Embedded flash memory and preparation method thereof

An embedded and flash memory technology, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of increased leakage current of small-sized embedded flash memory, and achieve the effect of reducing leakage current, satisfying the gradual reduction of area, and reducing the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

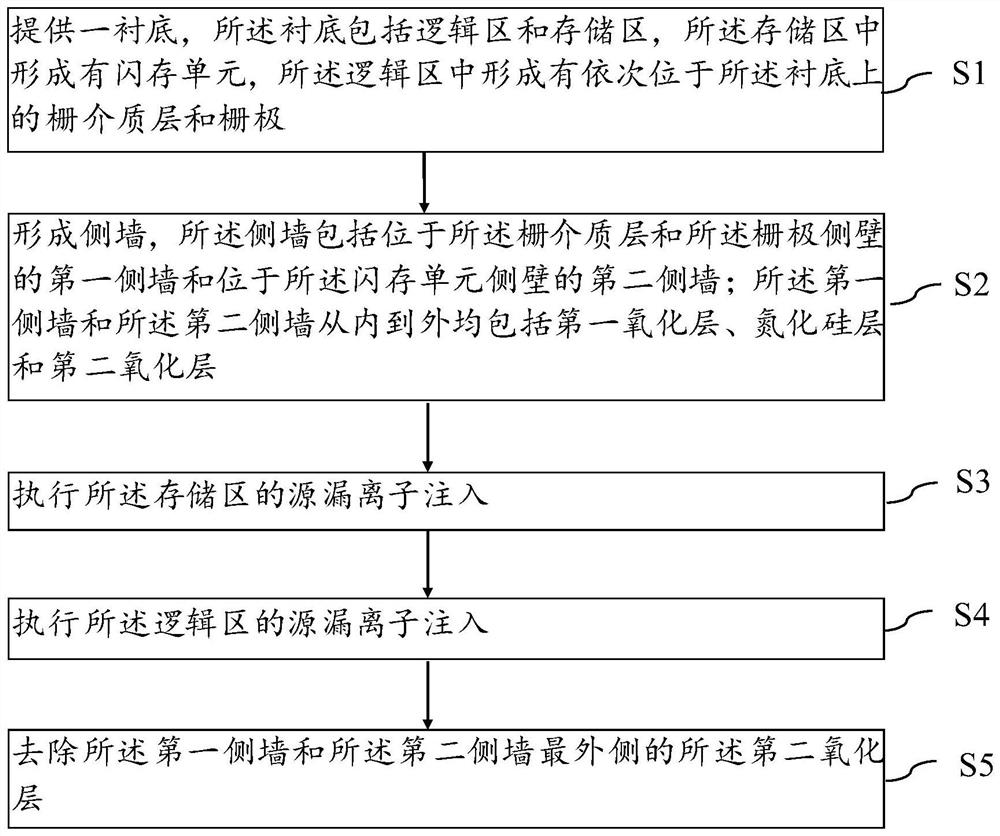

[0047] Embodiments of the present invention provide a method for preparing an embedded flash memory, such as figure 1 shown, including:

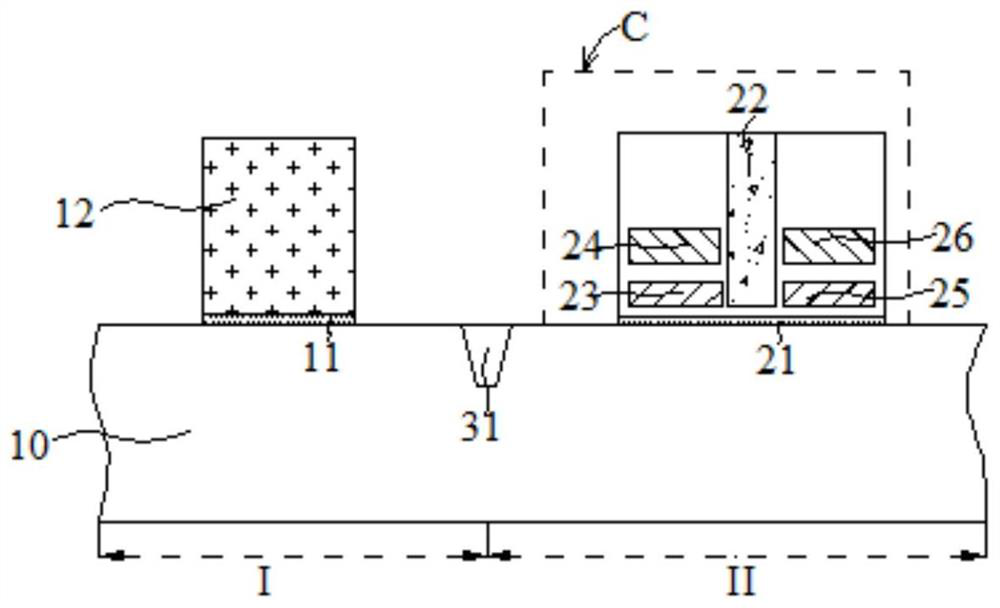

[0048] Step S1, providing a substrate, the substrate includes a logic area and a storage area, flash memory cells are formed in the storage area, and a gate dielectric layer and a gate electrode sequentially located on the substrate are formed in the logic area ;

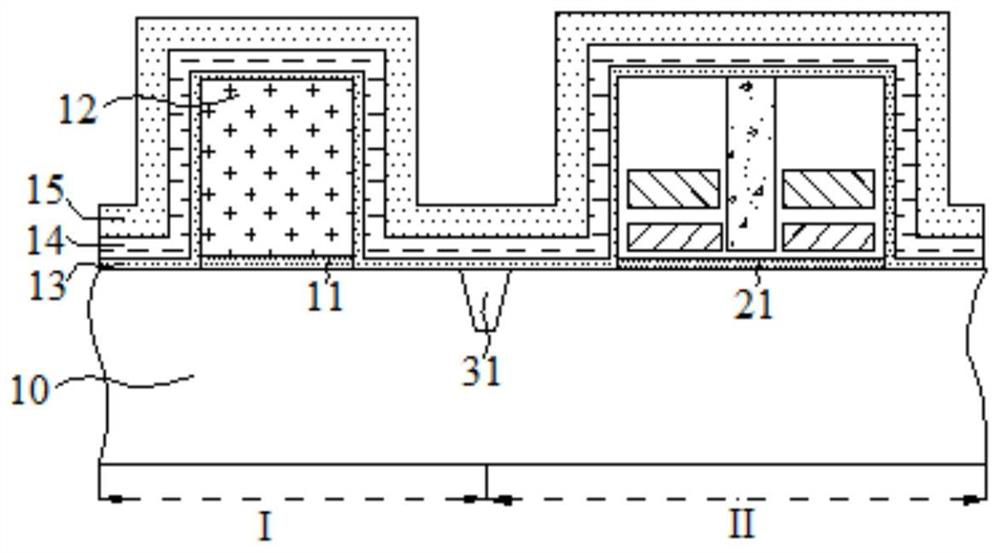

[0049] Step S2, forming spacers, including a first spacer located on the sidewall of the gate dielectric layer and the gate, and a second spacer located on the sidewall of the flash memory cell; the first spacer and the second spacer includes a first oxide layer, a silicon nitride layer and a second oxide layer from inside to outside;

[0050] Step S3, performing source-drain ion implantation of the storage area;

[0051] Step S4, performing source-drain ion implantation of the logic region;

[0052]Step S5, removing the second oxide layer on the outermost side of the first sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com