Process for producing pigment dispersing resin of positive ion electroplating paint

A pigment dispersion and cationic technology, applied in electrophoretic coatings, pigment pastes, epoxy resin coatings, etc., can solve problems such as poor appearance and low fluidity of electroplating coating films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

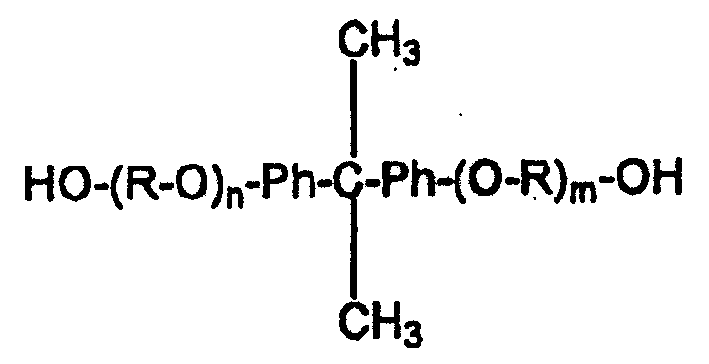

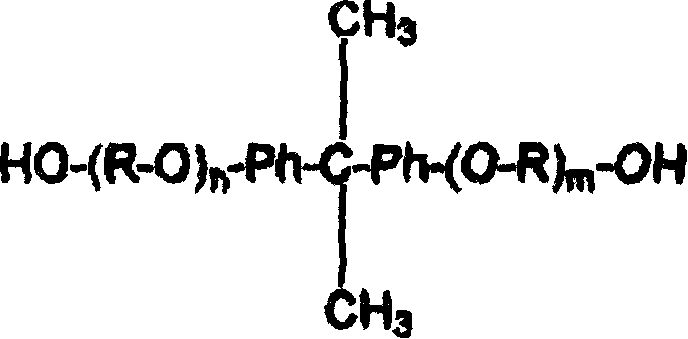

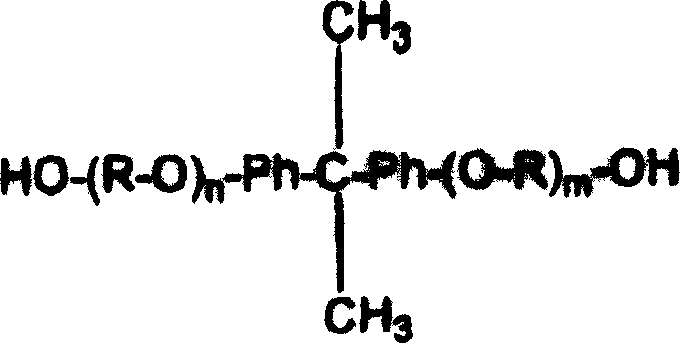

Image

Examples

manufacture example 1

[0060] Manufacturing example 1 (production of amine-modified epoxy resin)

[0061] 92 parts of 2,4- / 2,6-toluene diisocyanate (weight ratio=8 / 2), 95 parts of methyl isobutyl ketone (MIBK) and 0.5 parts of dibutyltin dilaurate were introduced into the equipment equipped with Stirrer, condenser, nitrogen pipe, thermometer and dropping funnel in the flask. 21 parts of methanol were added while the mixture was stirring. The reaction was started at room temperature and heated to 60°C, then the reaction was continued for 30 minutes, and 57 parts of ethylene glycol mono-2-ethylhexyl ether were added dropwise through the dropping funnel. To this content was added 42 parts of bisphenol-5 mole propylene oxide adduct A (PO 5 ) (BP-5P, supplied by Sanyo Kasei). The reaction proceeds initially at around 60°C to 65°C and continues until the IR spectrum shows the disappearance of the isocyanate group-based absorption.

[0062] To the above mixture, 365 parts of a bisphenol A type epoxy res...

manufacture example 2

[0064] Production Example 2 (Synthesis of Block Polyisocyanate Curing Agent)

[0065] 1,723 parts of 2,5- and 2,6-bis(isocyanatomethyl)-bicyclo[2,2,1]heptane (103 isocyanate equivalents, supplied by Mitsui Toatsu), 333 parts of MIBK and 0.01 part of dilauryl Dibutyltin dibutyltin was charged in the same flask as in Production Example 1. The resulting mixture was heated to 70° C. and dissolved uniformly, and then 610 parts of methyl ethyl ketoxime was added dropwise over 2 hours. After all the ketoxime has been added dropwise, the reaction continues until the IR spectrum shows that the absorption based on the isocyanate group disappears when the reaction temperature is maintained at 70° C., resulting in a methyl ethyl ketoxime blocked polyisocyanate curing agent (80% resin solids) ).

manufacture example 3

[0066] Production Example 3 (Production of Pigment Dispersion Resin Varnish Containing Quaternary Ammonium Group)

[0067] 87.2 parts of dimethylethanolamine, 117.6 parts of 75% lactic acid aqueous solution and 39.2 parts of ethylene glycol monobutyl ether were sequentially added to a suitable reaction vessel, and the batch was stirred at 65° C. for 0.5 hour to obtain quaternary ammonium agent.

[0068]Add 710.0 parts of Epon 829 (bisphenol A epoxy resin, supplied by Shell Chemical Co., 193-203 epoxy equivalent weight) and 289.6 parts of bisphenol A into a suitable reaction vessel at the same time, and heat to 150-160 ° C under nitrogen In between, the reaction mixture was reacted at 150-160° C. for about 1 hour, then cooled to 120° C., and 498.8 parts of 2-ethylhexanol semi-block IPDI (MIBK solution) prepared in Production Example 3 was added.

[0069] The reaction mixture was kept at 110-120° C. for about 1 hour, and then the polyalkylene oxide compound (BEP-60, supplied by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com