Antifogging coating composition, antifogging coating film, and antifogging article

An anti-fog coating and composition technology, applied in the field of anti-fog coating composition, anti-fog coating film and anti-fog articles, can solve problems such as reduction of irradiated light intensity, safety problem, aesthetic problem, etc. The amount of light, the effect of preventing diffuse reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2 and comparative example 1~2

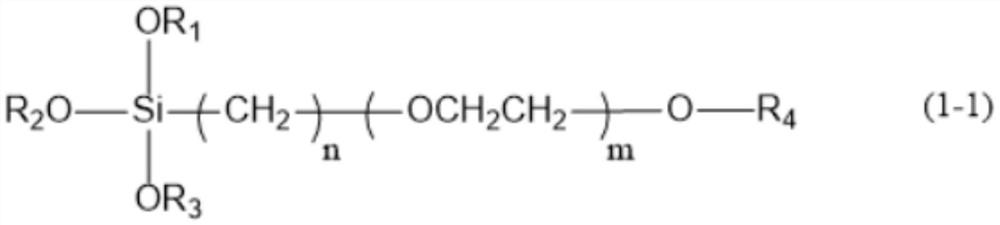

[0151]Examples 1 to 2 and Comparative Examples 1 to 2 are experimental examples in which the types and compounding amounts of the silane derivative compounds were changed. The anti-fogging coating films of Examples 1 to 2 in which the silane derivative compound having a polyethylene glycol chain in the molecule and the silane derivative compound having an epoxy group in the molecule were used in combination were excellent in coating properties, anti-fogging properties, and adhesion. Good results were shown in all aspects of the properties, and after the moist heat resistance test and the heat resistance test, good results were also shown in the anti-fogging property and the adhesiveness. Comparative Example 1 did not prepare a silane derivative compound having an epoxy group in the molecule. The antifogging coating film of Comparative Example 1 showed a decrease in adhesiveness after the moist heat resistance test. In Comparative Example 2, a silane derivative compound not be...

Embodiment 1~2 and comparative example 3~5

[0153] Examples 1 to 2 and Comparative Examples 3 to 5 are experimental examples in which the amount of diacetone alcohol as the organic solvent was changed. Regarding the antifogging coating film formed from the antifogging coating composition of Comparative Example 3 in which diacetone alcohol was not formulated, it was found that the adhesiveness after the heat-and-moisture resistance test decreased. Regarding the anti-fogging coating film of Comparative Example 4 in which 0.86% by weight of diacetone alcohol was added to the anti-fog coating composition, it was found that the adhesion after the heat and humidity resistance test decreased. The antifogging coating film of Comparative Example 5 of alcohol was inferior in coatability.

Embodiment 3~8

[0155] Examples 3 to 8 are experimental examples in which the type and compounding amount of the silane derivative compound were changed. In all of Examples 3 to 8, a silane derivative compound having a polyethylene glycol chain in the molecule and a silane derivative compound having an epoxy group in the molecule were used in combination. The anti-fogging coating films of Examples 3 to 8 showed good results in all aspects of coating properties, anti-fogging properties, and adhesive properties, and also showed good results in anti-fogging properties and adhesive properties after the water resistance test. The antifogging property and adhesiveness after the thermal test also showed favorable results. Even if a silane derivative compound (acetylsilane) having a polyethylene glycol chain and an acyl group in the molecule is used as the silane derivative compound having a polyethylene glycol chain in the molecule (Example 4), a polyethylene glycol having a Silane derivative compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com