Separation and purification process and system of 1, 4-butanediol

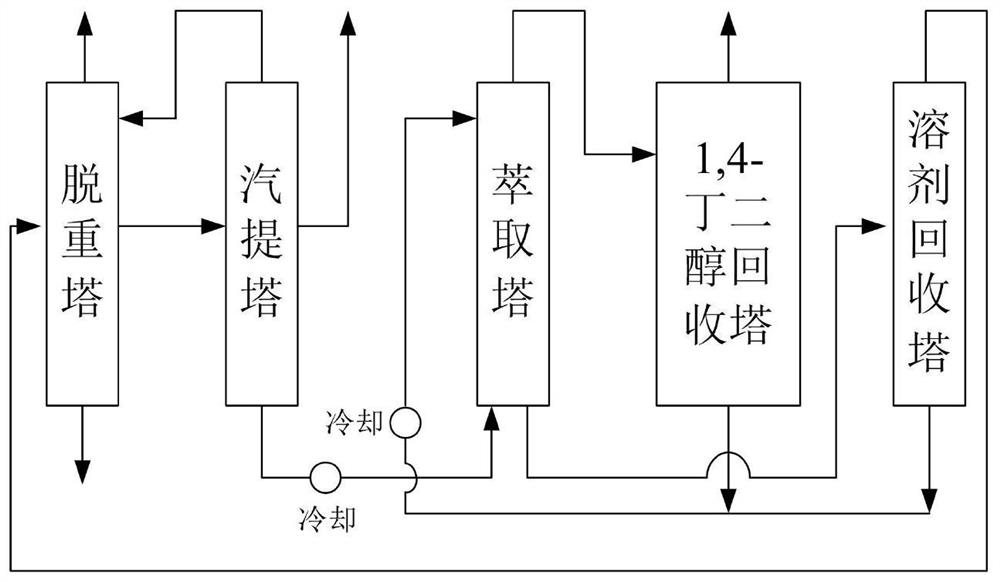

A technology for separation and purification of butanediol, applied in the separation/purification of hydroxyl compounds, organic chemistry, production of bulk chemicals, etc., can solve the problem of low purity of 1,4-butanediol, and achieve simple equipment and separation efficiency High, high product purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The embodiment of the present invention provides a separation and purification process of 1,4-butanediol, and the process includes:

[0044] S101: Crude 1,4-butanediol is separated in a weight-removing column. Among them, the content of 1,4-butanediol is 80.1wt%, the content of 2-(4-hydroxybutoxy)tetrahydrofuran is 0.6wt%, the content of light components is 17.1wt%, and the content of other heavy components is 2.2 wt%. Light components such as γ-butyrolactone and unreacted dimethyl succinate are extracted from the top of the weight removal tower; 1,4-butanediol and 2-(4-hydroxybutoxy)tetrahydrofuran are extracted from the side line The mixture a; the bottom of the column produced 2-(4-hydroxybutoxy) tetrahydrofuran and other heavy components. The packing height of the weight-removing tower is 50 theoretical trays, the operating pressure is 10kPa, the reflux ratio is 8, the temperature at the top of the tower is 180°C, and the temperature at the bottom of the tower is ...

Embodiment 2

[0051] The embodiment of the present invention provides a separation and purification process of 1,4-butanediol, and the process includes:

[0052] S201: Crude 1,4-butanediol is separated in a weight removal tower. Among them, the content of 1,4-butanediol is 80.1wt%, the content of 2-(4-hydroxybutoxy)tetrahydrofuran is 0.6wt%, the content of light components is 17.1wt%, and the content of other heavy components is 2.2 wt%. Light components such as γ-butyrolactone and unreacted dimethyl succinate are extracted from the top of the weight removal tower; 1,4-butanediol and 2-(4-hydroxybutoxy)tetrahydrofuran are extracted from the side line The mixture a; the bottom of the column produced 2-(4-hydroxybutoxy) tetrahydrofuran and other heavy components. The packing height of the weight-removing tower is 10 theoretical trays, the operating pressure is 5kPa, the reflux ratio is 5, the temperature at the top of the tower is 160°C, and the temperature at the bottom of the tower is 180...

Embodiment 3

[0059] The embodiment of the present invention provides a separation and purification process of 1,4-butanediol, and the process includes:

[0060] S301: Crude 1,4-butanediol is separated in a weight removal tower. Among them, the content of 1,4-butanediol is 80.1wt%, the content of 2-(4-hydroxybutoxy)tetrahydrofuran is 0.6wt%, the content of light components is 17.1wt%, and the content of other heavy components is 2.2 wt%. Light components such as γ-butyrolactone and unreacted dimethyl succinate are extracted from the top of the weight removal tower; 1,4-butanediol and 2-(4-hydroxybutoxy)tetrahydrofuran are extracted from the side line The mixture a; the bottom of the column produced 2-(4-hydroxybutoxy) tetrahydrofuran and other heavy components. The packing height of the weight-removing tower is 50 theoretical trays, the operating pressure is 25kPa, the reflux ratio is 10, the temperature at the top of the tower is 200°C, and the temperature at the bottom of the tower is 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com