Method for producing plate shape body and semiconductor device

A manufacturing method and technology of plate-like bodies, which are applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components and other directions, can solve problems such as warpage, strength reduction, complex process, etc., and achieve low sheet resistance, The effect of dense surface flatness and high connection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0098] Description of the first embodiment of the plate-shaped body

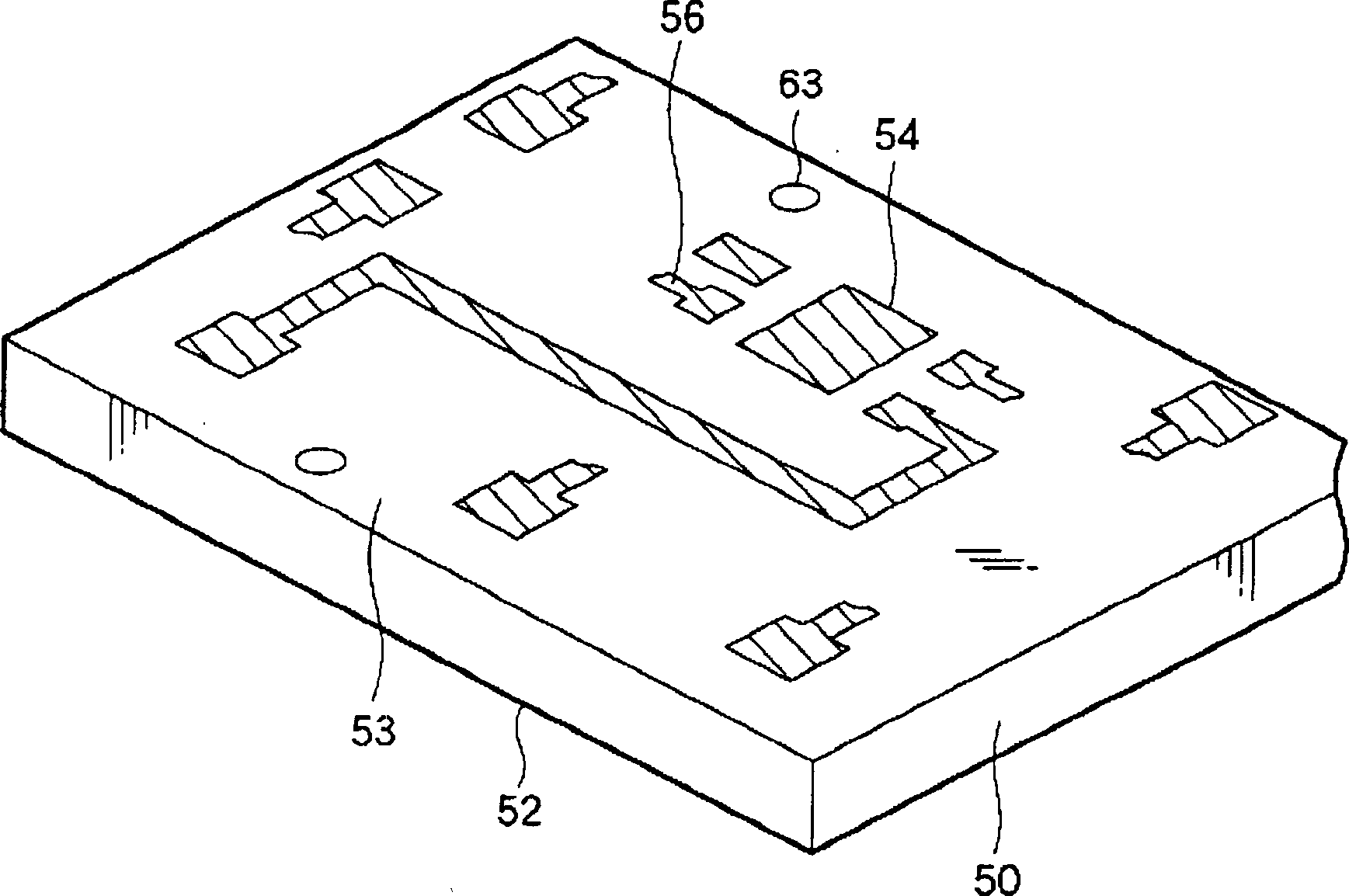

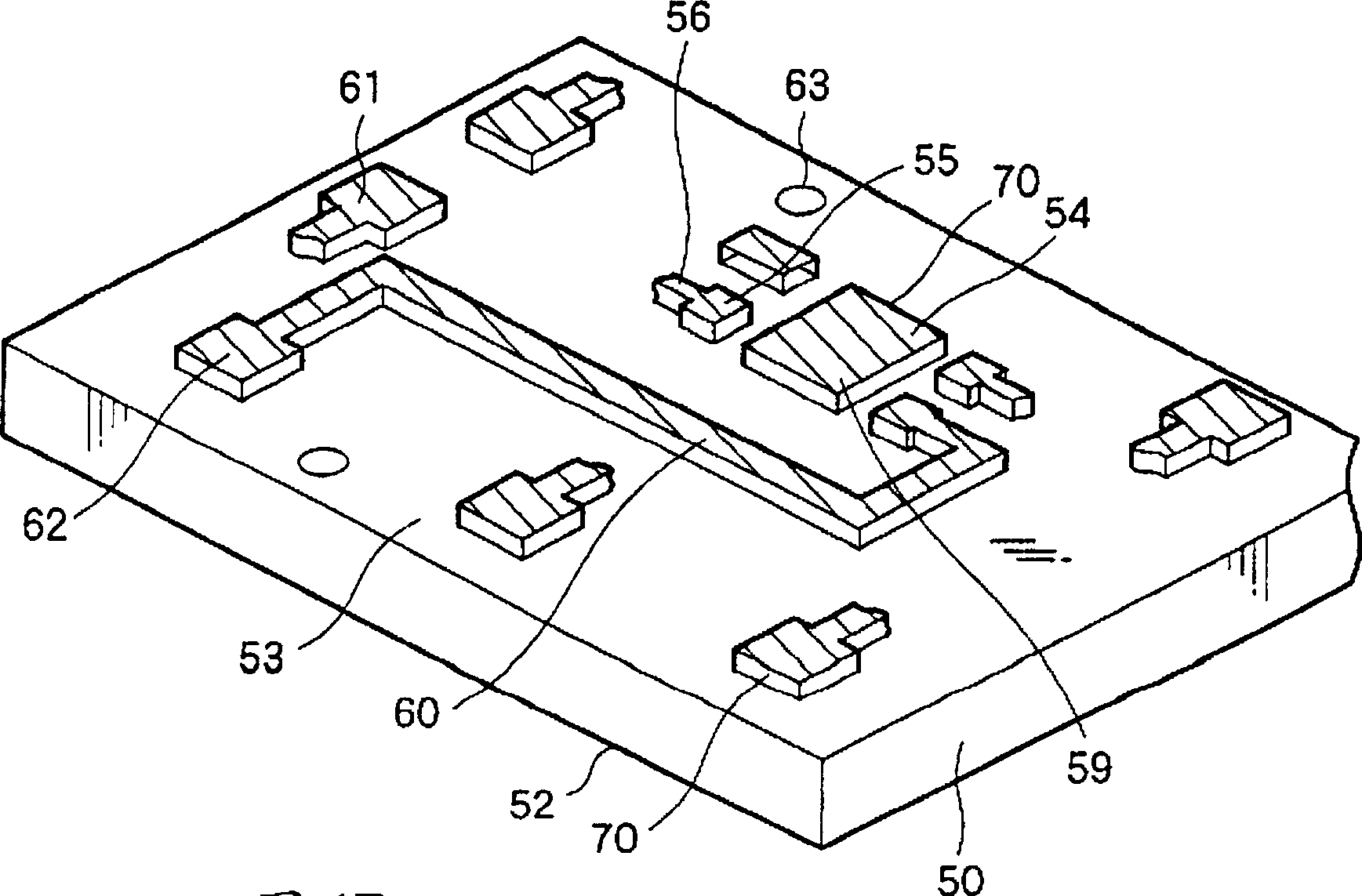

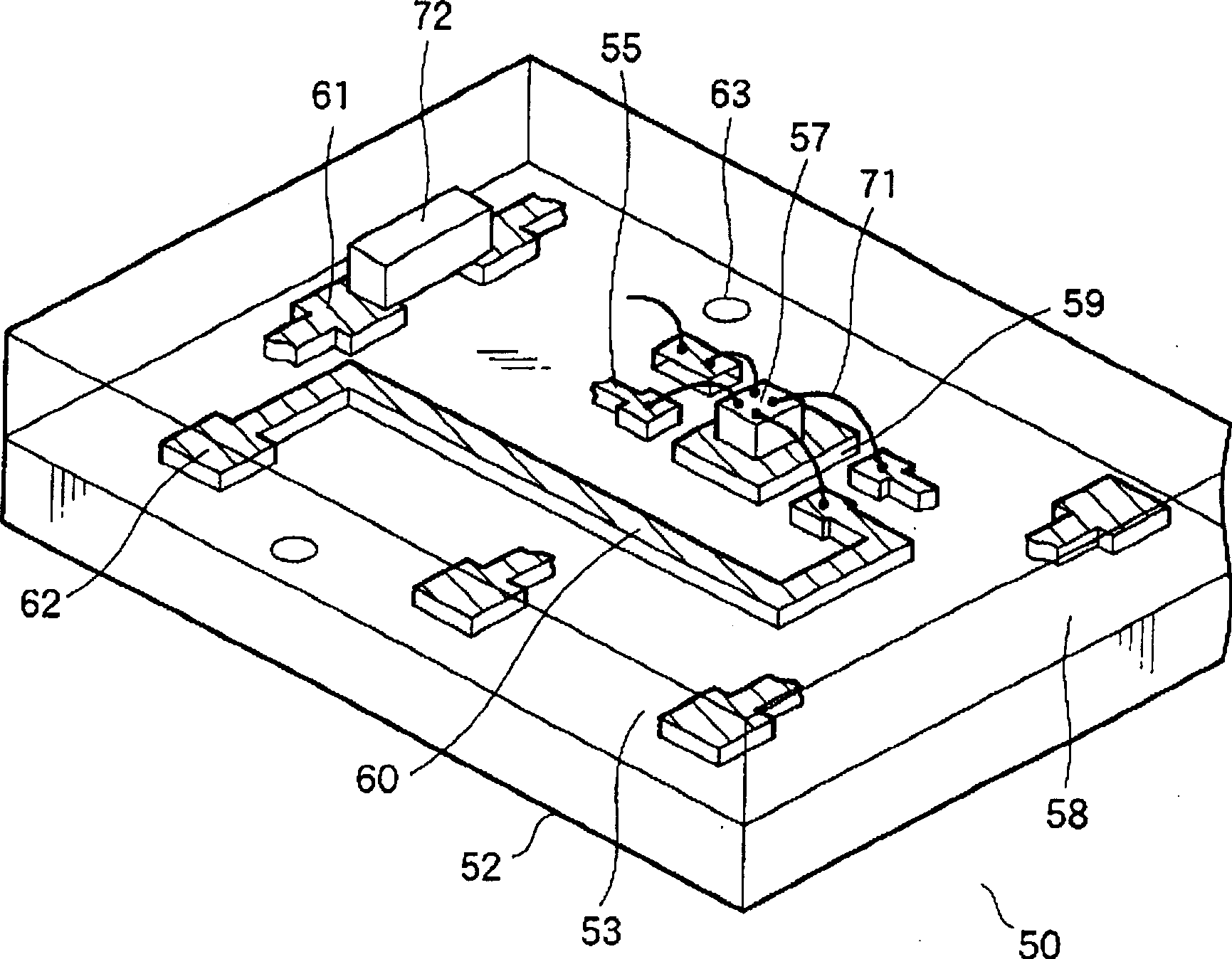

[0099] Figure 1A It is a plate-shaped body showing that a thinner package with better reliability during miniaturization can be realized than a conventional IC or a hybrid IC using a standard frame.

[0100] The plate-shaped body 50, such as Figure 1A The pattern of its conventional hybrid IC is formed by a conductive cover film 56 as shown.

[0101] That is, the plate-shaped body 50 has a first surface 52 formed of a flat surface, and a second surface 53 formed of a flat surface provided to face the first surface 52 .

[0102] On the second surface 53, a first conductive cover film 56 having substantially the same pattern as the plurality of first pads 55 provided on or near the semiconductor element mounting region 54 is formed.

[0103] The plate-shaped body 50 may be formed with an etching-resistant mask such as photoresist instead of the aforementioned conductive coating. At this time, at least the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com