Electrolyte additive, electrolyte and application in magnesium metal secondary battery

An electrolyte additive and secondary battery technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as hindering the penetration of Mg2+, limiting the optional range of magnesium electrolyte components, and uneven growth of magnesium metal. Achieve the effect of facilitating industrialization promotion and application, improving interface compatibility, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

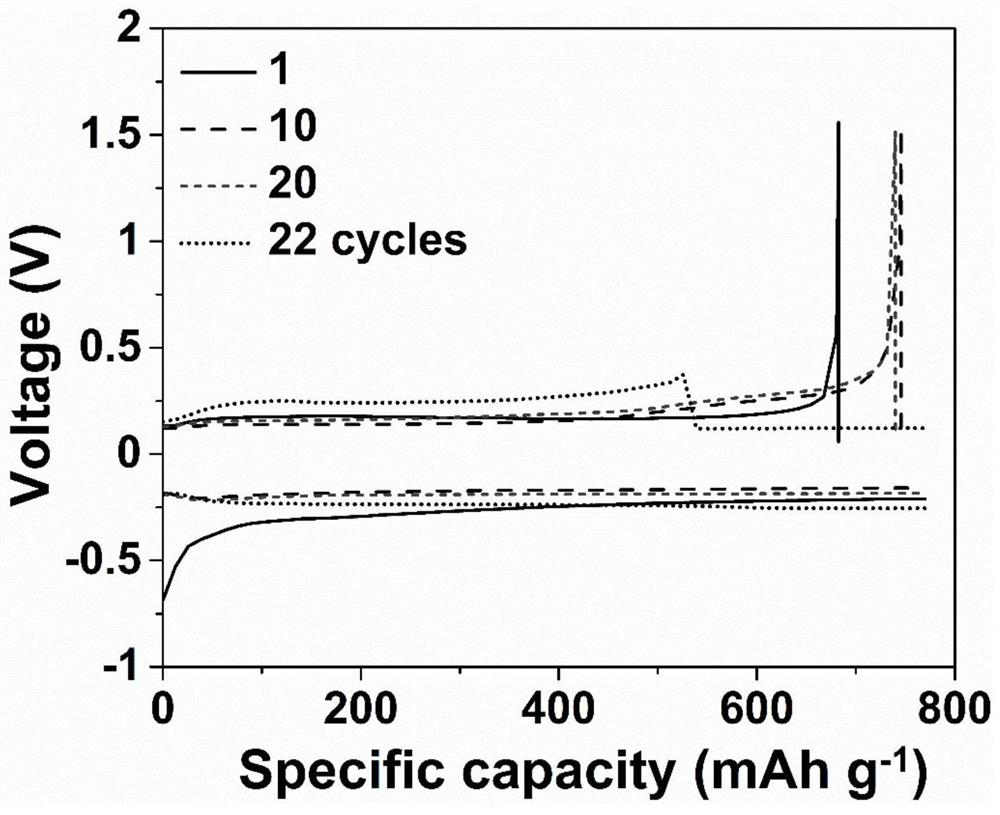

Embodiment 1

[0029] Magnesium electrolyte, which comprises magnesium salt, organic solvent and electrolyte additive, wherein, the magnesium salt is magnesium bis-trifluoromethylsulfonimide and magnesium chloride, and the concentrations are respectively 0.25mol / L and 0.5mol / L; the solvent is ethyl acetate Glycol dimethyl ether; the electrolyte additive is bismuth trichloride, and the weight percentage in the electrolyte is 1%wt.

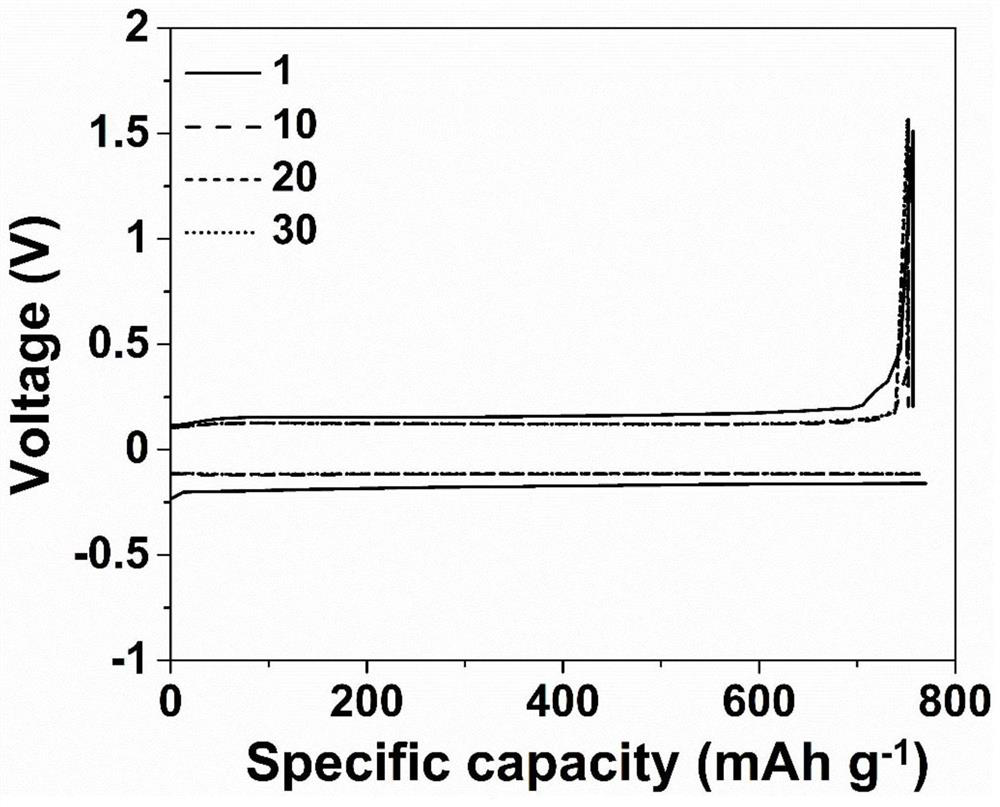

Embodiment 2

[0031] Magnesium electrolyte, which comprises magnesium salt, organic solvent and electrolyte additive, wherein, the magnesium salt is magnesium bis-trifluoromethylsulfonimide and magnesium chloride, and the concentrations are respectively 0.25mol / L and 0.5mol / L; the solvent is ethyl acetate Glycol dimethyl ether; the electrolyte additive is tin tetrachloride, and the weight percentage in the electrolyte is 1%wt.

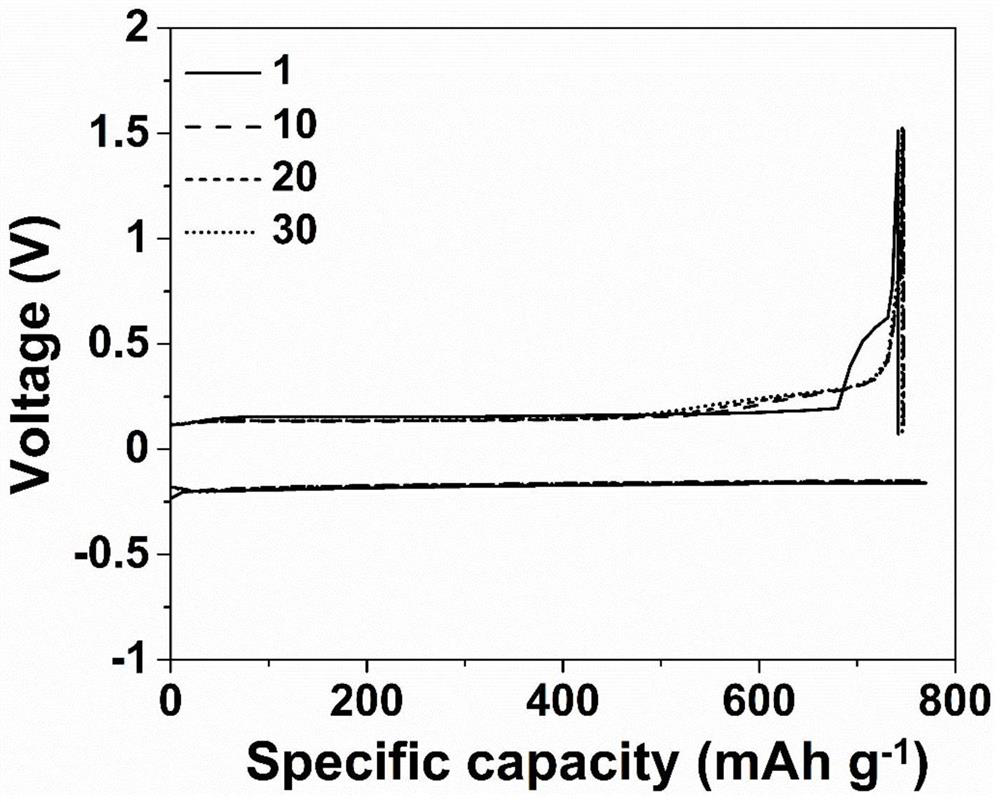

Embodiment 3

[0033] Magnesium electrolyte, which comprises magnesium salt, organic solvent and electrolyte additive, wherein, the magnesium salt is magnesium bis-trifluoromethylsulfonimide and magnesium chloride, and the concentrations are respectively 0.25mol / L and 0.5mol / L; the solvent is ethyl acetate Glycol dimethyl ether; the electrolyte additive is aluminum trichloride, and the weight percentage in the electrolyte is 1%wt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com