Permeable medical polyurethane film and its prepn and application

A technology of polyurethane and gas-permeable membranes, applied in medical science, prostheses, dilators, etc., can solve problems such as long-term curative effect and tissue necrosis, and achieve the effect of avoiding normal tissue necrosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Dissolve Jm80 medical polyurethane in tetrahydrofuran to prepare a 20% (mass percentage) slurry, and let it stand for about 24 hours to ensure full dissolution and defoaming, and the obtained saturated medical polyurethane solution is ready for use.

[0028] Take a piece of flat glass and go through surface cleaning treatments such as acetone cleaning-blowing-drying-water cleaning-blowing-drying successively. Brush a layer of polyurethane slurry on the glass surface with a thickness of about 50 microns. Pre-drying in air at 25°C and 60% relative humidity for 5 minutes until the membrane is semi-dry, and the semi-dry membrane together with the glass plate is immersed in water to fully solidify the membrane gel. Take out the glass plate and carefully peel off to obtain the medical polyurethane breathable membrane of the present invention.

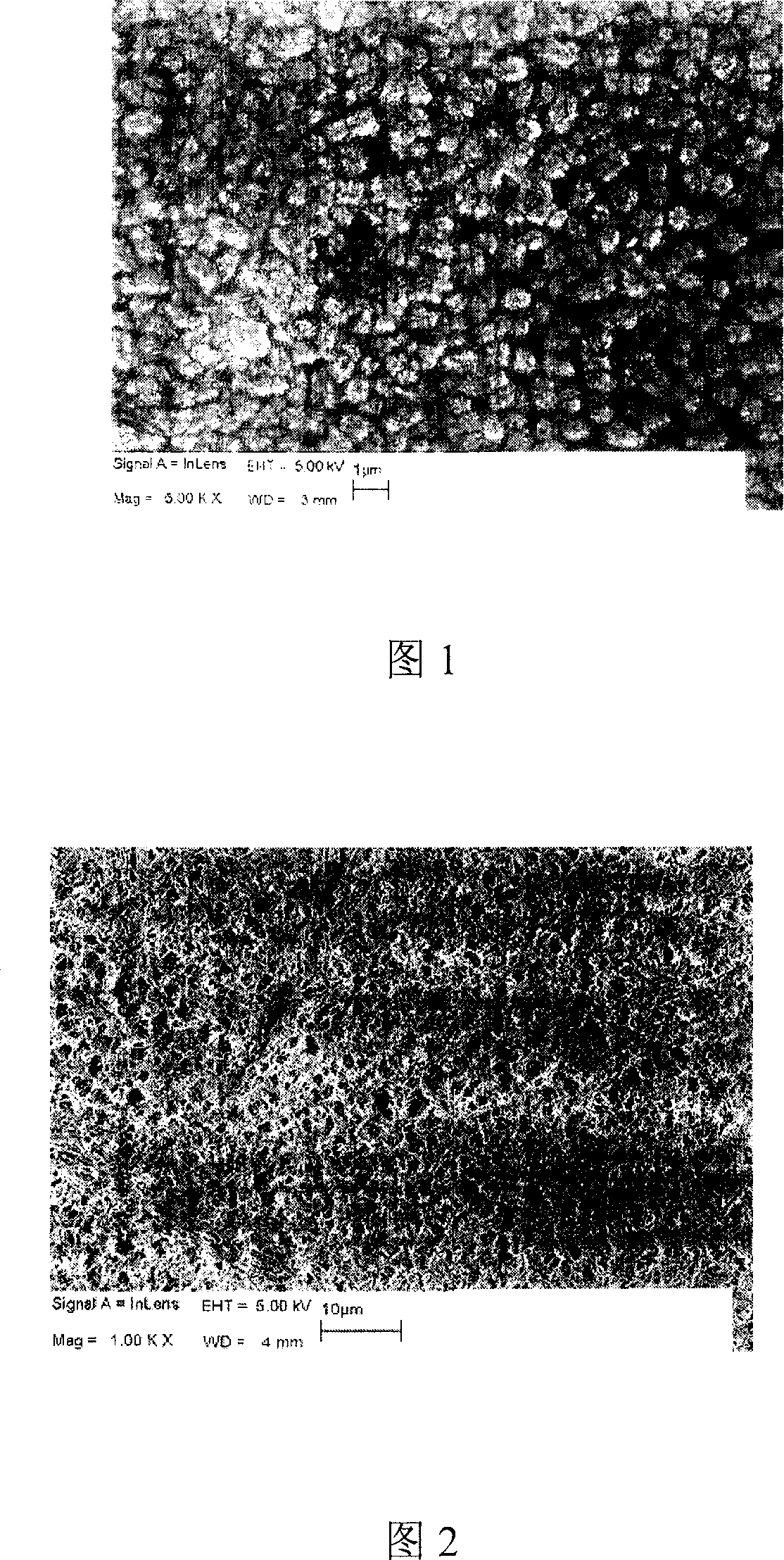

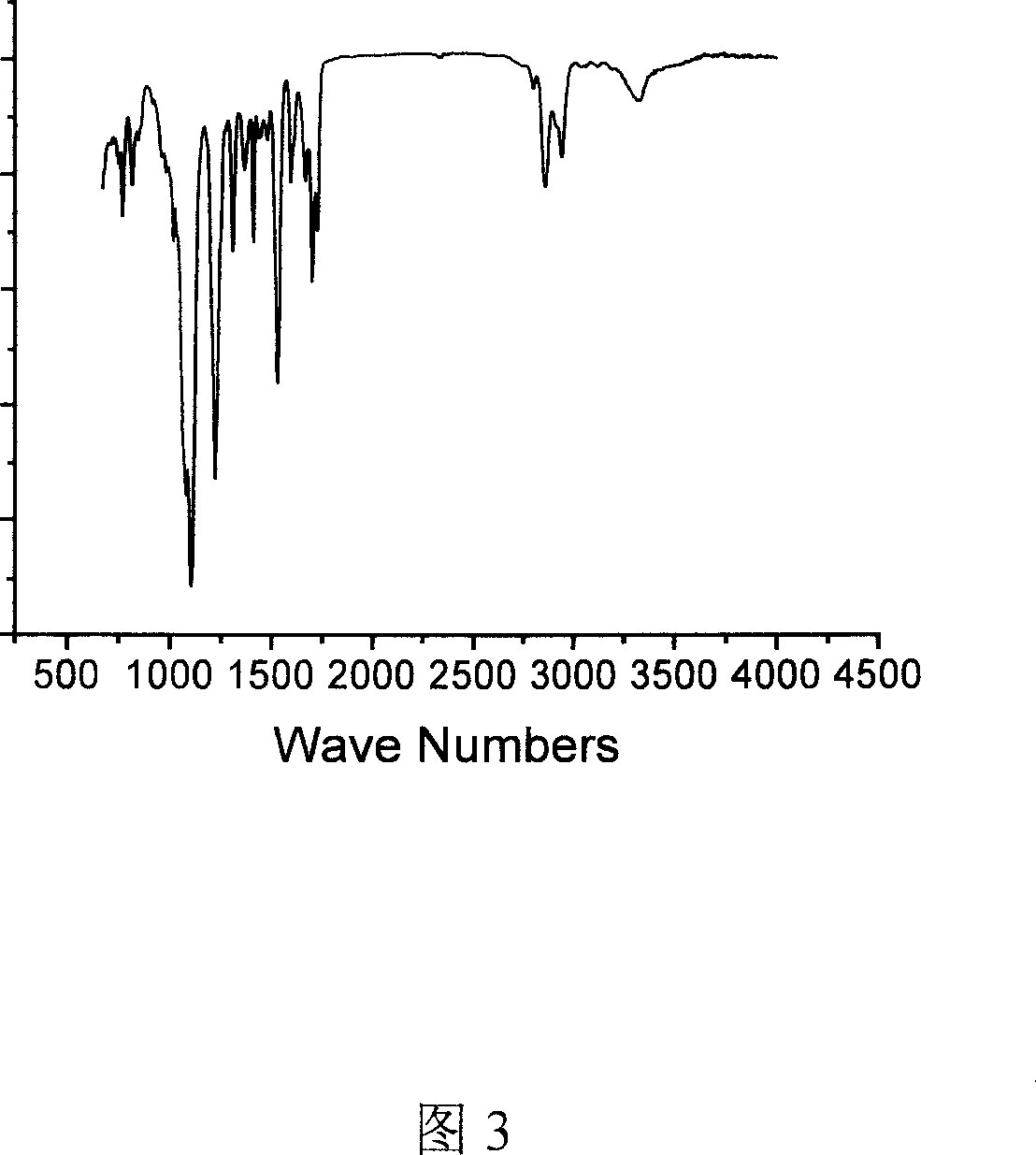

[0029] The appearance of the polyurethane film is pale white and almost transparent. The two surfaces of the film have different microsco...

Embodiment 2

[0031] Dissolve Jm80 medical polyurethane into N,N-dimethylformamide to prepare a slurry of 18% (mass percentage), and add 2% (volume percentage) of acetone to the slurry to ensure full dissolution and defoaming before use. Brush a layer of polyurethane slurry on the clean glass surface with a thickness of about 100 microns. Pre-drying in air at 15°C and 50% relative humidity for 10 minutes until the film is semi-dry, immerse the glass plate in a sodium chloride solution to fully gel and solidify. Take out the glass plate and carefully peel off to obtain the medical polyurethane breathable membrane of the present invention. Observing the surface morphology of the film under an electron microscope, 0.1 to 1 micron micropores are also formed in the film.

Embodiment 3

[0033] Dissolve Jm80 medical polyurethane into N,N-dimethylformamide to prepare a slurry of 18% (mass percentage), and add 5% (volume percentage) of methyl ethyl ketone to the slurry to ensure full dissolution and defoaming before use. Brush a layer of polyurethane slurry on the clean glass surface with a thickness of about 60 microns. Pre-drying in air at 30°C and 80% relative humidity for 2 minutes until the film is semi-dry, immersing the glass plate in an ethanol solution to fully gel and solidify. Take out the glass plate and carefully peel off to obtain the medical polyurethane breathable membrane of the present invention. Observing the surface morphology of the film under an electron microscope, 0.1 to 1 micron micropores are also formed in the film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com