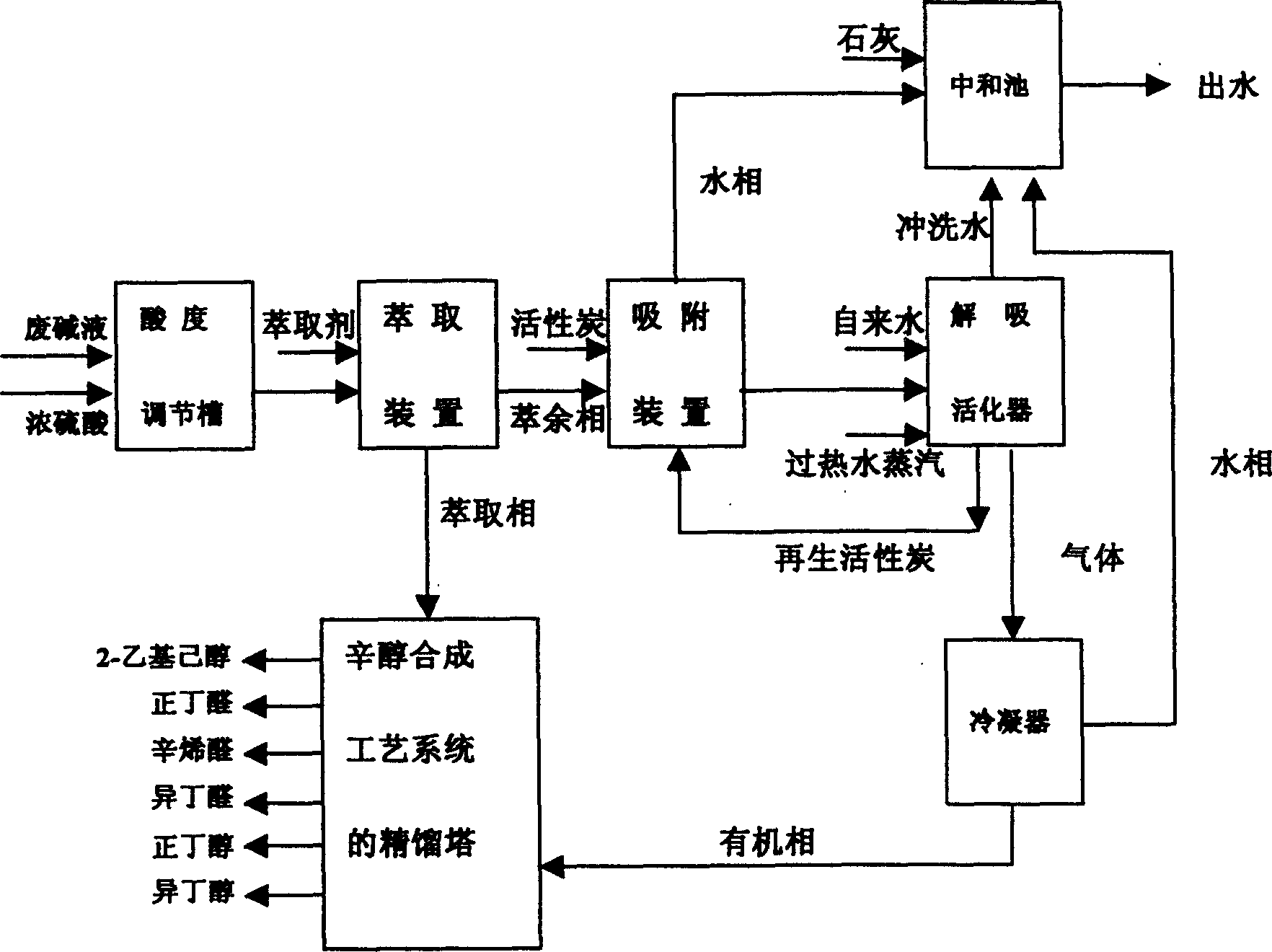

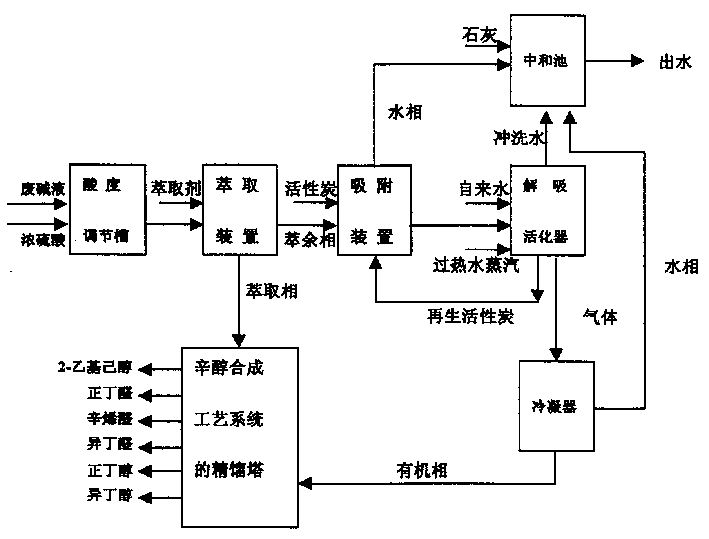

Treatment process for two stage recycling waste alkali liquid drained off by process system of synthesizing octanol

A synthesis process and recycling technology, applied in the field of environmental technology and chemical separation, can solve the problems of low removal efficiency, no instructions on how to recover organic components, etc., to save equipment investment and operating costs, overcome the increase of regeneration boiling point, and control significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] For temperature 50°C and COD Cr Concentration is the waste alkali liquor of 42.2g / L to carry out treatment. The weight ratio of concentrated sulfuric acid (93%) and spent lye is that both are added in the acidity adjustment tank in the ratio of 1: 19, the pH value of waste water is 1.5, waste water and extraction agent (2-ethylhexanol) are mixed with The countercurrent way is introduced into the pulse packed tower, the waste water is introduced from the top of the extraction tower as a continuous phase, and the extractant is introduced from the bottom of the extraction tower as a dispersed phase, and the amount of the extractant is 1 / 8 of the volume of the spent lye. COD of the raffinate phase of the extraction operation Cr The concentration is 4.9g / L, COD Cr The removal rate was 88.4%. Pass compressed air in the adsorption tank to stir the raffinate phase with granular activated carbon with an amount of 50g / L for 1 hour and then let it stand for 20 minutes to absorb...

Embodiment 2~4

[0024] Treat the waste lye with a temperature of 50°C. The weight ratio of concentrated sulfuric acid (93%) and waste lye is 1:62, the two are added in the acidity adjustment tank, the pH value of the waste water is 2.86, and the extraction agent 2-ethylhexanol and the waste water are countercurrently Import into the extraction tower equipped with secondary extraction units, add extractant to each extraction unit according to a certain volume ratio, and the mixed solution is vigorously stirred in the mixer of each extraction unit for 2 minutes, and then enters the separator After standing for 10 minutes, the extract phase and the raffinate phase were separated, and the raffinate phase and the granular activated carbon with an amount of 50g / L were stirred in the adsorption tank for 1 hour and then allowed to stand for 2 hours. See Table 1 for the treatment effects under the action.

[0025]

Embodiment 5~7

[0027] The weight ratio of concentrated sulfuric acid (93%) and waste lye is that the two are added in the acidity adjustment tank at a ratio of 1: 62, and the pH value of the waste water is 2.86, and then the extractant 2-ethylhexanol and the waste water are countercurrently The method is introduced into the extraction tower equipped with a secondary extraction unit, and the extraction agent is added to each extraction unit according to the ratio of the volume ratio of waste caustic soda to extraction agent of 4:1, and the mixed solution is in the mixer of each extraction unit After 2 minutes of vigorous stirring, enter the separator and let it stand for 10 minutes to separate the extract phase and raffinate phase, and pass compressed air in the adsorption tank to stir the raffinate phase with 50g / L granular activated carbon for 1 hour. After standing still for 2 hours, the tests were carried out under the conditions of wastewater temperatures of 45° C., 52° C. and 60° C. resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com