High-power laser hollow-core optical fiber gas filling coupling terminal

A hollow-core fiber, high-power technology, used in lasers, laser parts, laser parts, etc., can solve the problems of poor heat dissipation performance and bulky sealed gas cavity, avoid thermal damage, ensure purity, efficient gain and stability. Effect of laser output performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

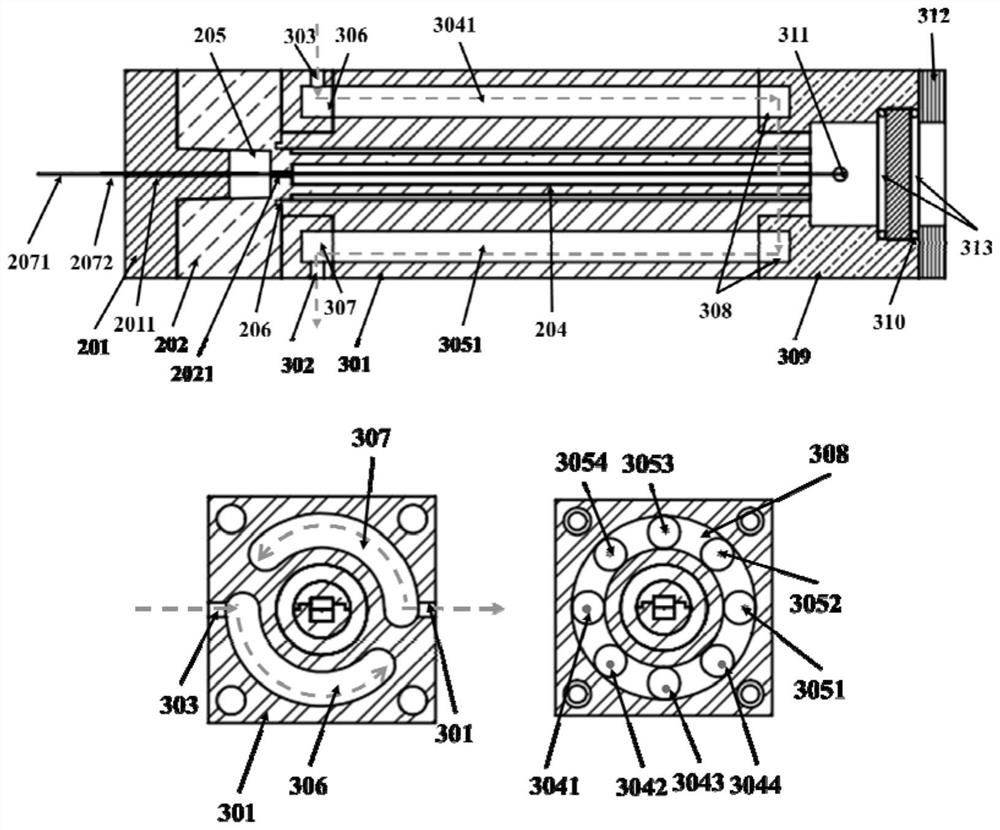

[0040] In order to make those skilled in the art better understand the solution of the present invention, the present invention will be clearly and completely described below with reference to the embodiments of the present invention and the accompanying drawings. Obviously, the described embodiments are only a part of the present invention. , not all examples. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work shall fall within the protection scope of the present invention

[0041]The terms "first", "second", "third", "fourth", etc. (if any) in the description and claims of the present invention and the above-mentioned drawings are used to distinguish similar objects and are not necessarily used to describe a specific order or sequence. It is to be understood that data so used may be interchanged under appropriate circumstances so that the embodiments described herein can be practiced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com