Kaolin/dimethyl sulphoxide/carboxymethyl starch ternary system nanotube composite electrorheological fluid materials

A technology of dimethyl sulfoxide and carboxymethyl starch is applied in the directions of base material, lubricating composition, petroleum industry, etc., and can solve the problems of complex preparation process, high cost, low mechanical value and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

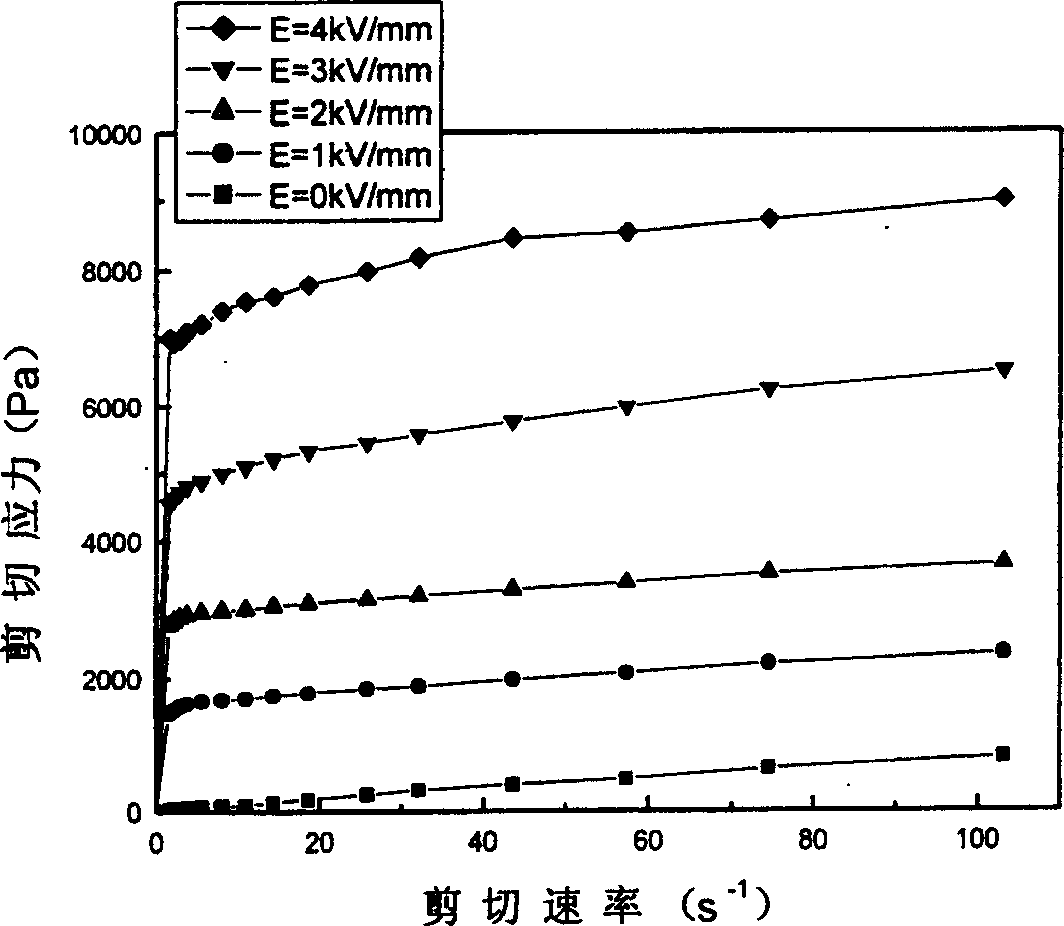

[0009] Embodiment 1: First weigh 3g of kaolin and put it into a weighing bottle, then use a dropper to absorb an appropriate amount of dimethyl sulfoxide, slowly add it to the kaolin, and shake it evenly while adding it dropwise. The amount of dimethyl sulfoxide is about 30% by weight of pure earth. After the sample was ultrasonically oscillated for 30 minutes, it was placed in an airtight container and reacted in an oven at 80° C. for 10 hours to prepare the kaolin / dimethyl sulfoxide intercalation complex. At the same time, add 20g of starch to 150ml of absolute ethanol, stir for 1 hour, add 15g of NaOH, continue to stir for 1 hour, raise the temperature to 50°C, add 15g of NaOH and 71g of chloroacetic acid, stir at 50°C for more than 5 hours, the reaction is complete, and then filter with suction , washed, and vacuum-dried at 60°C for 5 hours to obtain carboxymethyl starch. Add 3.5 g of carboxymethyl starch into 50 ml of water, stir at room temperature for 10 hours, then sl...

Embodiment 2

[0010] Embodiment two: (carboxymethyl starch electrorheological fluid)

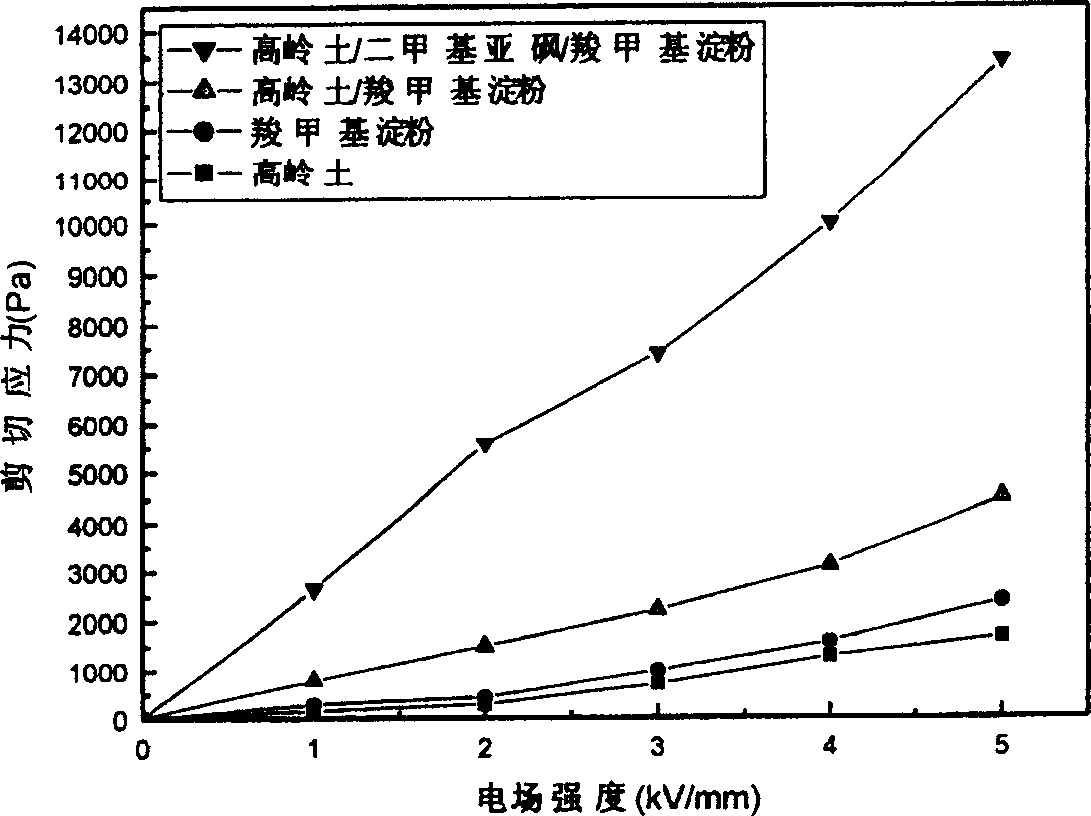

[0011] First add 20g of starch to 150ml of absolute ethanol, stir for 1 hour, add 15g of NaOH, continue to stir for 1 hour, raise the temperature to 50°C, add 15g of NaOH and 71g of chloroacetic acid, stir at 50°C for more than 5 hours, and the reaction is complete. After suction filtration, washing, and vacuum drying at 60°C for 5 hours, carboxymethyl starch is obtained, and then it is mixed with methyl silicone oil in a certain proportion to make electrorheological fluid. The relationship between the shear stress of the electrorheological fluid and the electric field strength is shown in the attached figure 1 shown.

Embodiment 3

[0012] Embodiment three: (pure kaolin electrorheological fluid)

[0013] The electrorheological fluid was prepared by kaolin and methyl silicone oil dried at 120°C for 2 hours in a certain proportion. The relationship between the shear stress of the electrorheological fluid and the electric field strength is shown in the attached figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com