Wheel type hydraulic drifting machine

A well drilling machine and hydraulic technology, applied in wellbore/well parts, earthwork drilling and production, etc., can solve the problems of transmission system and main drawworks drum failure, high maintenance cost, low installed power, etc., and shorten the operation preparation time , Braking is safe and reliable, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

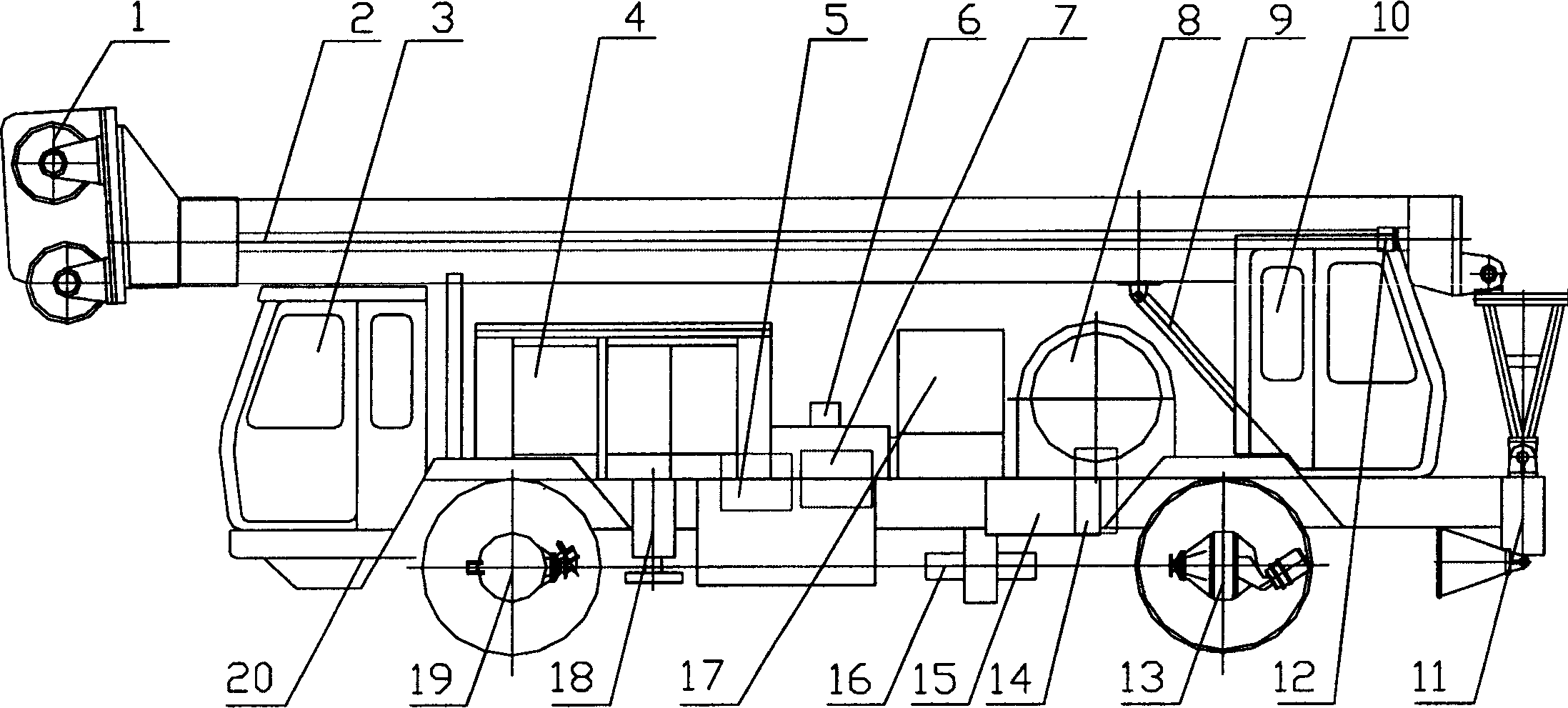

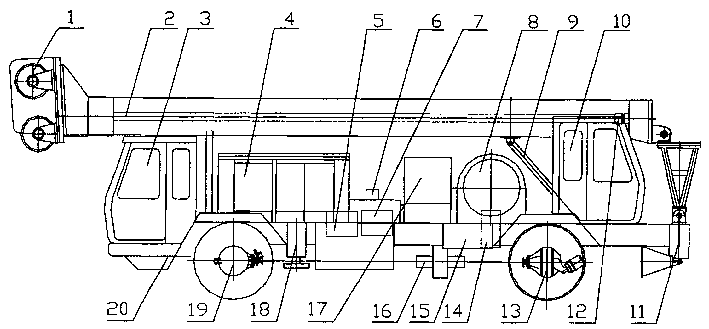

[0007] Below in conjunction with accompanying drawing, the present invention is described in further detail: referring to accompanying drawing, wheeled hydraulic well drilling machine is made up of engine 4, driver's cab 3, operating room 10, hydraulic oil tank 17 and operating system, walking part and operation part etc., The walking part has a chassis 20, a front drive axle 19 and a rear drive axle 13; the working part has a crane 1, a derrick 2 and a hydraulic lifting control system, and the derrick 2 is lifted by a hydraulic control cylinder, which is composed of a hydraulic cylinder 12 and a lifting control system. Liter oil cylinder 9 forms. The hydraulic transmission system transmits the power of the engine 4 to the gearbox 16, and the gearbox 16 transmits the power to the walking part and the working power transmission mechanism respectively. The hydraulic transmission system consists of a hydraulic pump 5 , a main valve block 6 , and a hydraulic motor 7 . The engine 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com