Adhesive lining cloth coated with water-soluble resin and its making method

A technology of water-soluble resin and adhesive interlining, which is applied in the direction of film/sheet adhesives, adhesives, textiles and papermaking, etc. It can solve the problems of reducing the use value of shirts, not being scratched, and procrastinating for a long time. Improve the use value and eliminate the effect of foaming problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

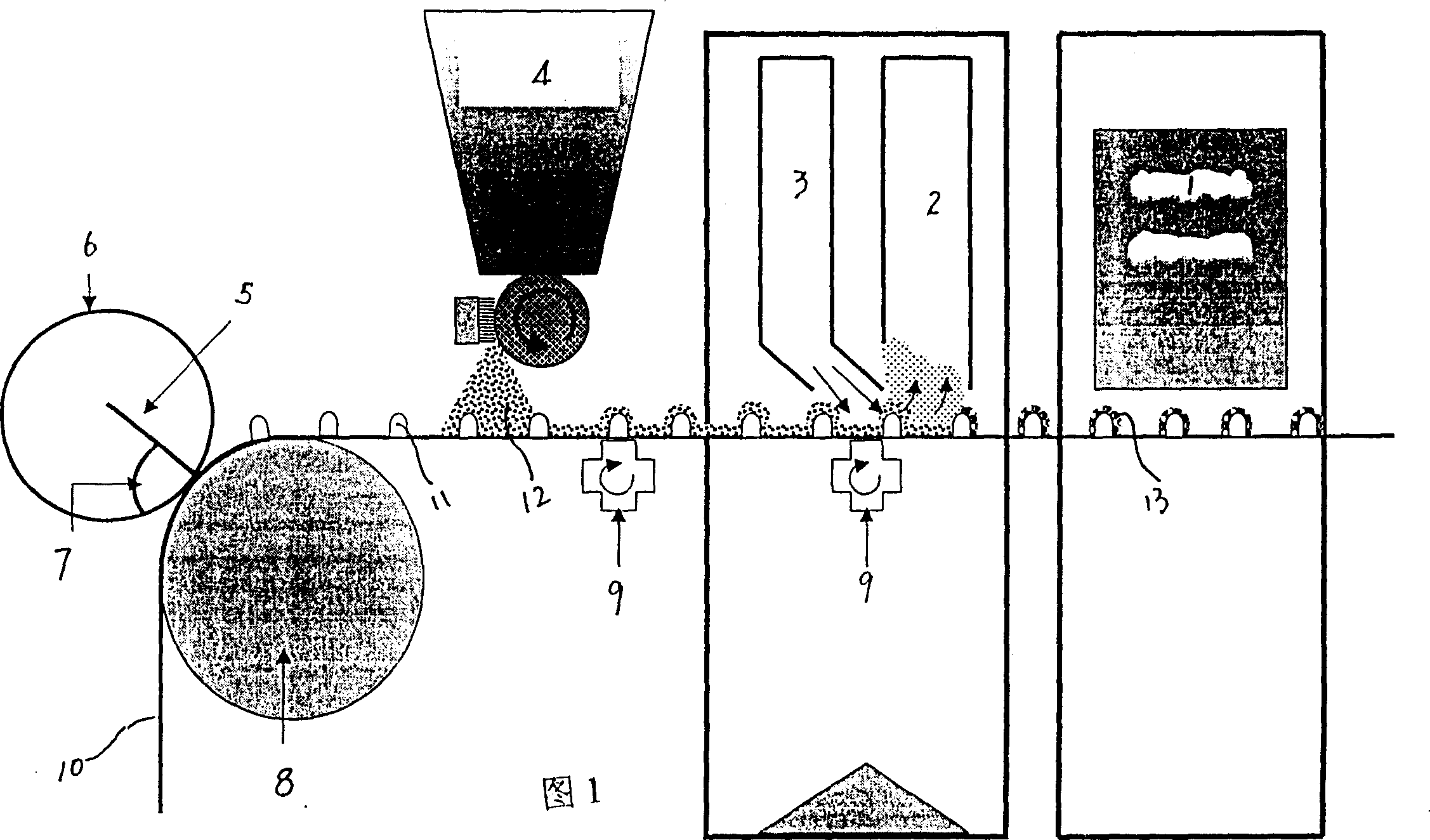

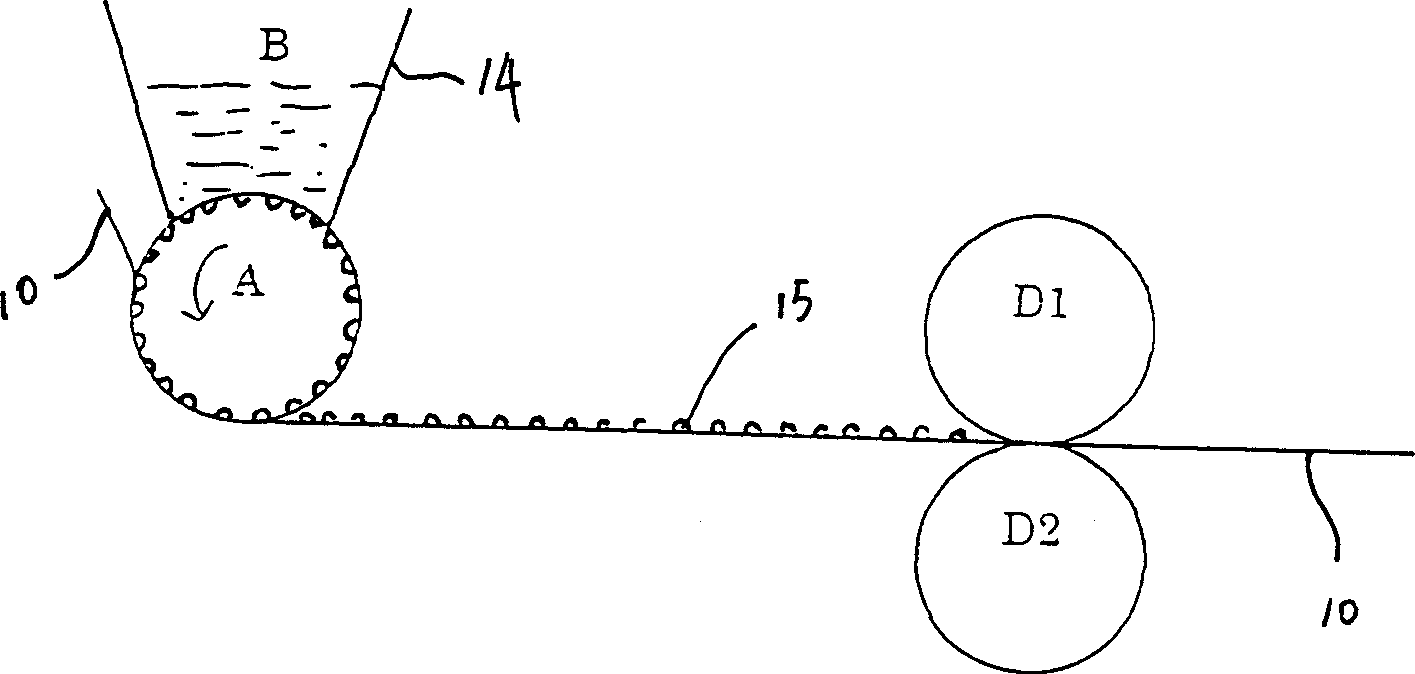

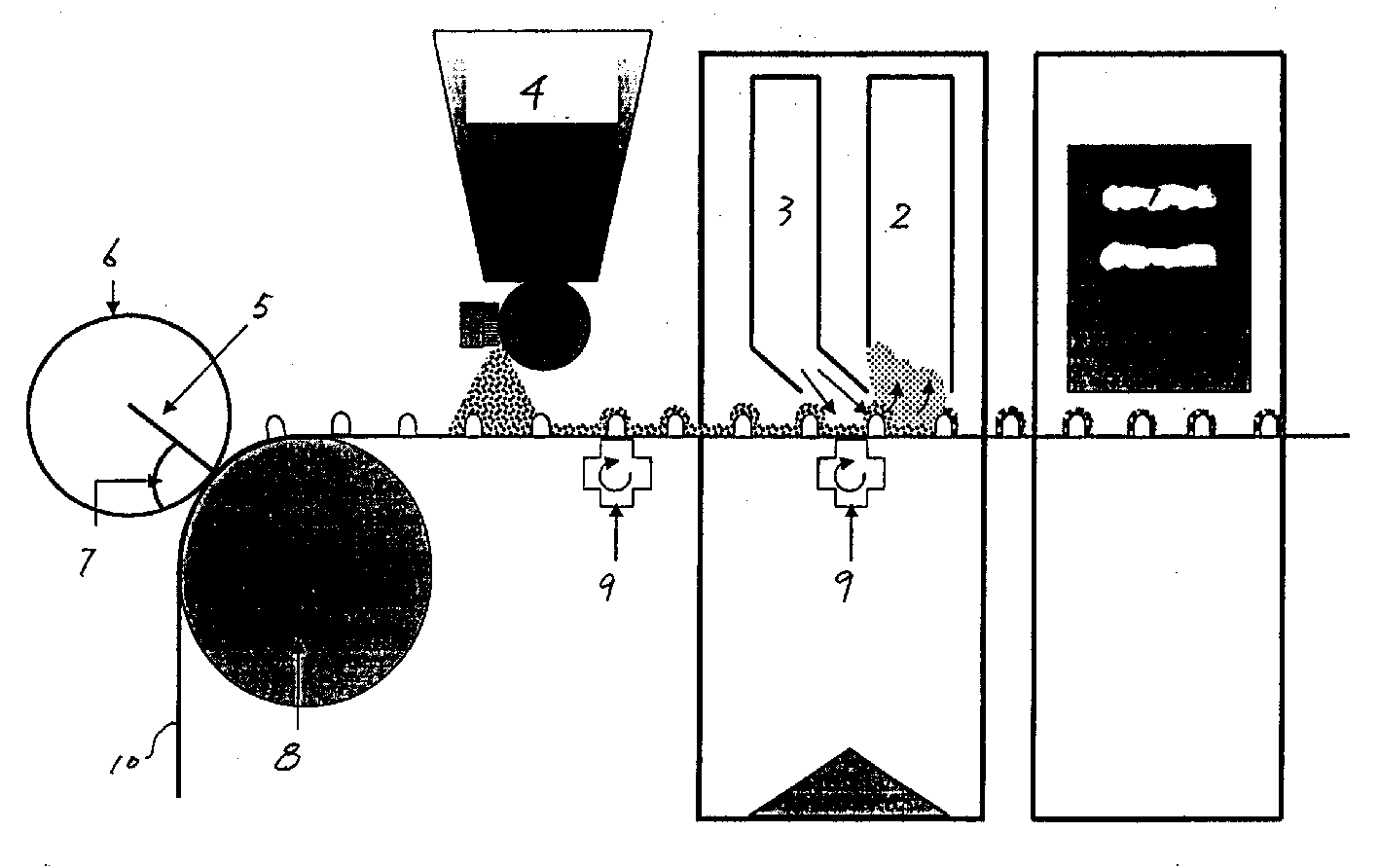

Method used

Image

Examples

Embodiment 1

[0046] The T / C 45S polyester-cotton fabric is produced through continuous refining, continuous pad dyeing, resin / waterproof co-bath finishing, and water-soluble PVA resin hot-melt transfer bonding.

[0047] 1. Raw material: T82111

[0048] 2. Refining:

[0049] The refining machine is a continuous refining machine - a heat setting machine.

[0050] The function of the continuous refiner is desizing, refining and bleaching.

[0051] Auxiliary ingredients: sodium hydroxide NaOH: 30g / l, hydrogen peroxide H2O2: 30g / l, metal ion chelating agent: 5g / l, refining detergent: 2.5g / l, desizing agent: 5g / l, hydrogen peroxide stabilizer: 5g / l, oxalic acid: 5g / l;

[0052] Reaction time: 45 minutes; reaction temperature: 100°C for the first tower, 80°C for the second tower; speed: 60 m / min;

[0053] The function of the setting machine: setting the polyester to ensure the heat shrinkability of the finished product; temperature: 200°C; speed: 80 m / min; finished width: 118.5 cm.

[0054] 3...

Embodiment 2

[0076] Adopt T / C 45S polyester-cotton fabric through continuous refining, continuous pad dyeing, resin / waterproof co-bath finishing, water-soluble polyvinyl alcohol resin hot-melt transfer bonding process.

[0077] 1. Raw material: T82111

[0078] 2. Refining:

[0079] The refining machine is a continuous refining machine - a heat setting machine.

[0080] The function of the continuous refiner is desizing, refining and bleaching.

[0081] Auxiliary ingredients: sodium hydroxide NaOH: 40g / l, hydrogen peroxide H2O2: 20g / l, metal ion chelating agent: 8g / l, refining detergent: 4g / l, desizing agent: 8g / l, hydrogen peroxide stabilizer: 8g / l, oxalic acid: 2g / l;

[0082] Reaction time: 45 minutes; reaction temperature: 100°C in the first tower, 60°C in the second tower; speed: 40 m / min;

[0083] The function of the setting machine: setting the polyester to ensure the heat shrinkability of the finished product; temperature: 220°C; speed: 40 m / min; finished width: 118.5 cm.

[00...

Embodiment 3

[0107] Adopt T / C 45S polyester-cotton fabric through continuous refining, continuous pad dyeing, resin / waterproof co-bath finishing, water-soluble polyvinyl alcohol resin hot-melt transfer bonding process.

[0108] 1. Raw material: T82111

[0109] 2. Refining:

[0110] The refining machine is a continuous refining machine - a heat setting machine. The function of the continuous refiner is desizing, refining and bleaching. Auxiliary ingredients: sodium hydroxide NaOH: 20g / l, hydrogen peroxide H2O2: 10g / l, metal ion chelating agent: 4g / l, refining detergent: 1g / l, desizing agent: 4g / l, hydrogen peroxide stabilizer: 4g / l, oxalic acid: 2g / l;

[0111] Reaction time: 45 minutes; Reaction temperature: 100°C for the first tower, 80°C for the second tower; Speed: 60 m / min; Function of the heat setting machine: to shape the polyester to ensure the heat shrinkability of the finished product; Temperature: 200°C; Speed: 80 m / min; finished width: 118.5 cm.

[0112] 3. Dyeing:

[0113...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com