Öä

A carbon nanotube and logic technology, applied in the field of micro-nano electronic device circuits, can solve the problems of complex structure and difficult fabrication, and achieve the effects of improving performance and reliability, reducing fabrication difficulty, and reducing gate area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

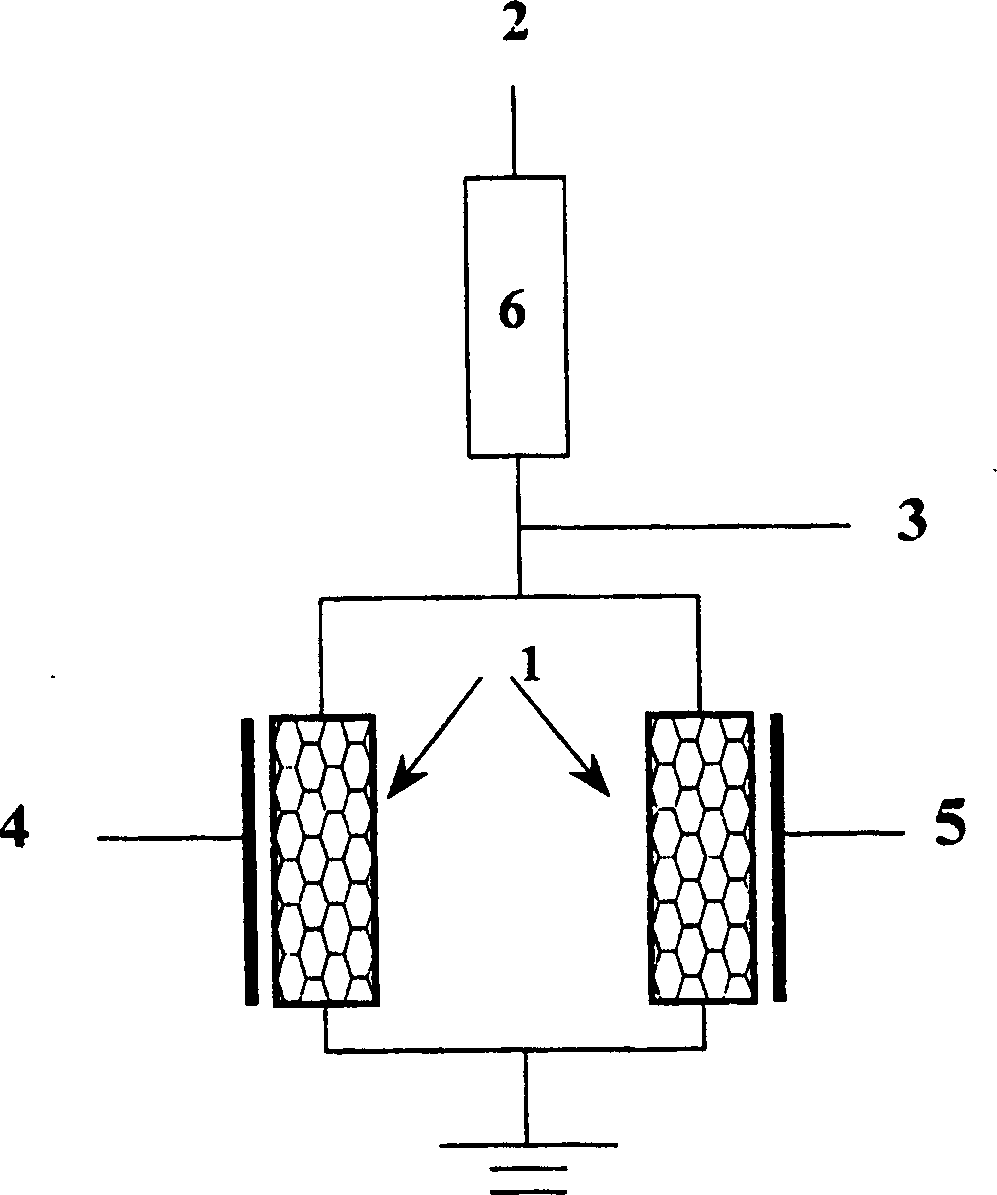

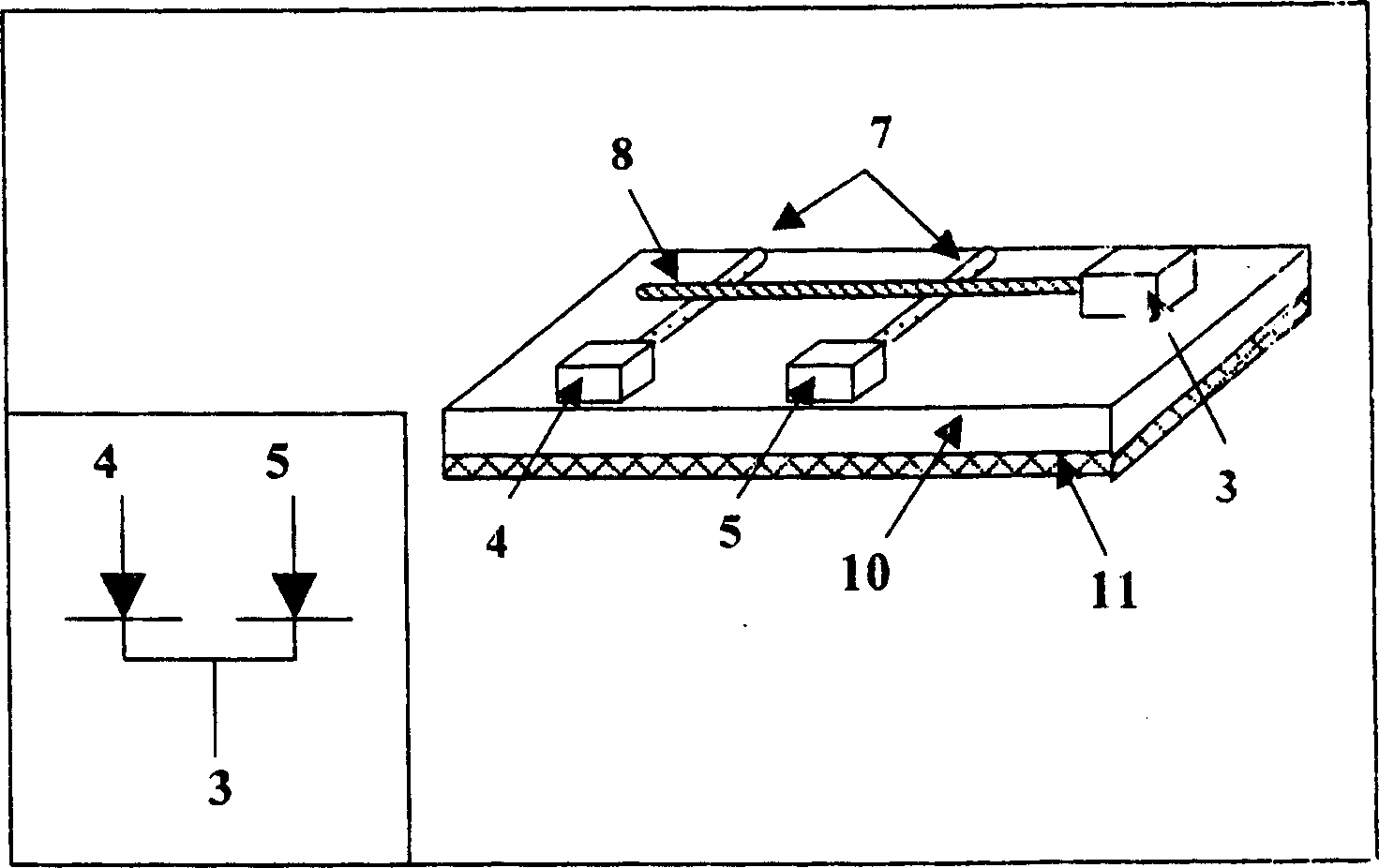

[0056] according to image 3 , 4 and 5 make the "OR" gate logic device of the carbon nanotube double gate structure of the utility model.

[0057] Silicon with (001) orientation is selected as the substrate 11 . Utilize organic vapor phase deposition method (PECVD), prepare the SiO with 300nm thick on the substrate 11 2 Layer 10. First make the gate 4, 5: in SiO 2 Electron photoresist (PMMA) with a thickness of 80 nm is uniformly coated on the insulating layer 10 . The photoresist after electron beam exposure is developed and fixed, and after the exposed photoresist is removed, two grooves with a width of 30 nm and a distance of 50 nm are formed on the photoresist layer. Etching of SiO without photoresist coverage using dry etching 2 , in SiO 2 Two trenches with a width of 30nm, a depth of 30nm and a distance of 50nm are formed on the insulating layer. A layer of Al with a thickness of 30 nm is deposited on the entire surface of the device by electron beam evaporation....

Embodiment 2

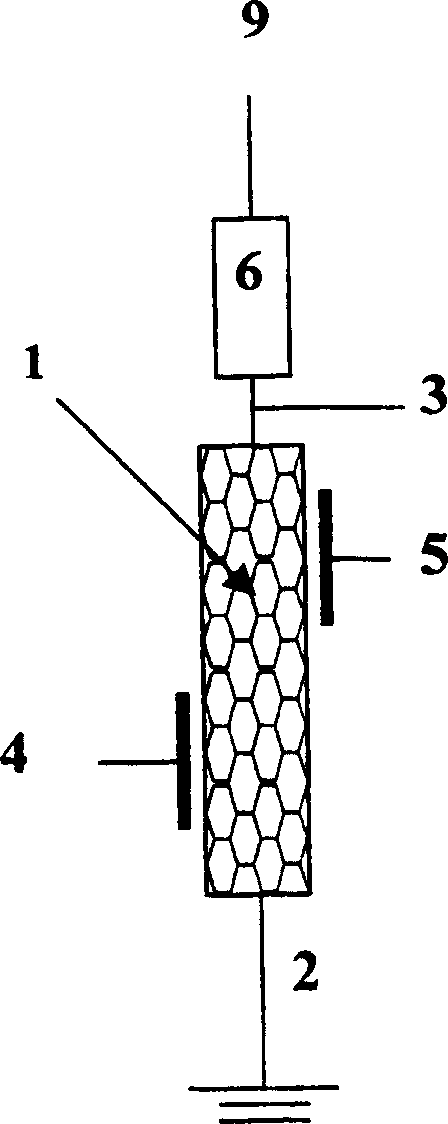

[0059] according to image 3 , 5 and 6 make another "OR" gate logic device with carbon nanotube double gate structure of the present utility model.

[0060] Silicon with (001) orientation is selected as the substrate 11 . Utilize organic vapor phase deposition method (PECVD), prepare the SiO with 300nm thick on the substrate 11 2 Layer 10. First make the gate 4, 5: in SiO 2 Electron photoresist (PMMA) with a thickness of 80 nm is uniformly coated on the insulating layer 10 . The photoresist after electron beam exposure is developed and fixed, and after the exposed photoresist is removed, two grooves with a width of 30 nm and a distance of 50 nm are formed on the photoresist layer. Etching of SiO without photoresist coverage using dry etching 2 , in SiO 2 Two trenches with a width of 30nm and a depth of 30nm are formed on the insulating layer. A layer of Al with a thickness of 30 nm was deposited on the entire device surface by electron beam evaporation. The photoresis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com