Preparation method of FeCo alloy coated foamed nickel wave-absorbing material

A wave-absorbing material and nickel foam technology, which is applied in metal material coating process, liquid chemical plating, coating, etc., can solve the problems of long preparation cycle, large energy consumption, complex process, etc., and achieve low cost and good coating Good effect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

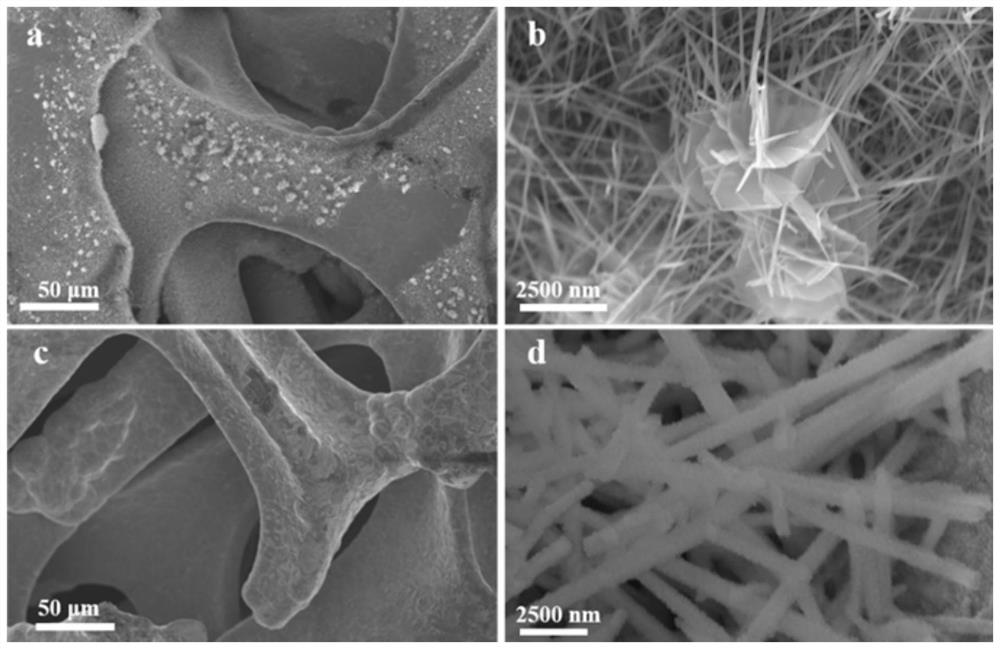

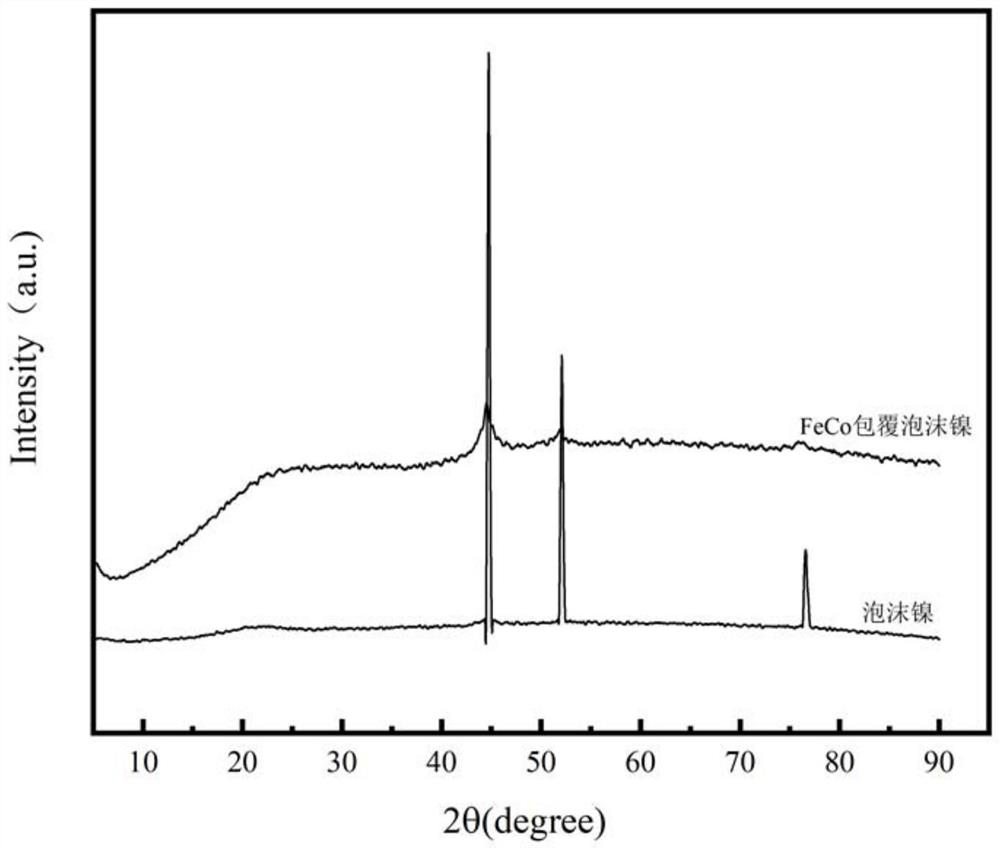

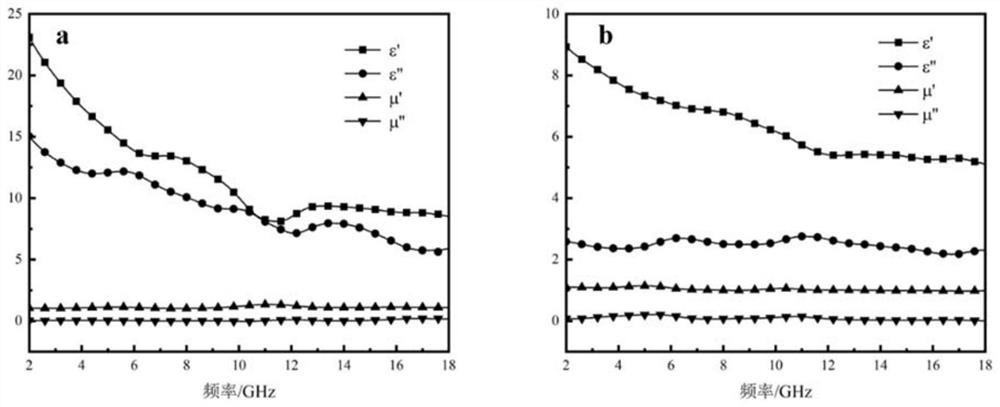

[0029] Example 1: A method for preparing a FECO alloy covering foam nickel -sucking material, including the following steps:

[0030] 1) Foam nickels are cut, cleaned and dry treatment in order, and removal of drying treatment. Among them, when cutting nickels, nickel nickel needs to be cut into 1cm × 1.5cm rectangles, and foam nickel nickel in order Soak in 3M HCL, water -free ethanol, and deodorded water for ultrasound cleaning. Each washed 10min each time, a total of 30 minutes, drying through drying equipment after cleaning;

[0031] 2) FECL of 0.237G 3 · 6H 2 O, 0.474G COCL 2 · 6H 2 O and 0.25g urea mix with 30ml exfoliating water. After stirring for 30 minutes, it gets the water and thermal solution. Among them, FeCL 3 · 6H 2 O, COCL 2 · 6H 2 O and urea's Moore is 1: 2: 4;

[0032] 3) Add dry foam nickel and prepared water and thermal solution to 50ml of reactors, then place the high -pressure reactor in the winding drying box, heat the heat at 130 ° C for 6h, and cool to ro...

Embodiment 2

[0036] Example 2: a method for preparing a FECO alloy covering foam nickel -sucking material, including the following steps:

[0037] 1) Foam nickels are cut, cleaned and dry treatment in order, and removal of drying treatment. Among them, when cutting nickels, nickel nickel needs to be cut into 1cm × 1.5cm rectangles, and foam nickel nickel in order Soak in 3M HCL, water -free ethanol, and deodorded water for ultrasound cleaning. Each washed 10min each time, a total of 30 minutes, drying through drying equipment after cleaning;

[0038] 2) FECL of 0.237G 3 · 6H 2 O, 0.474G COCL 2 · 6H 2 O and 0.25g of urea and 30ml mixing solvents (5: 1) mixed with 30ml exfoliating water and ethanol (5: 1), mix for 30 minutes and get water heat solutions. Among them, FeCL 3 · 6H 2 O, COCL 2 · 6H 2 O and urea's Moore is 1: 2: 4;

[0039] 3) Add dry foam nickel and prepared water and thermal solution to 50ml of reactors, then place the high -pressure reactor in the winding drying box, heat the heat...

Embodiment 3

[0043] Example 3: a method for preparing a FECO alloy covering foam nickel -sucking material, including the following steps:

[0044] 1) Foam nickels are cut, cleaned and dry treatment in order, and removal of drying treatment. Among them, when cutting nickels, nickel nickel needs to be cut into 1cm × 1.5cm rectangles, and foam nickel nickel in order Soak in 3M HCL, water -free ethanol, and deodorded water for ultrasound cleaning. Each washed 10min each time, a total of 30 minutes, drying through drying equipment after cleaning;

[0045] 2) FECL of 0.237G 3 · 6H 2 O, 0.474G COCL 2 · 6H 2 O and 0.25g urea mix with 25ml exfoliating water. After stirring for 30 minutes, the water and thermal solution is obtained. Among them, FeCL 3 · 6H 2 O, COCL 2 · 6H 2 O and urea's Moore is 1: 2: 4;

[0046] 3) Add dry foam nickel and prepared water and thermal solution to 50ml of reactors, then place the high -pressure reactor in the winding drying box, heat the heat at 130 ° C for 6h, and cool t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap