Preparation method of metallic nano powder

A metal nano-powder, metal technology, applied in the field of metal nano-powder preparation, to achieve the effects of easy dispersion, reduced post-processing loss, and easy control of particle diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

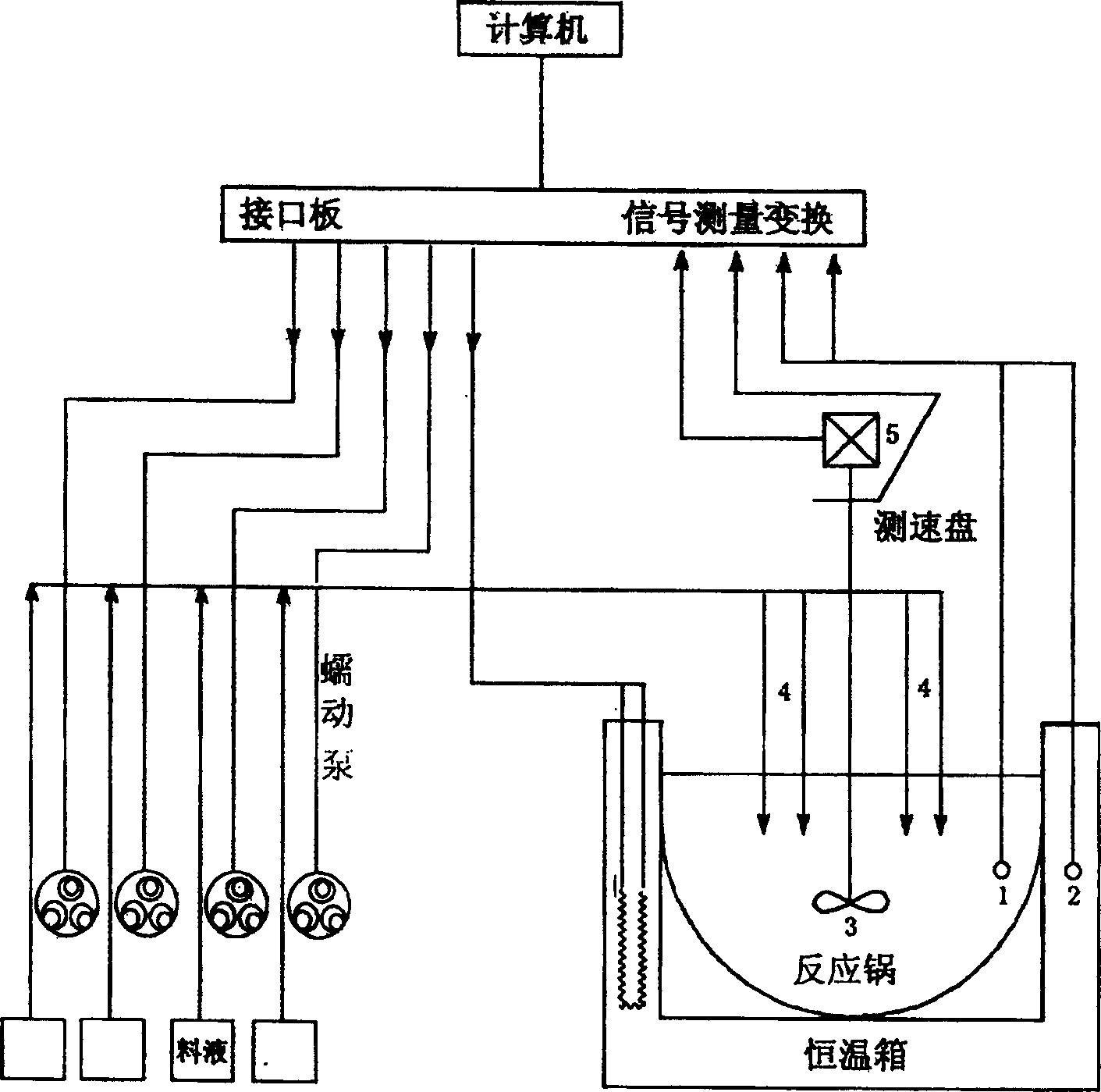

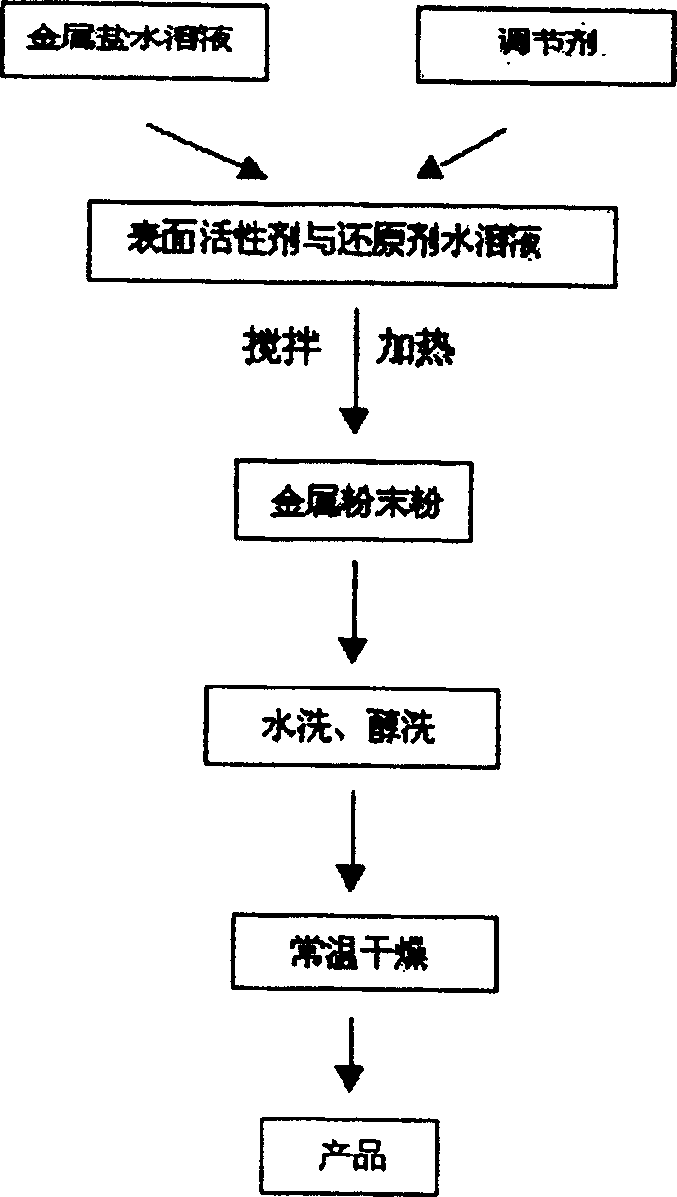

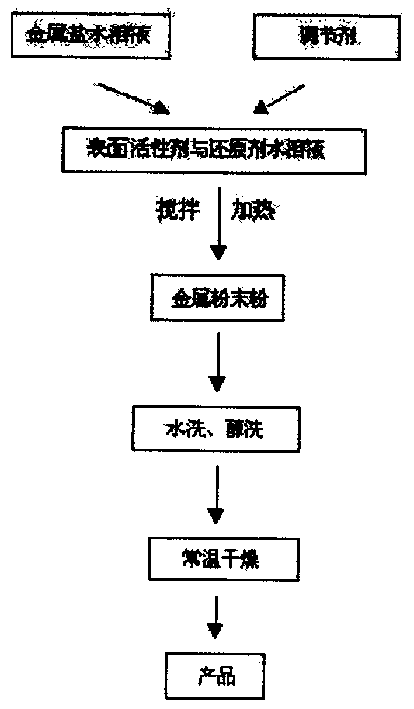

Method used

Image

Examples

Embodiment 1

[0035] Take 55 parts by weight of sodium hypophosphite, 5 parts by weight of gelatin, and 1.5 parts by weight of concentrated sulfuric acid, and dissolve them in 500 parts by weight of distilled water to obtain feed solution A.

[0036] Take parts by weight as 100 parts of CuSO 4 , be dissolved in 500 parts by weight of distilled water to obtain feed liquid B.

[0037] 50 parts by weight of sodium hypophosphite and 0.26 parts by weight of concentrated sulfuric acid were dissolved in 500 parts by weight of distilled water to obtain feed liquid C.

[0038] Add the material liquid A as the bottom liquid into the reaction kettle of the double-injection instrument, control the temperature of the reaction kettle at 80±5°C, and add the material liquid B and C into the reaction kettle at the same time and at a uniform speed under continuous stirring at 500 rpm middle. Adding time is controlled in 6~7 minutes. Constant temperature, stirring reaction for 1 hour.

[0039] Pour out th...

Embodiment 2

[0041] Take 56 parts by weight of sodium borohydride and 10 parts by weight of surfactant sodium butanedioctyl sulfonate (AOT), dissolve them in 500 parts by weight of distilled water to obtain feed liquid A.

[0042] Take parts by weight as 100 parts of AgNO 3 , be dissolved in 500 parts by weight of distilled water to obtain feed liquid B.

[0043] Take 2 parts by weight of NaOH and dissolve it in 500 parts by weight of distilled water to obtain feed liquid C.

[0044] Add material liquid A as the bottom liquid into the reaction kettle made of stainless steel of the double-injector, control the temperature of the reaction kettle at 30±5°C, and keep stirring at 500 rpm, and simultaneously and uniformly feed the material liquids B and C Added to the reaction kettle. Adding time is controlled in 6~7 minutes. After the addition, keep the temperature and stir the reaction for 30 minutes.

[0045]Pour out the residual clear liquid after the reaction, wash and soak with distill...

Embodiment 3

[0047] Take 80 parts by weight of glucose and 10 parts by weight of surfactant sodium hexadecylsulfonate, dissolve them in 500 parts by weight of distilled water to obtain feed liquid A.

[0048] Take parts by weight as 100 parts of AgNO 3 , be dissolved in 500 parts by weight of distilled water to obtain feed liquid B.

[0049] Take 32 parts by weight of NaOH and dissolve it in 500 parts by weight of distilled water to obtain feed liquid C.

[0050] Add the material liquid A as the bottom liquid into the reaction kettle of the double-injector, control the temperature of the reaction kettle at 60±5°C, and add the material liquid B and C into the reaction kettle at the same time and at a uniform speed under continuous stirring at 200 rpm middle. Adding time is controlled in 6~7 minutes. After the addition, keep the temperature and stir the reaction for 20 minutes.

[0051] Pour out the residual clear liquid after the reaction, wash and soak with distilled water for 5 times,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com