Ceramic heater

A ceramic heater and heater technology, applied in ohmic resistance heating, heating element shape, electric heating device, etc., to achieve the effect of less workpiece pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0184] (1) A mixture containing 100 parts by weight of aluminum nitride powder (manufactured by Tokuyama Co., average particle diameter 1.1 µm), 4 parts by weight of yttrium oxide (average particle diameter 0.4 µm) and 12 parts by weight of acrylic adhesive The mixture and the rest of the alcohol composition were spray-dried to make granular powder, and the aluminum nitride powder contained Na and B with concentrations of 0.1ppm and 0.8ppm respectively.

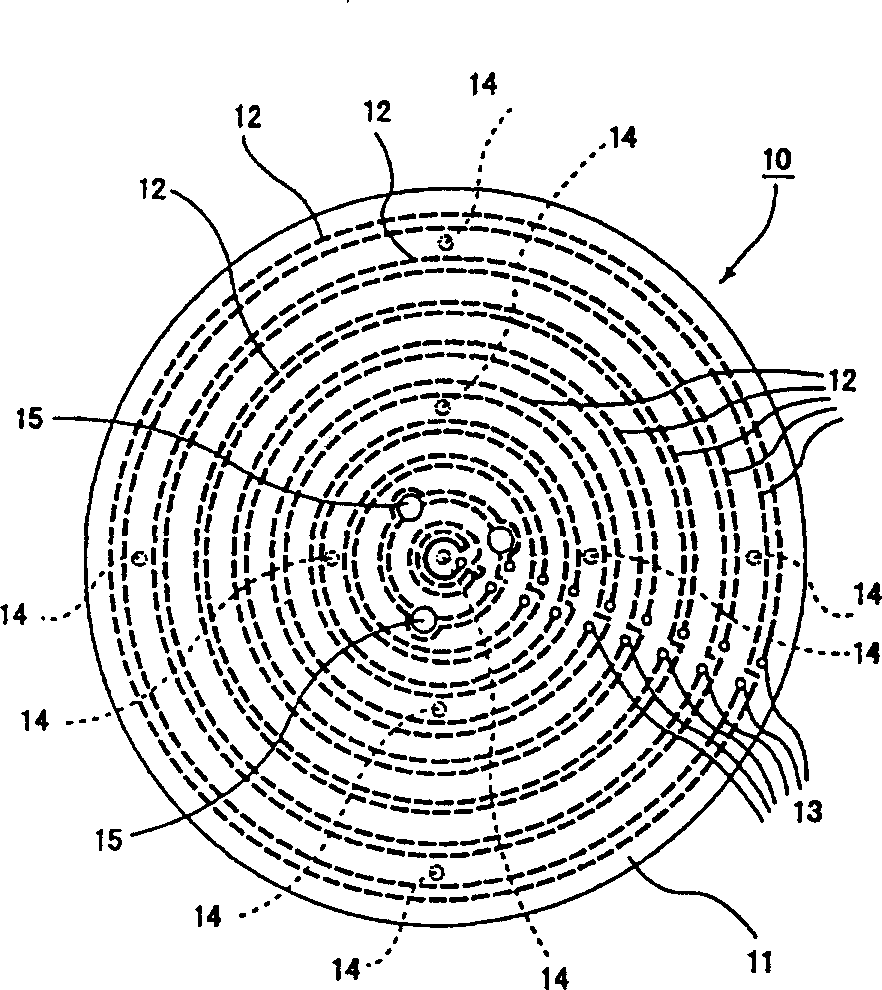

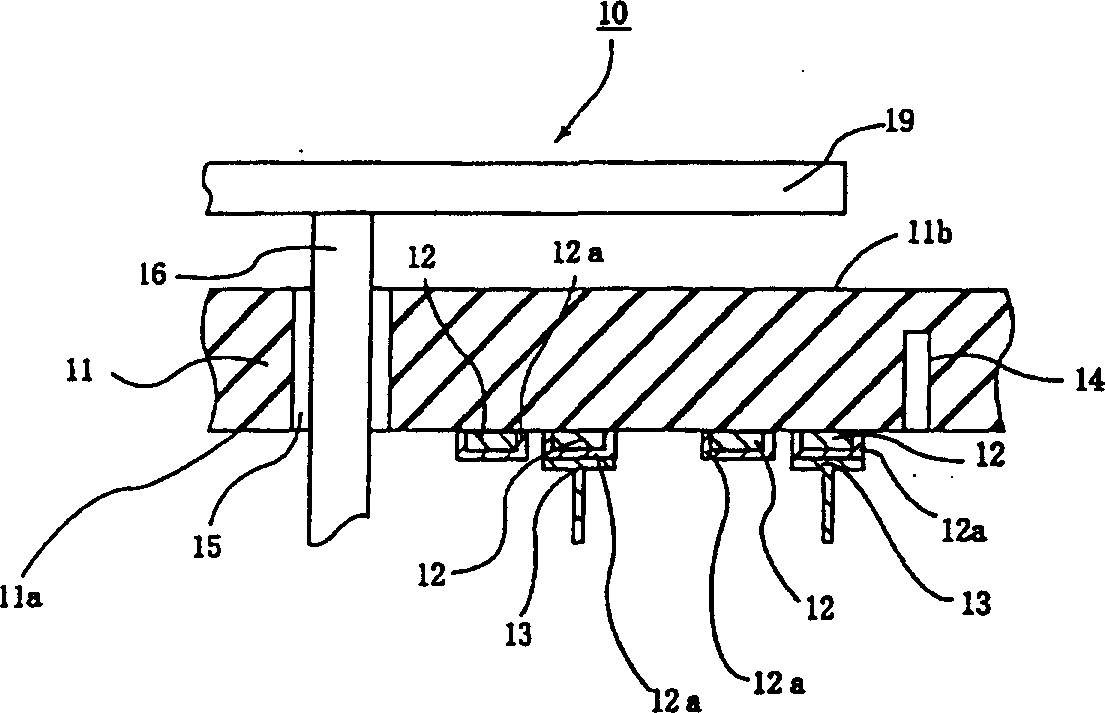

[0185](2) The above-mentioned granular powder is put into a metal mold and formed into a green board. The green board was drilled to form holes corresponding to through holes 15 for receiving semiconductor wafer support pins and holes corresponding to blind holes 14 for embedding thermocouples (1.1 mm diameter x 2 mm deep).

[0186] (3) Next, at 1800°C and 200 kg / cm 2 Next, hot press the green plate obtained by forming to form a 3 mm thick aluminum nitride plate.

[0187] From this plate, a disc with a diameter of 210 mm wa...

Embodiment 2

[0204] Containing 100 parts by weight of aluminum nitride powder (manufactured by Tokuyama Co., average particle diameter 1.1 µm), 5 parts by weight of calcium oxide (average particle diameter 0.3 µm), and 12 parts by weight of an acrylic binder and The rest is alcohol composition spray-dried to make particle powder, the aluminum nitride powder contains Na and B at concentrations of 0.1ppm and 0.8ppm respectively. Completely repeat the other steps of Example 1 to make a ceramic heater.

Embodiment 3

[0206] Containing 100 parts by weight of aluminum nitride powder (manufactured by Tokuyama Co., with an average particle size of 1.1 µm), 3 parts by weight of Li 2 O (average particle size 0.3 micron), 2 parts (weight) Pb 2 O (average particle diameter 0.3 micron) and 12 parts (weight) acrylic adhesive and the composition spray-drying that all the other are alcohol make particle powder, and described aluminum nitride powder contains the Na that concentration is respectively 0.1ppm and 0.8ppm and B. Completely repeat the other steps of Example 1 to make a ceramic heater.

[0207] Next, the surface of the heater board 11 was polished to Rmax=0.8 micron with 0.5 micron diamond paste, after which a ceramic heater was produced as described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap