Industrialized product of plant straw feeding stuff and its preparing method

A plant straw and product technology, which is applied in the fields of industrial straw animal feed, production of the above products, and preparation and processing of the above products, can solve the problem of staying in small-scale applications and not being able to form industrialized production, transportation and commercial sales of straw feed products, highways, etc. Civil aviation and other traffic side effects and other issues, to avoid uneven fermentation, shorten the time of production and maturity, and prolong the effect of storage and shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Use the RC500 straw kneading machine to knead the collected dry yellow corn stalks. The raw materials are pushed in from the inlet, cut by the cutter and enter the drum. The straw is crushed by the impact of the hammer and the interaction with the conical plate, and then the crushed straw is crushed by the centrifugal action of the wind blade. The machine is discharged from the discharge port. Adjust the rubbing effect of the straw and the amount of scrap by adjusting the number of hammers. Reduce the number of hammers, lengthen the discharging straw, and reduce the scrap, increase the hammer, shorten the discharging straw and increase the scrap. After adjustment, the length of the kneaded straw silk is controlled between 3 and 5 cm to meet the requirements.

[0034] 2. Preparation of straw fermentation inoculants.

[0035] 1. Initial strain:

[0036] Existing strains are used, including Lactobacillus plantarum, Debaryomyces polymorphus, Trichoderma reesei, and Bacillus ...

Embodiment 2

[0063] Example 2: The process is the same as that of Example 1, except that the added microbial preparation is a commercial product "Xinjiang Micro-Storage King" mainly made of lactic acid bacteria. The ratio and method are the same as those in the example, which will also reduce spoilage. proportion.

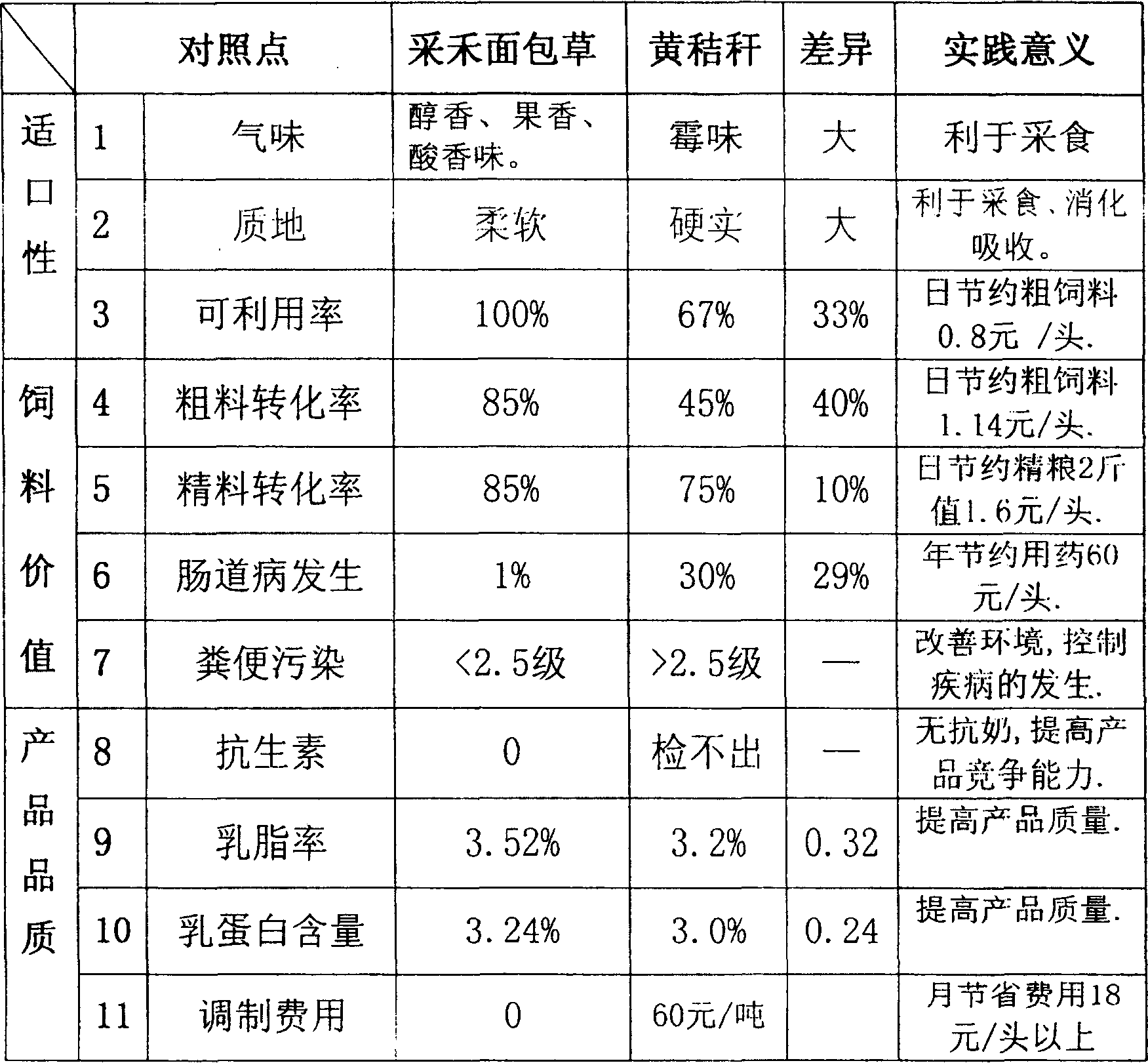

[0064] Analysis of technical indicators of the product of the present invention:

[0065] 1. Comparison of the nutritional value of the product of the present invention and unfermented straw.

[0066] A: The nutritional value of roughage before fermentation (%):

[0067]

Feed

Crude protein

Crude fat

Crude fiber

No nitrogen leaching

Out

Comprehensive net

can

89.2

5.9

0.9

30.4

50.2

3.61

Wheat straw

88.0

5.6

1.6

33.9

41.1

2.29

Sweet Potato Vine

88.0

2.7

2.7

28.5

39.0

3.64

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com