Water-soluble fracturing temporary plugging agent and preparation method thereof

A water-soluble, temporary plugging agent technology, applied in the field of temporary plugging agents, which can solve the problem of difficulty in bridging and enriching the sealing and blocking layer at the same time, a single temporary plugging agent or a mixture of temporary plugging agents, and difficulty in forming a sealing and blocking layer, etc. To solve the problem, achieve the effect of temporary plugging and leakage prevention performance, improving the polymerization rate, stability and leakage prevention performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

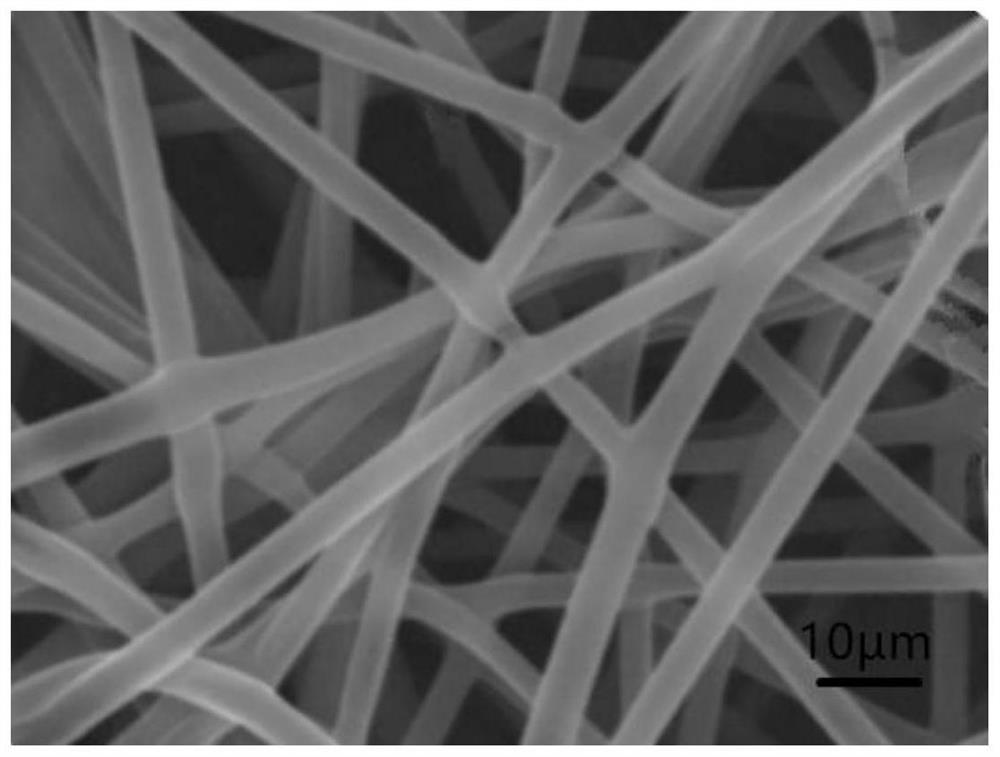

Image

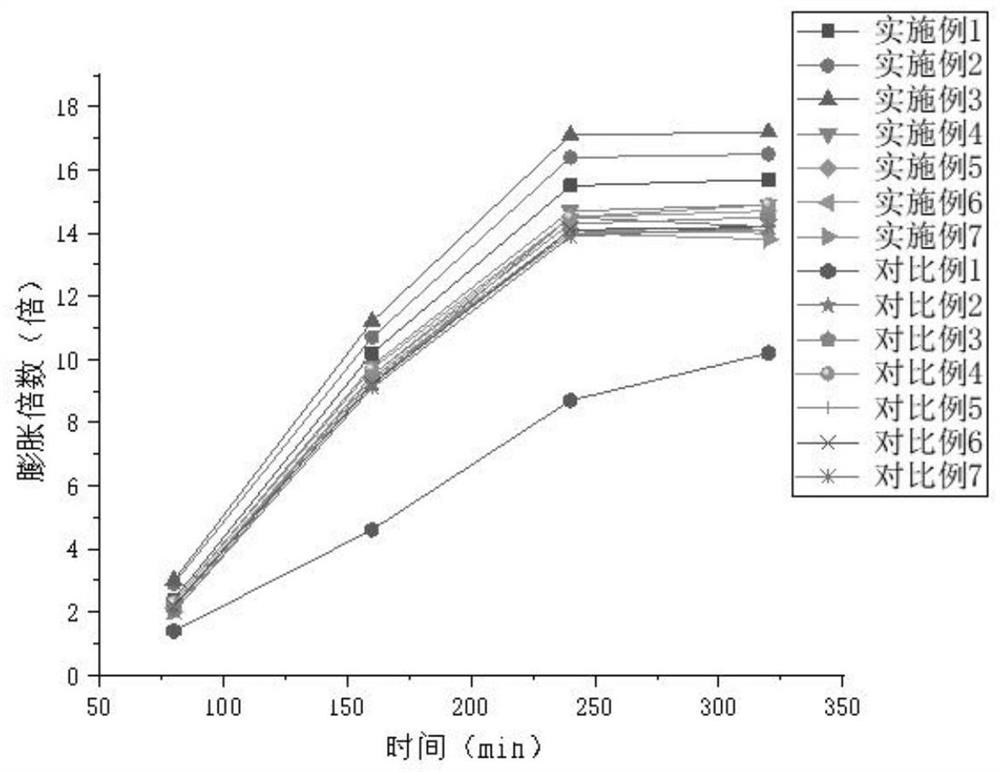

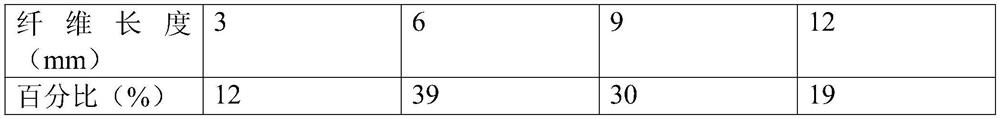

Examples

Embodiment 1

[0041] The present embodiment provides a preparation method of a water-soluble fracturing temporary plugging agent, which specifically includes the following steps:

[0042] Preparation of S1.P(AM-NVP-AMPS)@PLGA composite particles: 2 parts by weight of acrylamide, 1 part by weight of N-vinylpyrrolidone, 3 parts by weight of 2-acrylamido-2-methylpropanesulfonic acid and 30 parts by weight of PLGA was dissolved in water, adjusted the pH of the solution to 7, stirred and mixed evenly, heated to 50°C, and fed with N 2 , adding 10 parts by weight of an aqueous solution containing 0.01 parts by weight of an initiator, reacting for 5h, filtering, washing, drying, and pulverizing to obtain P(AM-NVP-AMPS)@PLGA composite particles; the initiator is sodium persulfate and sodium persulfate The compound mixture of sodium bisulfate, the mass ratio is 3:1;

[0043] S2. Preparation of polydopamine-modified P(AM-NVP-AMPS)@PLGA composite particles: add 100 parts by weight of the P(AM-NVP-AMPS...

Embodiment 2

[0047] The present embodiment provides a preparation method of a water-soluble fracturing temporary plugging agent, which specifically includes the following steps:

[0048] Preparation of S1.P(AM-NVP-AMPS)@PLGA composite particles: 5 parts by weight of acrylamide, 3 parts by weight of N-vinylpyrrolidone, 5 parts by weight of 2-acrylamido-2-methylpropanesulfonic acid and 30 parts by weight of PLGA was dissolved in water, adjusted the pH of the solution to 7.8, stirred and mixed evenly, heated to 70 ° C, passed Ar gas, added 10 parts by weight of an aqueous solution containing 0.1 part by weight of an initiator, reacted for 7 hours, filtered, washed, and dried , pulverized to obtain P(AM-NVP-AMPS)@PLGA composite particles; the initiator is a composite mixture of sodium persulfate and sodium bisulfite, and the mass ratio is 5:1;

[0049] S2. Preparation of polydopamine-modified P(AM-NVP-AMPS)@PLGA composite particles: add 100 parts by weight of the P(AM-NVP-AMPS)@PLGA composite ...

Embodiment 3

[0052] The present embodiment provides a preparation method of a water-soluble fracturing temporary plugging agent, which specifically includes the following steps:

[0053] Preparation of S1.P(AM-NVP-AMPS)@PLGA composite particles: 3.5 parts by weight of acrylamide, 2 parts by weight of N-vinylpyrrolidone, 4 parts by weight of 2-acrylamido-2-methylpropanesulfonic acid and 30 parts by weight of PLGA was dissolved in water, adjusted the pH of the solution to 7.4, stirred and mixed evenly, heated to 60°C, and fed with N 2 , adding 10 parts by weight of an aqueous solution containing 0.05 parts by weight of an initiator, reacting for 6 h, filtering, washing, drying, and pulverizing to obtain P(AM-NVP-AMPS)@PLGA composite particles; the initiator is sodium persulfate and sodium persulfate The compound mixture of sodium bisulfate, the mass ratio is 4:1;

[0054] S2. Preparation of polydopamine-modified P(AM-NVP-AMPS)@PLGA composite particles: add 100 parts by weight of the P(AM-NV...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com