High-brightness small blue luminous particle and its preparation method

A fluorescent powder and small particle technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of reduced luminous efficiency, high equipment requirements, high reaction temperature, etc., and achieve short afterglow time, high luminous purity, and thermal stability good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

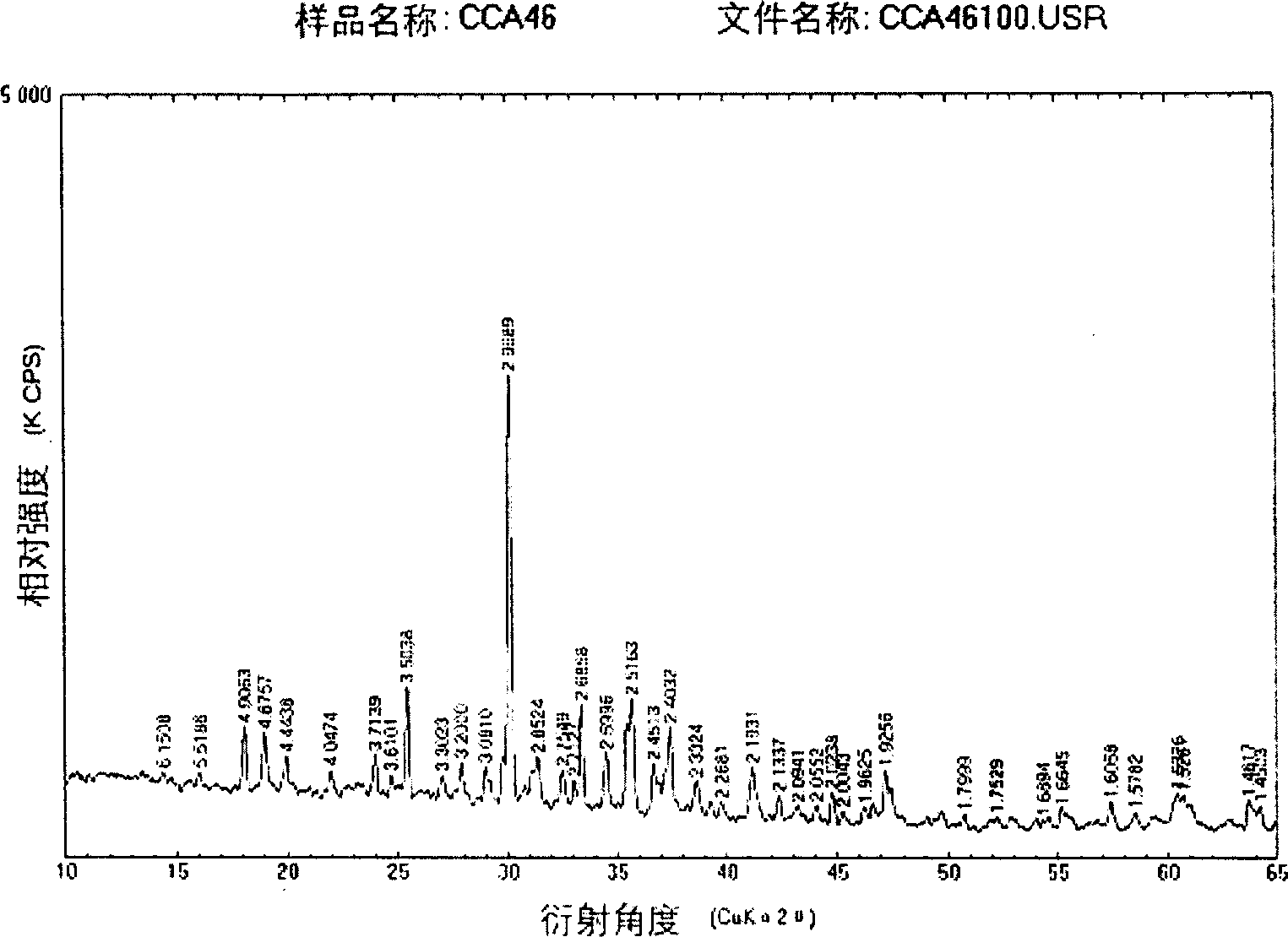

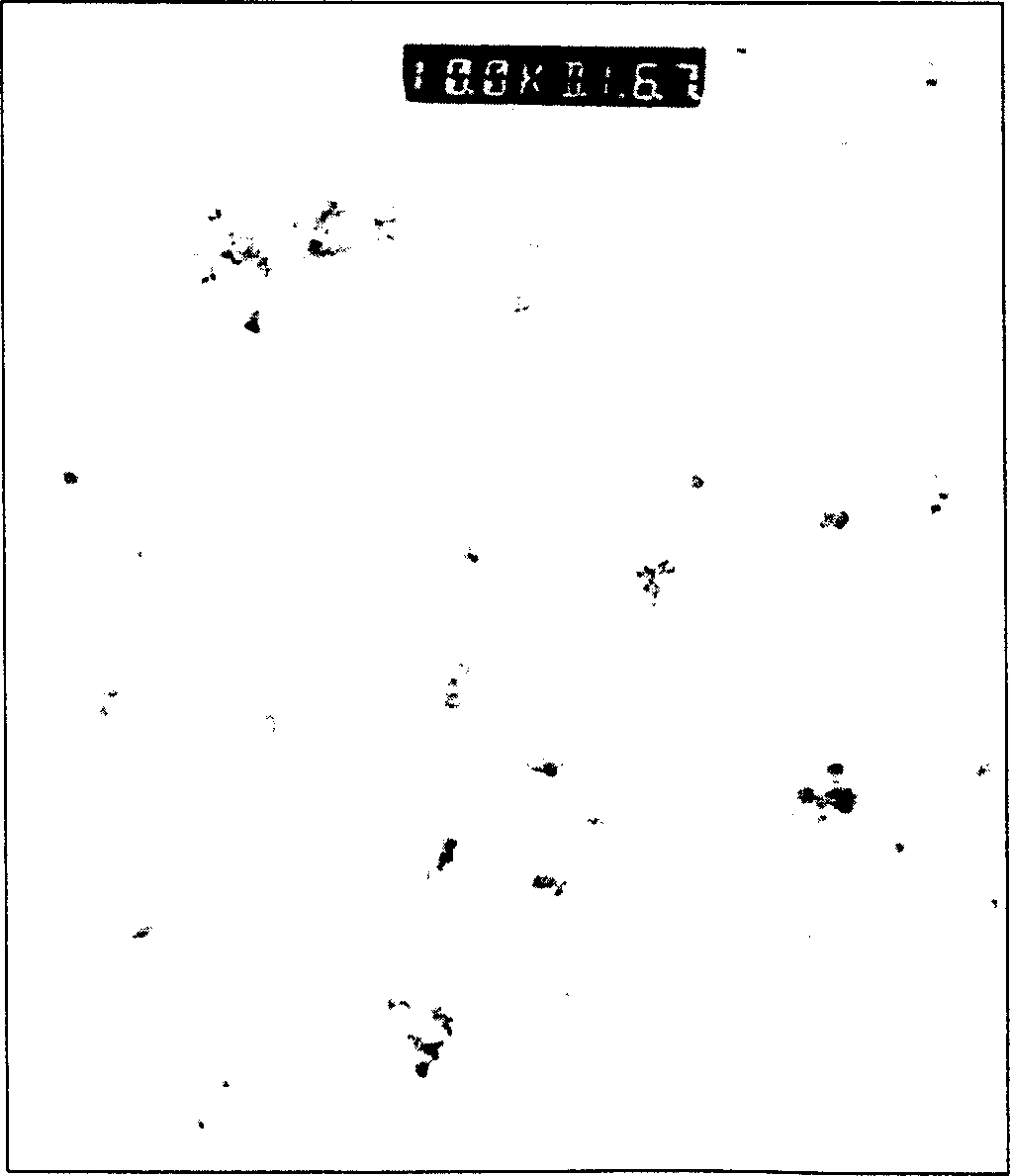

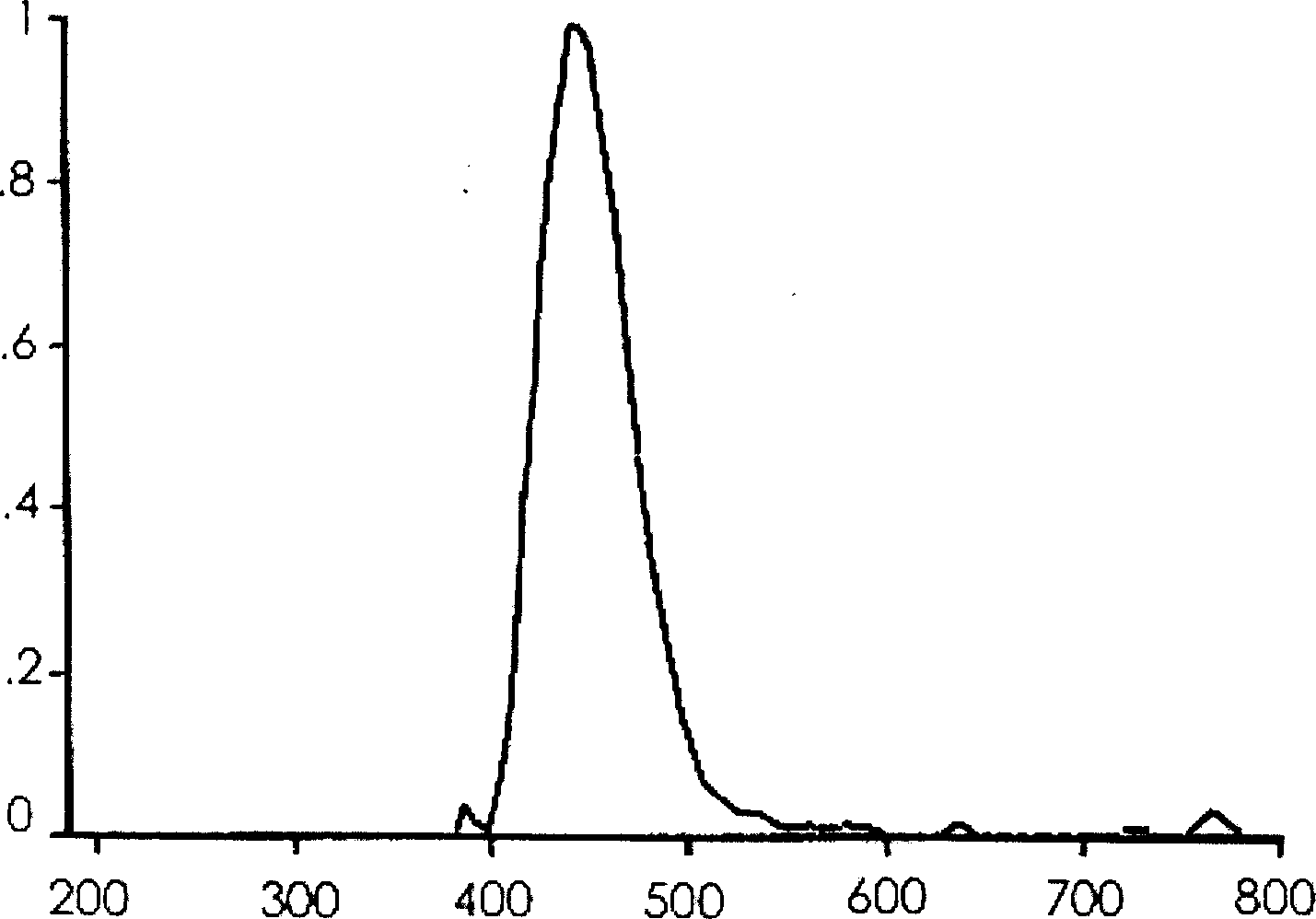

Embodiment 1

[0026] ①According to the stoichiometric ratio according to the molecular formula CaAl 2 o 4 :Eu 2+ 0.005 Weigh 2.804g CaO (98%, A.R), 0.044g Eu 2 o 3 (99.99%) was dissolved with hydrochloric acid, and 28.4035g AlCl was added 3 ·6H 2 O (85%, A.R), dubbed 160ml solution.

[0027] ② Stir the solution, add ammonia water to adjust the pH value to 4.5-6.5, add 20.9061 g of oxalic acid (the sum of oxalic acid: metal ions = 1.1-1.3: 1), add ammonia water to adjust the pH value to 4.5-6.5, and continue to stir the solution for 30 minutes.

[0028] ③Put the solution in a water bath and keep the temperature at 25-45°C for 12-24 hours to form a white precipitate.

[0029] ④ Wash and filter the white precipitate, and dry it in an oven at 75-95°C to obtain oxalate powder.

[0030] ⑤Put the oxalate into the crucible, under N 2 、H 2 (H 2 Accounting for 10-11%) under a reducing atmosphere, heat at 450-550°C and 850-950°C for 20-40 minutes respectively, and then calcinate at 1250-135...

Embodiment 2

[0032] ①According to the stoichiometric ratio according to the molecular formula CaAl 2.1 o 4.5148 :Eu 2+ 0.08 Weigh 2.804g CaO (98%, A.R), 0.704g Eu 2 o 3 (99.99%) was dissolved with hydrochloric acid, and 29.8237g AlCl was added 3 ·6H 2 O (85%, A.R), dubbed 160ml solution.

[0033] ② Stir the solution, add ammonia water to adjust the pH value to 4.5-6.5, add 21.3146 g of oxalic acid (the sum of oxalic acid: metal ions = 1.1-1.3: 1), add ammonia water to adjust the pH value to 4.5-6.5, and continue to stir the solution for 20-40 minutes.

[0034] ③Put the solution in a water bath and keep the temperature at 25-45°C for 12-24 hours to form a white precipitate.

[0035] ④ Wash and filter the white precipitate, and dry it in an oven at 75-95°C to obtain oxalate powder.

[0036] ⑤Put the oxalate into the crucible, under N 2 、H 2 (H 2 Accounting for 8-11%) in a reducing atmosphere, heat at 450-550°C and 850-950°C for 20-40 minutes respectively, and then calcinate at 125...

Embodiment 3

[0038] ①According to the stoichiometric ratio according to the molecular formula CaAl 2.4 o 4.6 :Eu 2+ 0.02 Weigh 2.804g CaO (98%, A.R), 0.176g Eu 2 o 3 (99.99%) dissolved with hydrochloric acid, added 34.0842g AlCl 3 ·6H 2 O (85%, A.R), dubbed 160ml solution.

[0039]② Stir the solution, add ammonia water to adjust the pH value to 4.5-6.5, add 24.5836 g of oxalic acid (the sum of oxalic acid: metal ions = 1.1-1.3: 1), add ammonia water to adjust the pH value to 4.5-6.5, and continue to stir the solution for 20-40 minutes.

[0040] ③Put the solution in a water bath and keep the temperature at 20-35°C for 12-24 hours to form a white precipitate.

[0041] ④ Wash and filter the white precipitate, and dry it in an oven at 75-95°C to obtain oxalate powder.

[0042] ⑤Put the oxalate into the crucible, under N 2 、H 2 (H 2 Accounting for 10-11%) in a reducing atmosphere, heat at 450-550°C and 850-950°C for 20-40 minutes respectively, and then calcined at 1250-1350°C for 4 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com