Micromechanical optical switch made of metal material

An optical switch and micro-mechanical technology, applied in optics, light guides, optical components, etc., can solve the problems of limited size of micro-mirrors, low reflection coefficient and high difficulty, and achieve the effect of simple unit structure, good scalability and simple control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

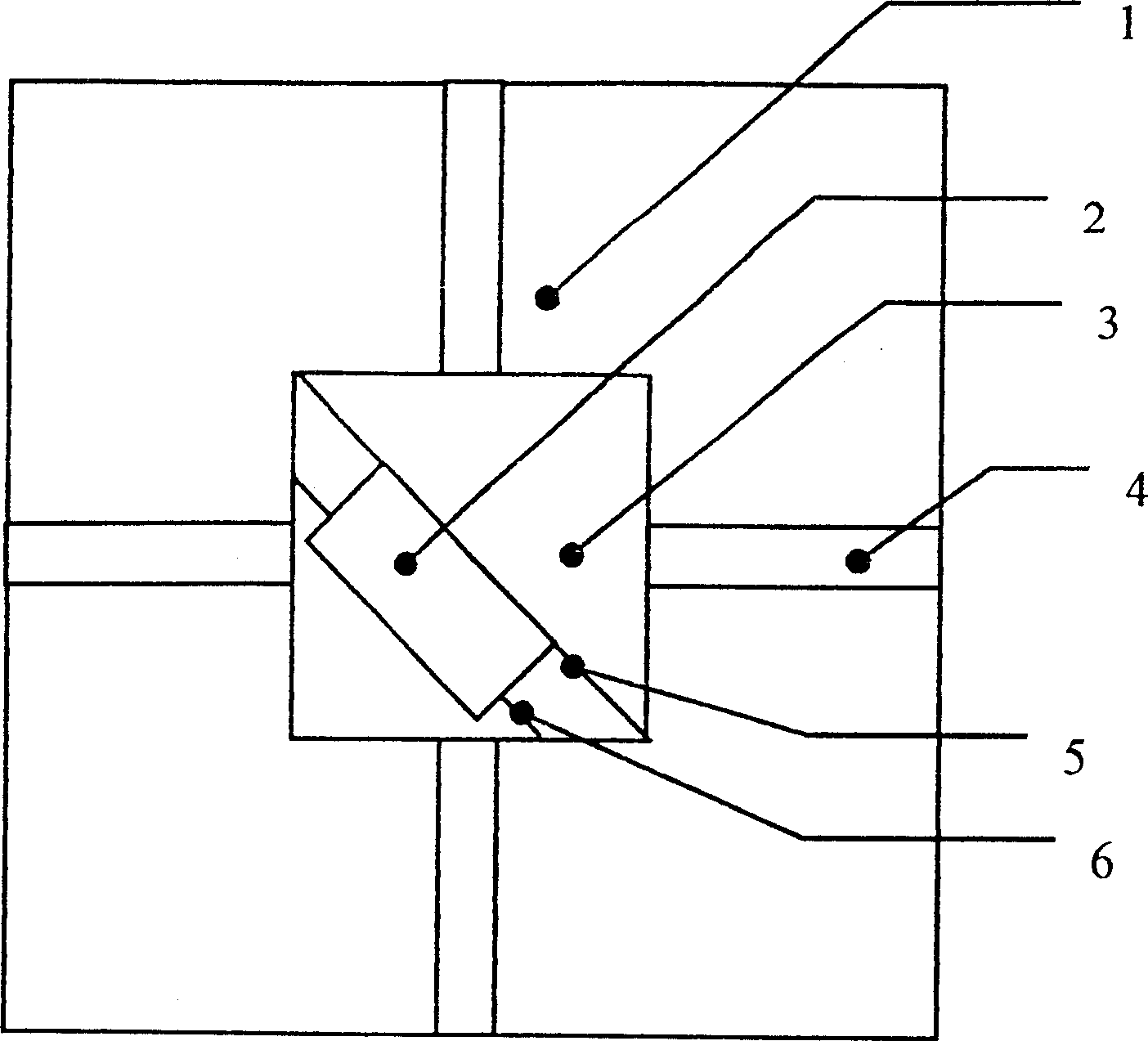

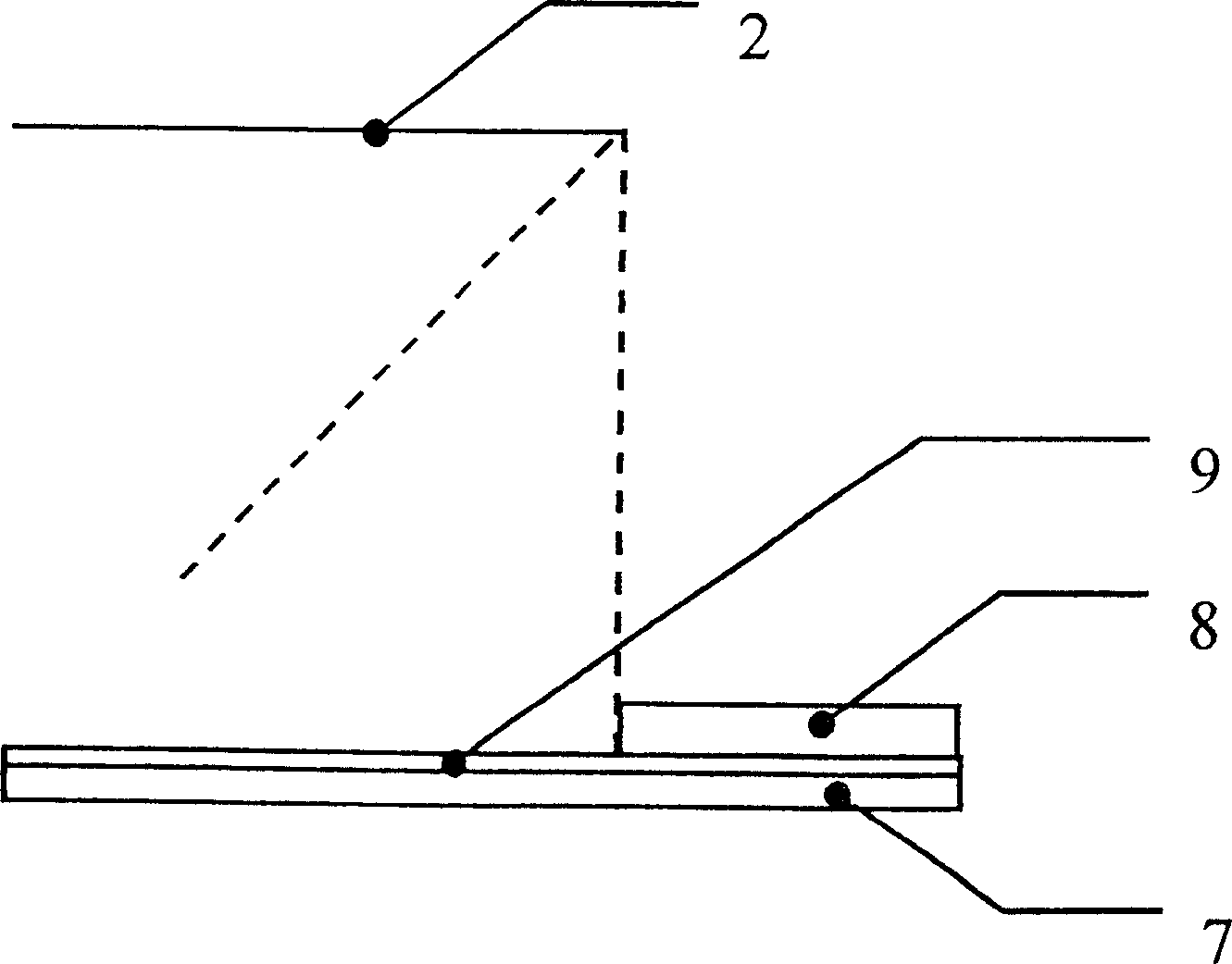

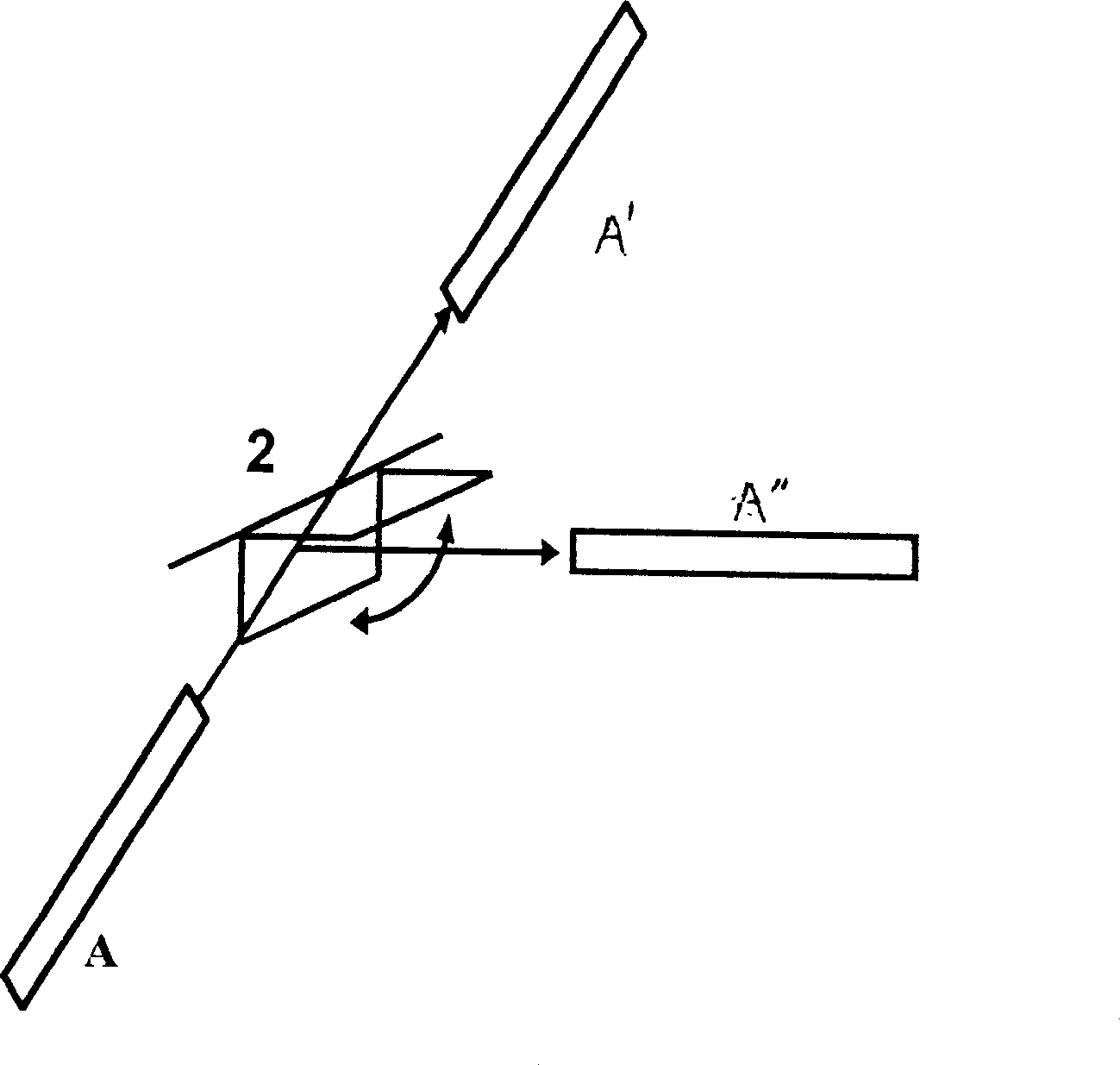

[0026] see figure 1 and figure 2 , the optical switch is composed as follows: a substrate 1 formed by a silicon wafer, a micromirror 2, a through hole 3, a V-shaped groove 4, a double-sided cantilever beam 5, a temporary support beam 6, a lower electrode 7, a micromirror stop structure 8 and The anti-breakdown layer 9 consists of several parts. The micromirror 2 is a twistable horizontal structure, made of various metal alloy materials, and also serves as an upper electrode. Directly below the micromirror 2 is a through hole 3 whose depth is slightly greater than the length of the micromirror. The double-sided cantilever arm 5 is supported on both sides of the micromirror 2, and is a rectangular cantilever beam, which is formed by the same metal mask as the micromirror. The lower electrode 7 is formed by sputtering metal on the silicon chip at the lower part of the through hole 3, and together with the upper electrode formed by the micromirror 2, forms an electrostatically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com