Technique for preparing mead

A technology of manufacturing technology and honey wine, which is applied in the field of manufacturing technology of honey wine, can solve the problems of increasing social instability, loss of life and property, and large food consumption, so as to improve nutritional value, crystal clear wine body, promote The effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

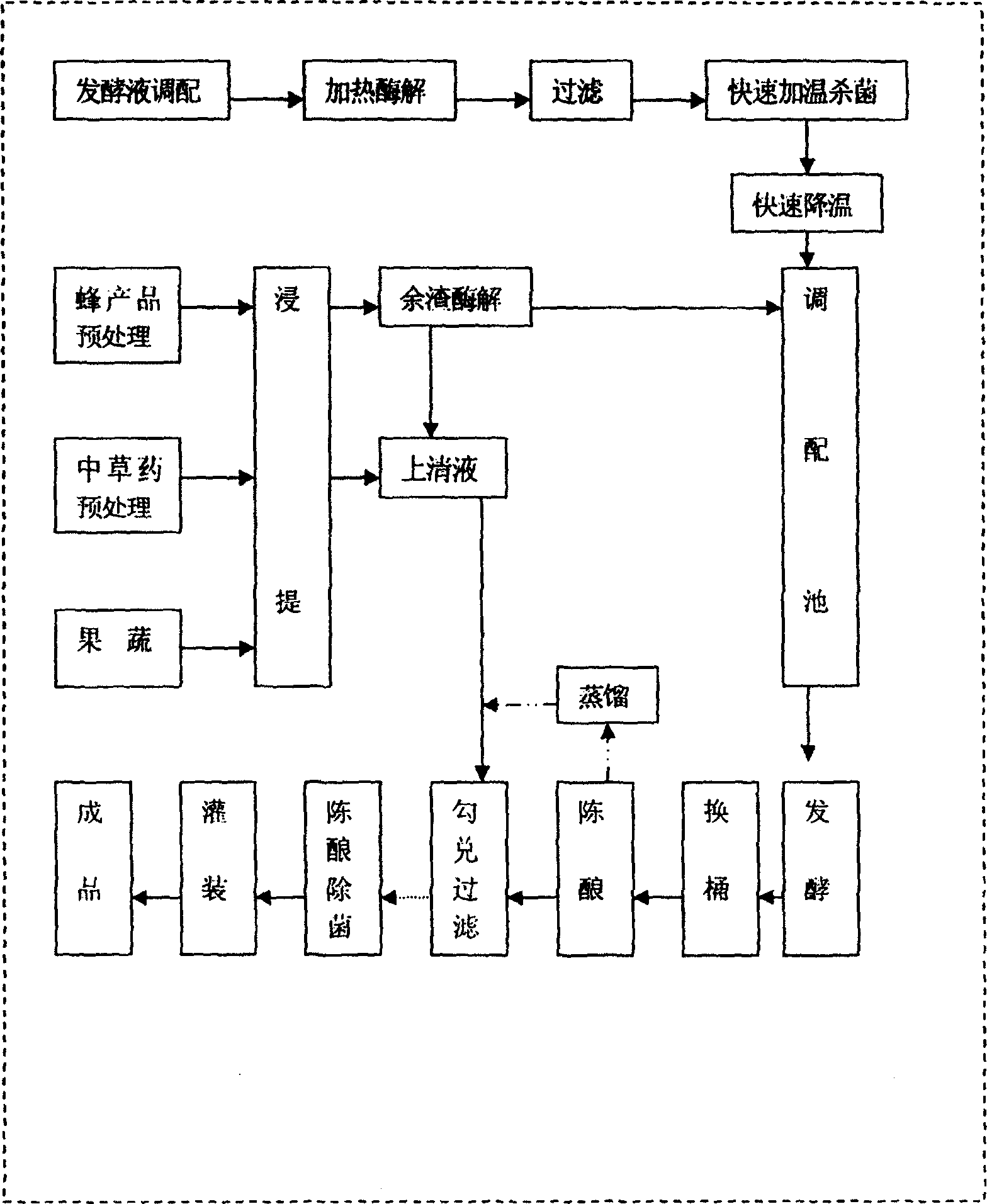

Image

Examples

Embodiment 1

[0018] When brewing mead with an alcohol content of 2%-28%:

[0019] 1. Take high-quality honey and purified water to prepare a fermented liquid with a specific gravity of 1.08-1.2, heat it to 38-50°C, apply pectinase for enzymatic hydrolysis and filtration, then quickly heat up to 70-85°C and keep it for 2-6 minutes Immediately after sterilization, quickly cool down to 35°C and put it into the preparation pool for use;

[0020] 2. Extract the propolis with distilled alcohol base for 2-15 days, take the supernatant for later use, grind, dilute and enzymatically hydrolyze the residue, put the supernatant for later use, and put the rest into the blending pool for later use;

[0021] 3. According to different types of products, ginseng is selected for distilled wine base extraction, the supernatant is filtered and used for later use, and the residue is ground and boiled for enzymolysis.

[0022] 4. According to different product varieties, choose aloe vera for soaking, grinding,...

Embodiment 2

[0028] When the alcohol content is 28%--55%:

[0029] Items 1-6 are the same as the above example.

[0030] 7. After 3-15 days of fermentation, change barrels and age for more than 30 days, filter and distill, and then add enzymatic hydrolysis supernatant and bee product pretreatment process, Chinese herbal medicine pretreatment process, and fruit and vegetable pretreatment process. The extracts are blended and filtered together. After standardization, they are sealed and heated quickly to 60°C-75°C and kept for 3-10 minutes for sterilization. After sterilization, they are immediately cooled down to below 35°C and pumped into aging tanks for more than 30 days of aging.

[0031] 8. Sterilization, filling, labeling, and boxing are finished products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com