Raw material recovery method from active carbon produced by chemical method

A technology for the production of activated carbon and recovery methods, which is applied to chemical instruments and methods, separation methods, and separation of dispersed particles. It can solve problems such as hazards, corrosion of pipelines and equipment, and unrecyclable raw material phosphoric acid, and achieve the effect of protecting the ecological environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

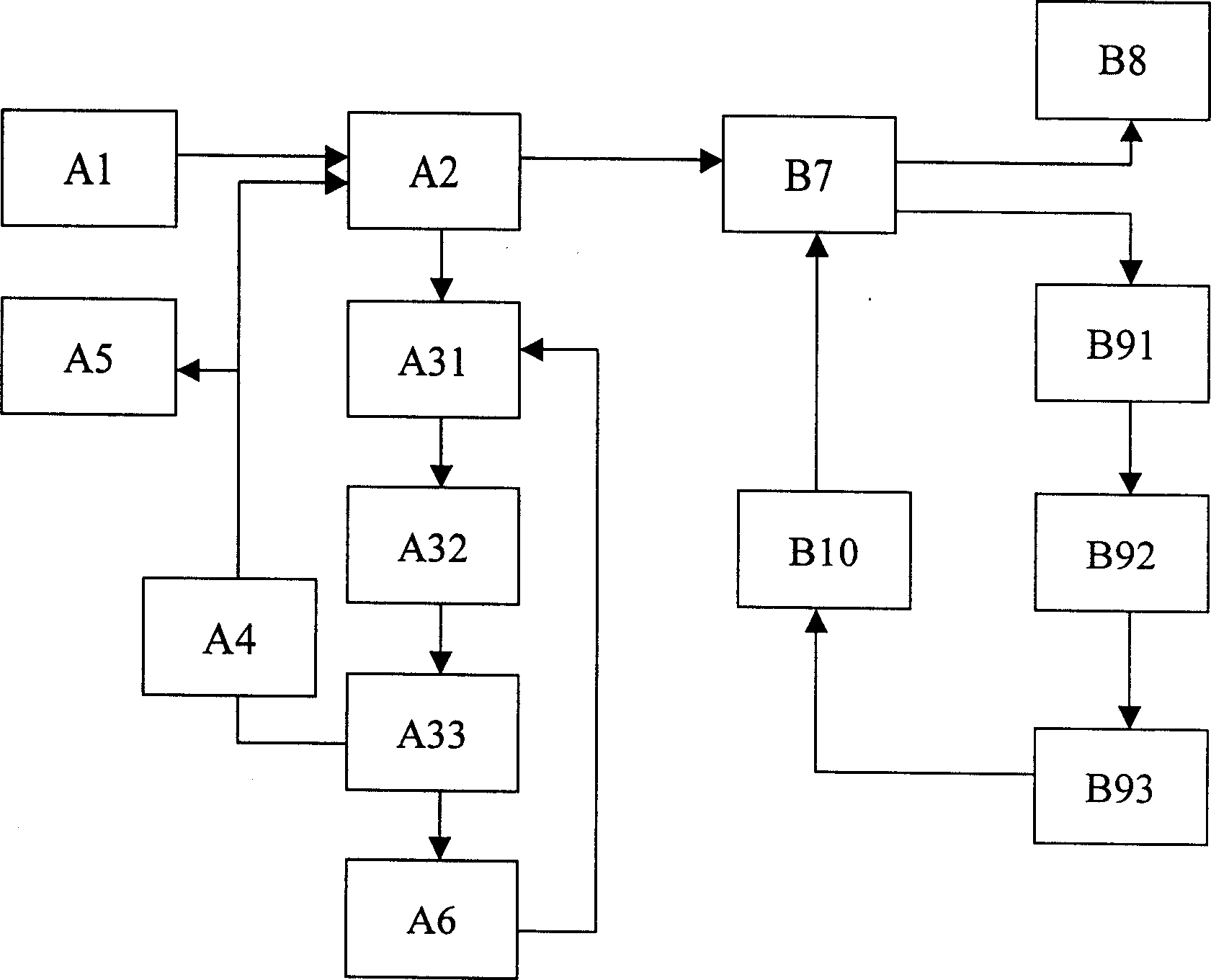

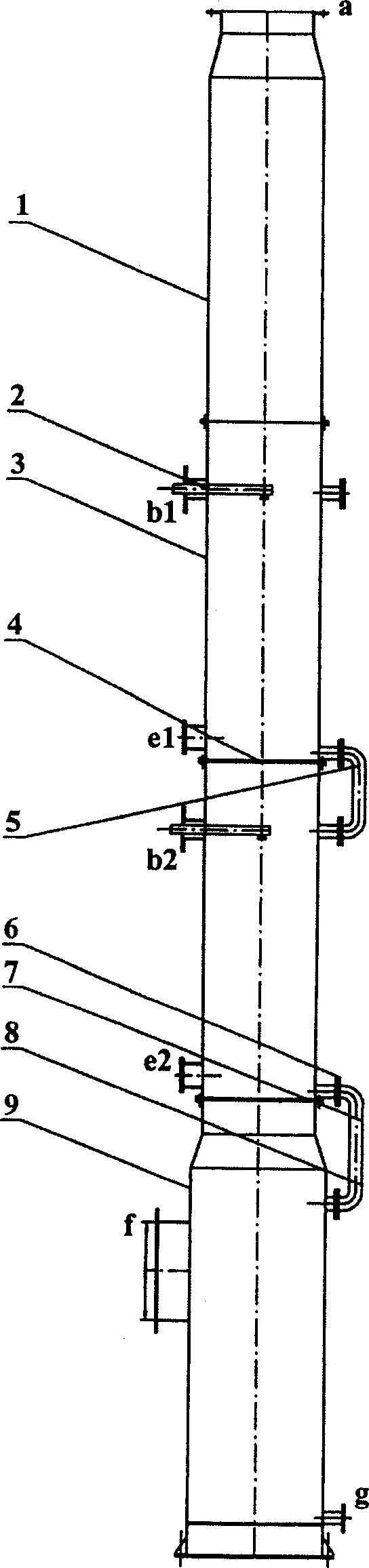

[0030] Depend on figure 1 Visible, establish phosphoric acid recovery tower A2 (referring to in the waste gas outlet of rotary kiln A1 figure 2 ), the recovery tower is made of phenolic fiberglass. The dilute acid recovered by the recovery tower is precipitated and cooled by the three-stage acid liquid precipitation cooling circulation pool A31, A32, A33, and the acid liquid precipitation cooling circulation pool A31~A33 is lined with phenolic glass fiber reinforced plastic layer. The absorption liquid obtained from the acid liquid precipitation cooling circulation pool is sent back to the phosphoric acid recovery tower A2 through the phosphoric acid circulation pump A4, and the liquid that reaches a certain concentration is sent to the production workshop A5, and the dilute acid liquid is replaced again. The ash and slag obtained in the acid liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com