Preparation method of low-energy ovalbumin compound leisure food

A technology for ovalbumin and snack food, which is applied in the field of food processing and preparation, can solve the problems of difficult preservation of ovalbumin during shelf life, large eggy smell of ovalbumin, and difficulty in shaping, etc., so as to meet the requirements of healthy snack food and be tolerant of taste. Sexual, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

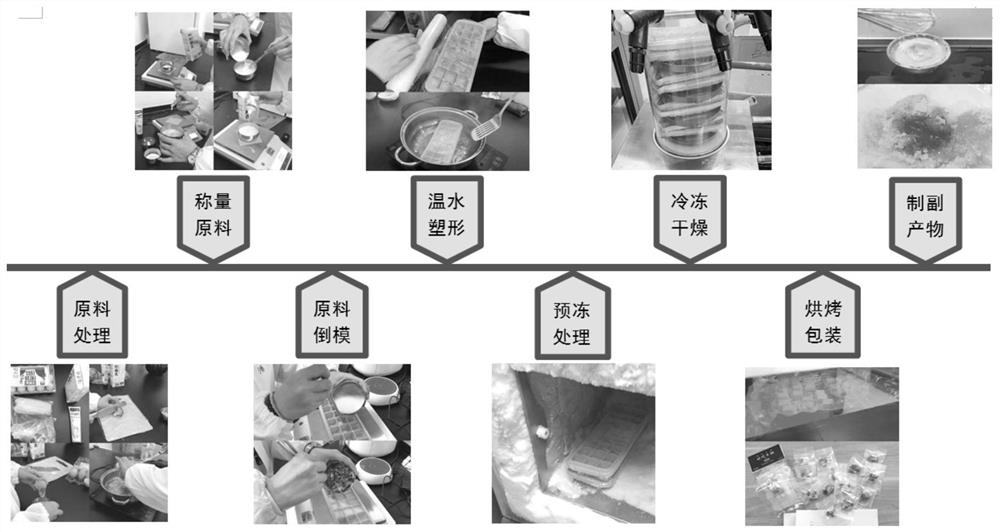

[0027] A preparation method of low-energy ovalbumin compound snack food - Mushu Crisp:

[0028] (1) Preparation of raw materials: take the eggs according to the recipe, separate the ovalbumin after shelling, let it stand for defoaming, take the ratio of coconut milk and egg white to 1:3 for later use; wash vegetables such as corn and broccoli, and blanch in boiling water for 3- 5min, remove and chop and set aside;

[0029] (2) Weigh the raw and auxiliary materials in proportion and fill: Weigh 10-15g of egg white protein and coconut milk and mix them evenly, add 2-3g of condensed milk and 1-2g of miscellaneous grains (such as white sesame), mix well and pour into the food Grade silica gel ice tray to 2 / 3 height, and then evenly fill 0.5-0.8g chopped vegetables;

[0030] (3) Warm water shaping: add TGase equivalent to 0.03-0.07% of the sample mass, mix well, and take it out in a water bath (50℃~55℃) for 10 minutes to obtain a protein-colored jelly block;

[0031] (4) Pre-free...

Embodiment 2

[0035] A preparation method of low-energy ovalbumin compound snack food - Mushu Crisp:

[0036] (1) Preparation of raw materials: take the eggs according to the formula, separate the ovalbumin after shelling, let it stand for defoaming, take the ratio of coconut milk and egg white to 1:3.2 for later use; wash vegetables such as corn and broccoli, and blanch in boiling water for 3- 5min, remove and chop and set aside;

[0037] (2) Weigh the raw and auxiliary materials according to the proportion and fill: Weigh 10-15g of egg white protein and coconut milk and mix them evenly, add 12-13g of condensed milk and 1-2g of miscellaneous grains (such as white sesame), mix well and pour into the food Grade silica gel ice tray to 2 / 3 height, and then evenly fill 1-5g chopped vegetables;

[0038] (3) Warm water shaping: add TGase equivalent to 0.03-0.07% of the sample mass, mix well, and take it out in a water bath (50℃~55℃) for 10 minutes to obtain a protein-colored jelly block;

[003...

Embodiment 3

[0043] A preparation method of low-energy ovalbumin compound snack food - Mushu Crisp:

[0044] (1) Preparation of raw materials: take the eggs according to the formula, separate the ovalbumin after shelling, let stand for defoaming, take the ratio of coconut milk and egg white to 1:3 for use; wash vegetables such as corn and broccoli, and blanch in boiling water for 3- 5min, remove and chop and set aside;

[0045](2) Weigh the raw and auxiliary materials in proportion and fill: Weigh 10-15g ovalbumin and coconut milk and mix them evenly, add 2-3g condensed milk and 1-2g miscellaneous grains (such as white sesame), mix well and pour into food grade Silicone ice tray to 2 / 3 height, and then evenly fill 1g chopped vegetables;

[0046] (3) Warm water shaping: add TGase equivalent to 0.03-0.07% of the sample mass, mix well, and take it out in a water bath (50°C-55°C) for 10 minutes to obtain protein-colored jelly chunks;

[0047] (4) Pre-freezing: freeze for 3-5 hours in a refri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com