Nano gold/SO2 mesoporous composite body and its preparing method

A technology of silica and composites, applied in the field of nanocomposite materials and their preparation, can solve the problems of pollution, inability to realize the adjustment of optical characteristics, high cost, etc., and achieve the effect of simple process, low cost and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

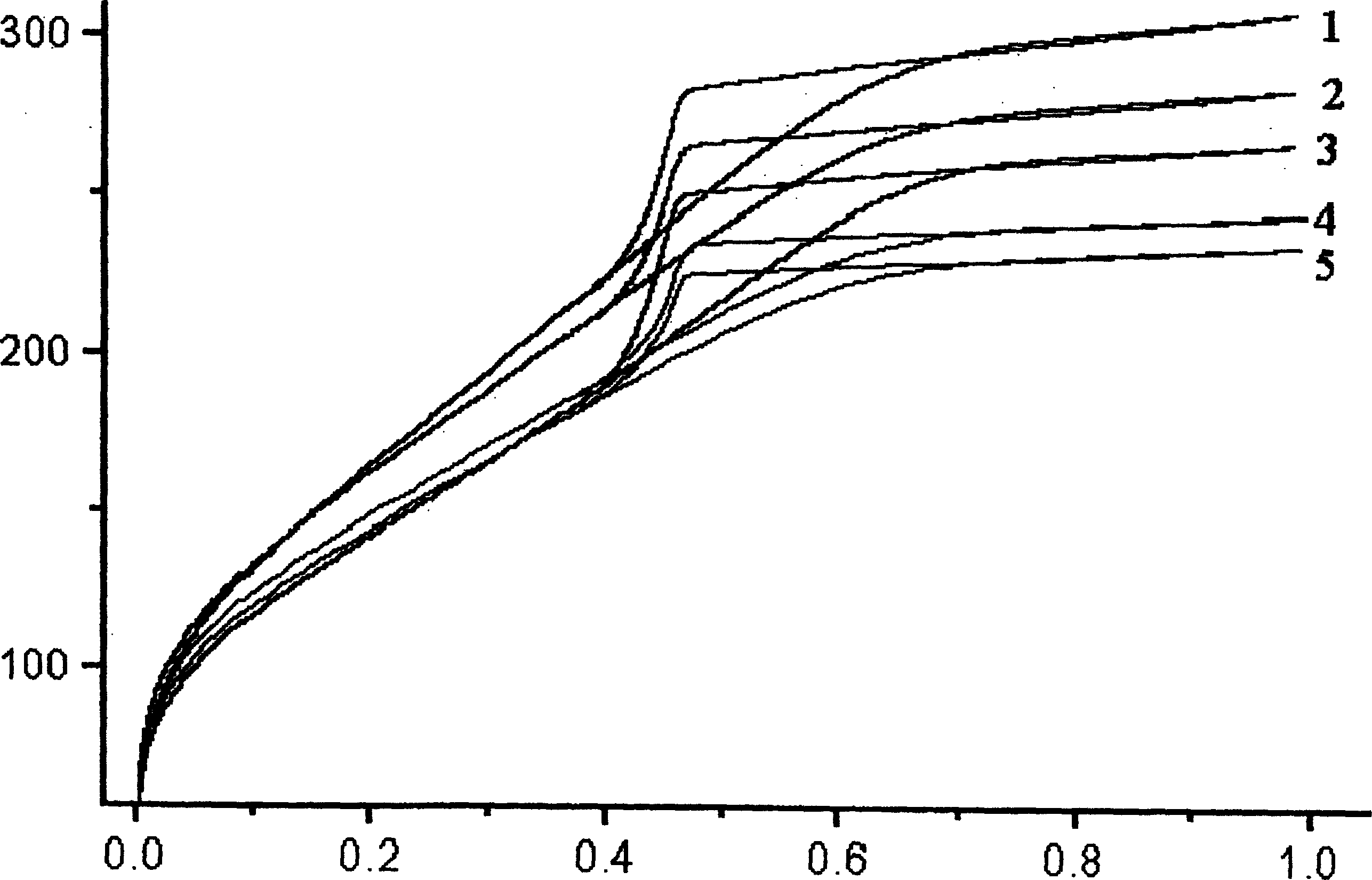

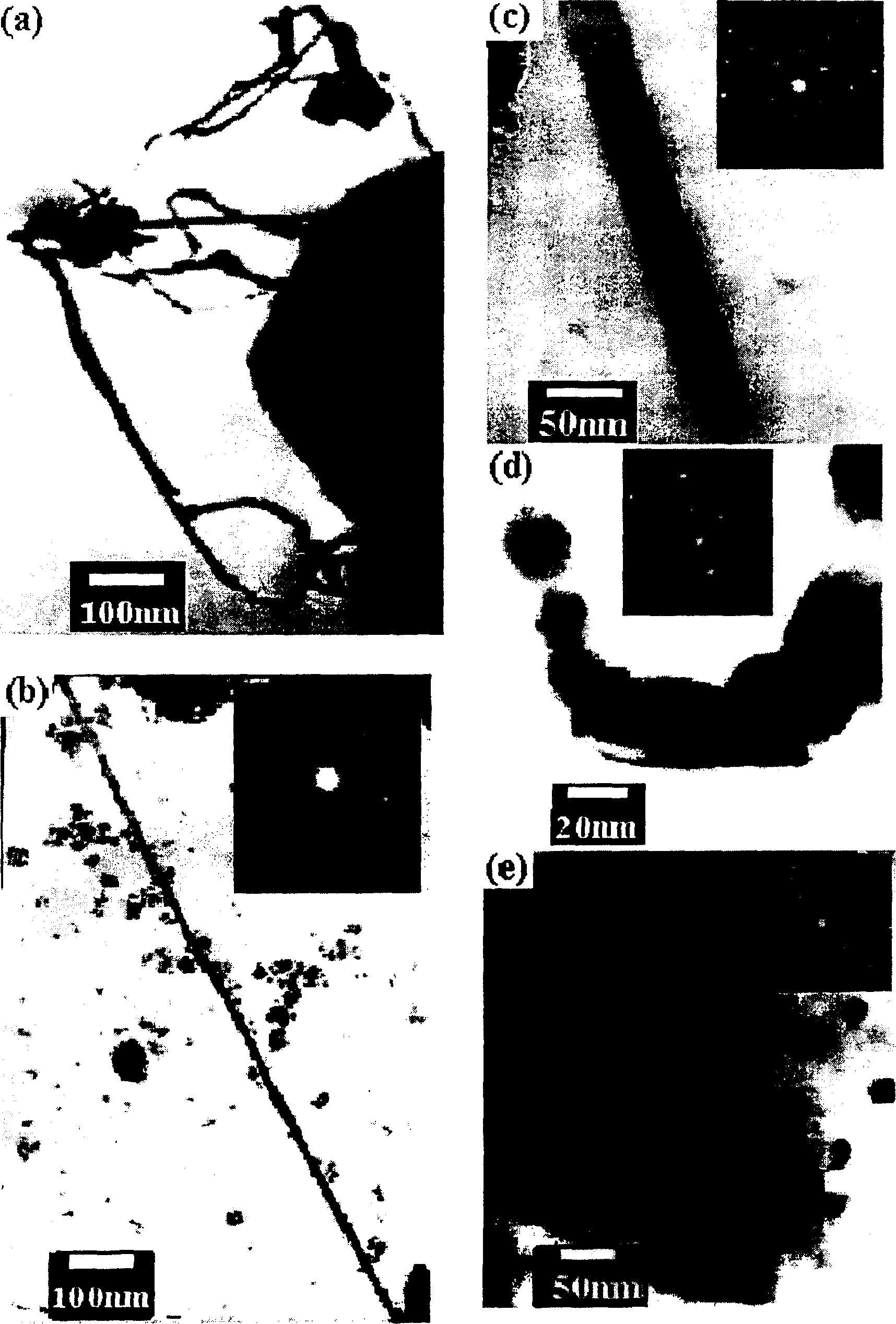

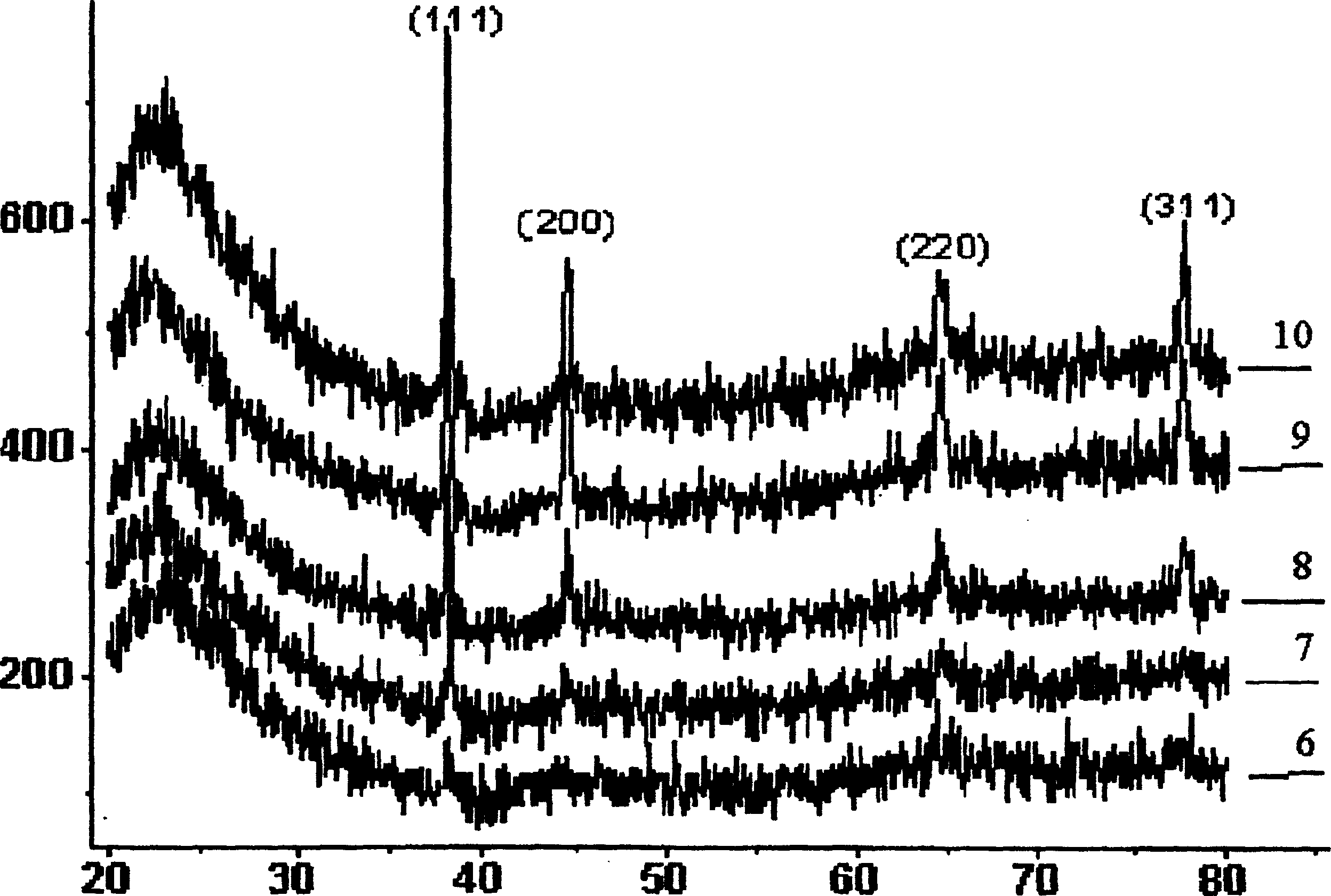

[0017] Place the prepared flaky silica mesoporous solid in a tetrachloroauric acid solution with a concentration of 5 mmol and soak for 12 days, then take out the soaked mesoporous solid, wash it with deionized water, and dry it at 70°C 14 hours, and finally it was annealed at 200°C for 2 hours to obtain figure 1 Curve 1 in figure 2 Figure (a) in and image 3 The nano-gold / silica mesoporous composite shown in the curve 6, its light absorption spectrum is as Figure 4 Curve 11.

Embodiment 2

[0019] Put the above-mentioned mesoporous solid in a tetrachloroauric acid solution with a concentration of 8 mmol and soak for 12 days, then wash the taken-out mesoporous solid with distilled water and dry it at 80°C for 15 hours, and finally remove it from 200°C in steps The temperature is raised from 50°C to 350°C, and kept at each temperature point for 2.5 hours to obtain the following figure 1 Curve 2 in figure 2 Figure (b) in and image 3 The nano-gold / silica mesoporous composite shown in the curve 7, its light absorption spectrum is as Figure 4 Curve 12.

Embodiment 3

[0021] The above-mentioned mesoporous solid was soaked in a tetrachloroauric acid solution with a concentration of 10 mmoles for 14 days, then the taken-out mesoporous solid was washed with deionized water and dried at 85°C for 15 hours, and finally it was removed from 200°C Raise the temperature from 75°C to 500°C with a step diameter of 75°C, and keep it warm at each temperature point for 3 hours (it can also be annealed at 500°C for 2 hours), and the following figure 1 Curve 3 in figure 2 Figure (c) in and image 3 The nano-gold / silica mesoporous composite shown in the curve 8, its light absorption spectrum is as follows Figure 4 Curve 13.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com