Protein chip and its preparing method and use

A protein chip and protein technology, applied in the direction of biochemical equipment and methods, material inspection products, instruments, etc., can solve the problems of protein instability, failure to form products, and difficult storage of chips, so as to solve the problem of degradation over time and avoid unsatisfactory Stable and solve the effect that is not easy to save

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

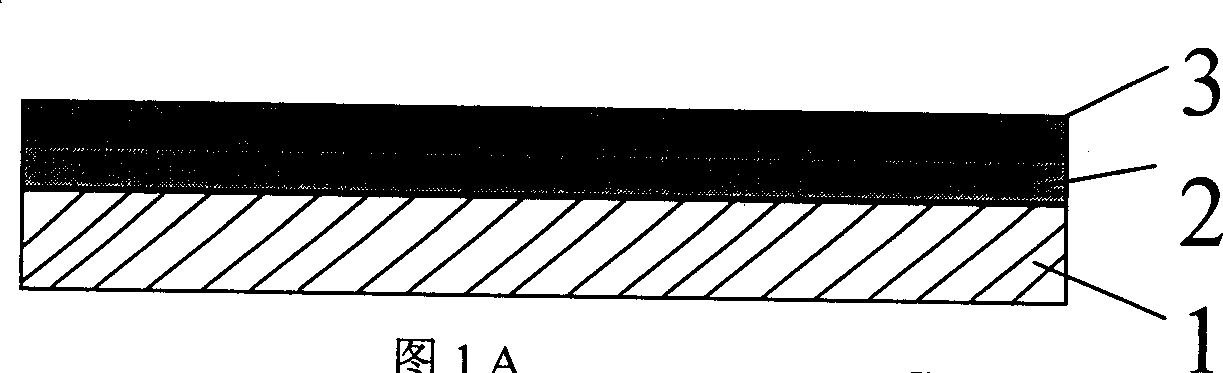

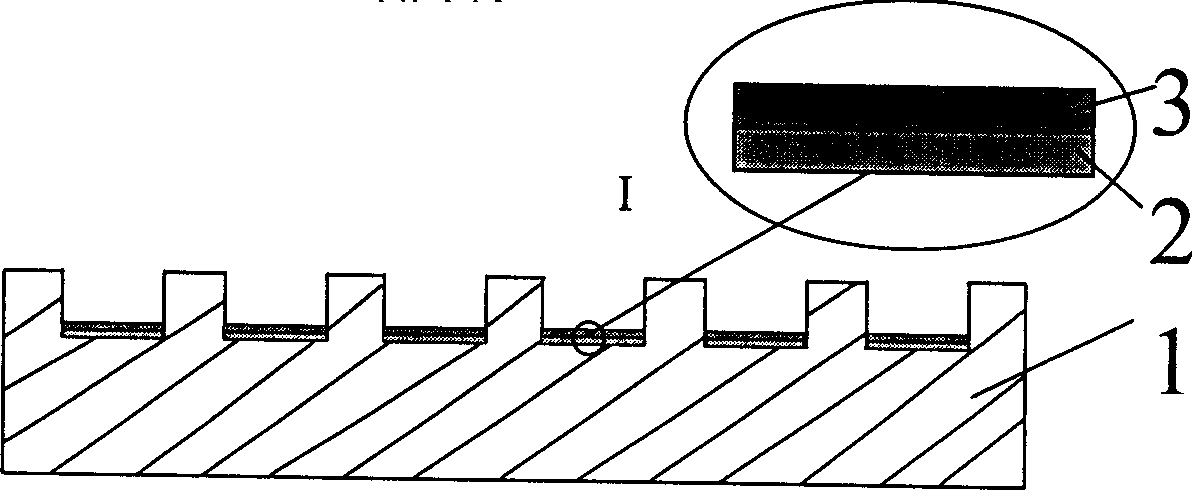

[0040] Example 1: Preparation of a protein chip on a high-density island-shaped protrusion glass substrate

[0041] Step 1: treatment and activation of the substrate surface (see figure 2 shown)

[0042] 1) Rinse the graphite substrate with high-density island-shaped protrusions three times with pure water, and then rinse the glass slide three times with 100% ethanol.

[0043] 2) Place the graphite substrate to be plated on the sample stage in the vacuum evaporation table, place the metal to be plated in the evaporation boat, and place the plated metal at 10 under the melting point of gold. -2 Pa plated gold on the surface of the graphite substrate.

[0044] 3) The coated graphite substrate was placed in a layer containing 10-mercaptodecane-NTA (Ca 2+ ) solution, react at room temperature for more than three hours to obtain a substrate connected with an affinity layer.

[0045] 4) Wash the substrate obtained in the above 3) three times with phosphate buffered saline (PBS)...

Embodiment 2

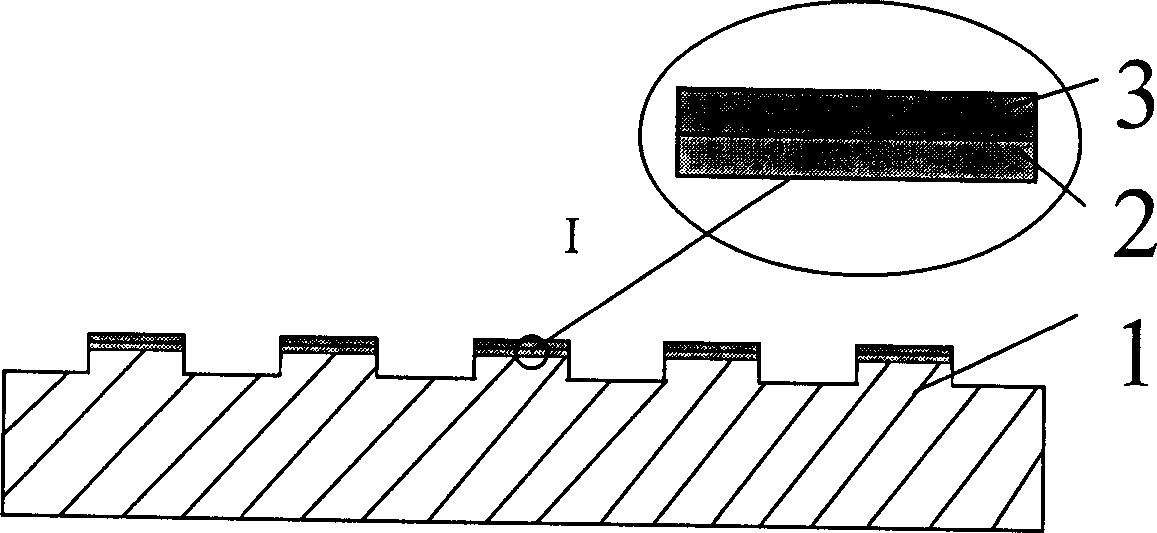

[0058] Example 2: Preparation of protein chips on high-density microporous substrates

[0059] Step 1: Treatment and activation of the chip surface

[0060] 1) Rinse the high-density microporous glass substrate (the cavity is a circular hole with a diameter of 7 microns) three times with water, and then rinse the glass slide three times with 100% ethanol.

[0061] 2) Soak the glass substrate in 0.2M NaOH solution overnight, then wash it three times with high-purity water, and then rinse it once with absolute ethanol.

[0062] 3) Place the cleaned glass substrate in a place containing (CH 3 O) 3 -Si-(CH 2 ) 20 - React in a biotin solution for more than three hours at room temperature to obtain a substrate connected with an affinity layer.

[0063] 4) Wash the substrate obtained in the above 3) three to five times on a shaker with phosphate buffered saline (PBS).

[0064] 5) Wash five times with 70% ethanol, then three times with 95% ethanol, and finally three times with 1...

Embodiment 3

[0072] Example 3: Preparation of Protein Chips on Smooth Substrates

[0073] Step 1: Treatment and activation of the chip surface

[0074] 1) Rinse the smooth quartz substrate three times with water, and then rinse the glass slide three times with 100% ethanol.

[0075] 2) The quartz substrate was soaked overnight in 0.2M HCl solution, then washed three times with high-purity water, and then rinsed once with absolute ethanol.

[0076] 3) Place the cleaned quartz substrate in a place containing (CH 3 O)-Si-(CH 2 ) 22 - Reacting in a solution of glutathione at room temperature for more than three hours to obtain a substrate connected with an affinity layer.

[0077] 4) Wash the substrate in the above 3) with phosphate buffered saline (PBS) on a shaker for a total of three to five times.

[0078] 5) Wash five times with 70% ethanol, then three times with 95% ethanol, and finally three times with 100% ethanol. The prepared substrate connected with the affinity layer is store...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com