Low-temperature solid-phase method for simply and efficiently preparing rare earth nano luminescent material

A kind of rare earth nanomaterials, high-efficiency technology, applied in the direction of luminescent materials, chemical instruments and methods, climate sustainability, etc., can solve the problems of lowering the reaction temperature, long reaction time, and incapable of large-scale preparation. The effect of lifting, lowering the threshold of equipment conditions, and shortening the action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

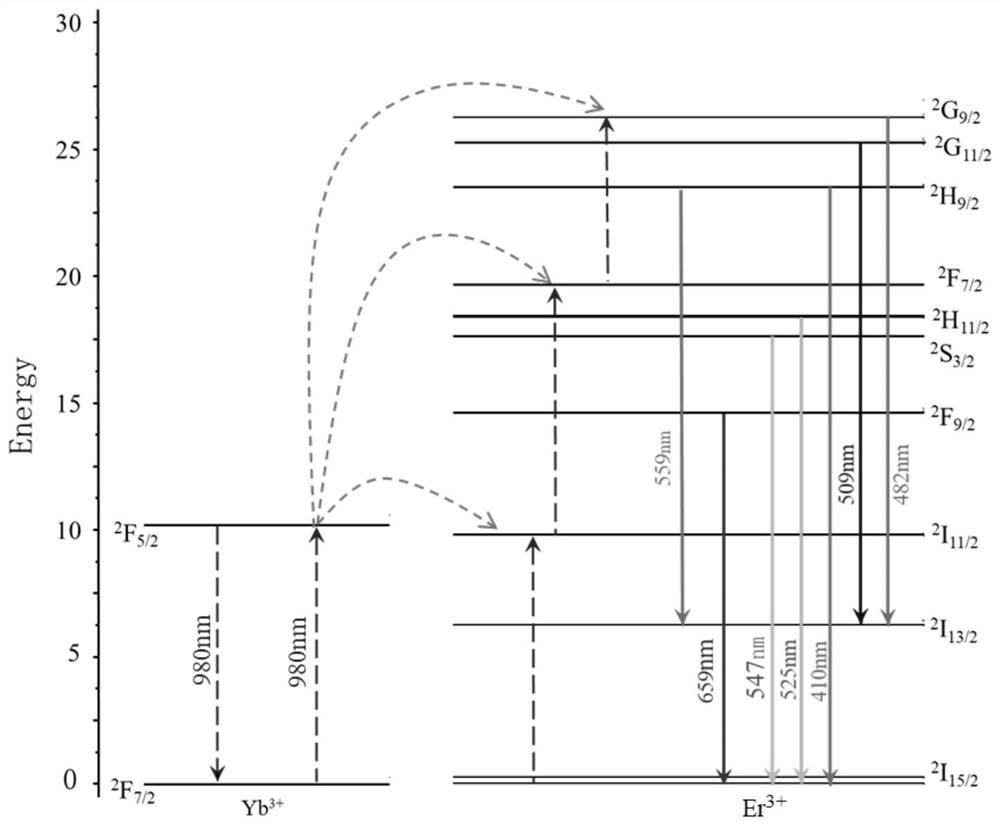

[0032] Example 1 (upconversion material)

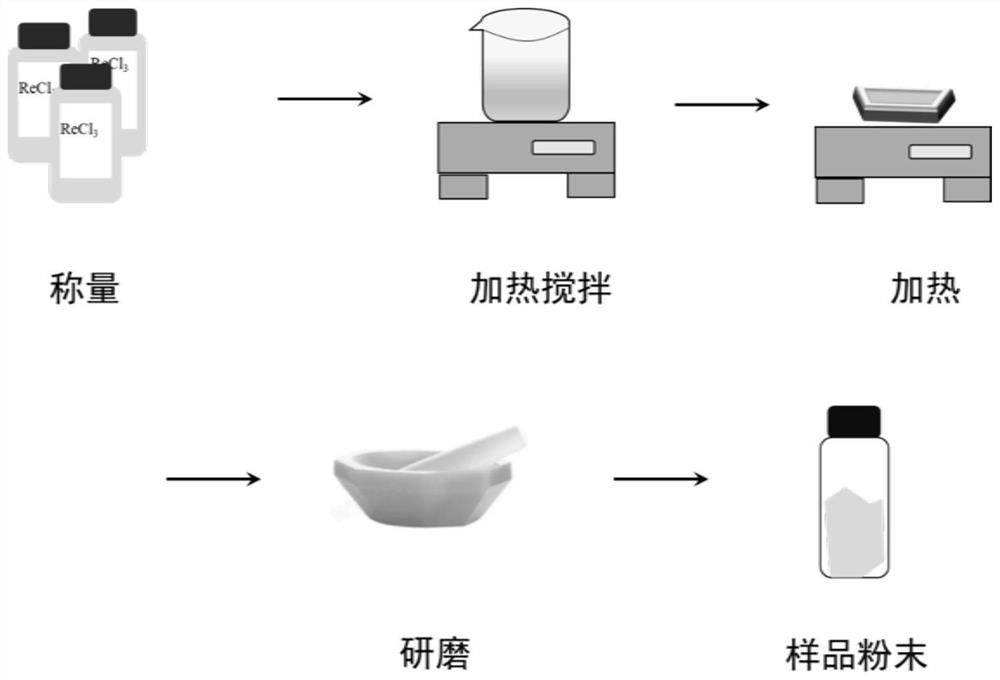

[0033] like figure 1 shown to prepare NaF 4 : 7Yb, 1Er as an example, further state the method of the present invention.

[0034] S1 takes the amount of preparing 6 mmol as an example, and weighs NaF and YbCl respectively 3 , ErCl 3 (molar ratio of 0.78:0.2:0.02), it was placed in a 50 mL beaker, 40 mL of water was added, and the solid was dissolved under magnetic stirring.

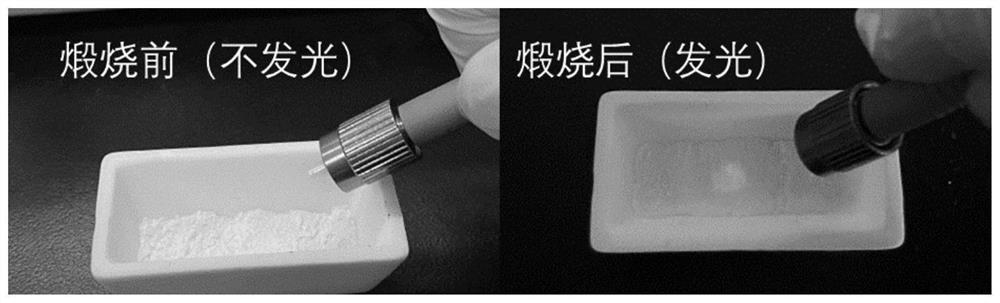

[0035] S2 Place the beaker on the heating table, set the temperature to 90 °C, and heat while stirring. After the reaction for about 1 hour, the water is completely volatilized, and the heating is stopped when the remaining dry white powder.

[0036] S3 collect the white powder in the beaker in a corundum crucible, place it on a heating table, and set the temperature of the heating table to 200°C. When the temperature of the heating table reaches 200°C, the timing is started, and the heating is stopped after 2 hours.

[0037] After S4 stops heating, when th...

Embodiment 2

[0040] Example 2 (down conversion material)

[0041] like figure 1 shown to prepare NaF 4 : 30Yb, 5Er, 5Ce are taken as examples to further state the method of the present invention.

[0042] S1 takes the preparation of 6 mmol as an example, and weighs NaF and YbCl respectively 3 , ErCl 3 , CeCl 3(molar ratio of 0.7:0.2:0.05:0.05), it was placed in a 50 mL beaker, 40 mL of water was added, and the solid was dissolved under magnetic stirring.

[0043] S2 Place the beaker on the heating table, set the temperature to 90 °C, and heat while stirring. After the reaction for about 1 hour, the water is completely volatilized, and the heating is stopped when the remaining dry white powder.

[0044] S3 collect the white powder in the beaker in a corundum crucible, place it on a heating table, and set the temperature of the heating table to 200°C. When the temperature of the heating table reaches 200°C, the timing is started, and the heating is stopped after 2 hours.

[0045] Afte...

Embodiment 3

[0048] Example 3 (down conversion material)

[0049] like figure 1 shown to prepare NaF 4 : 5Eu as an example, further state the inventive method.

[0050] S1 takes the preparation of 6 mmol as an example, and weighs NaF and EuCl respectively. 3 (molar ratio of 0.95:0.05), it was placed in a 50 mL beaker, 40 mL of water was added, and the solid was dissolved under magnetic stirring.

[0051] S2 Place the beaker on the heating table, set the temperature to 90 °C, and heat while stirring. After the reaction for about 1 hour, the water is completely volatilized, and the heating is stopped when the remaining dry white powder.

[0052] S3 collect the white powder in the beaker in a corundum crucible, place it on a heating table, and set the temperature of the heating table to 200°C. When the temperature of the heating table reaches 200°C, the timing is started, and the heating is stopped after 2 hours.

[0053] After S4 stops heating, when the temperature drops to room tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com