens, focusing on the numerical aperture of the objective lens is 0.6, the curved K9 glass substrate is fixed on the three-dimensional translation stage, and the movement of the three-dimensional translation stage is controlled by a computer program. The action time of the femtosecond laser at each irradiation point is 500ms. A plurality of ablation cra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com