Solar cell adopting organic/inorganic nano doped quasi-solid state electrolyte, and its preparation method

A solar cell and inorganic nanotechnology, applied in the field of solar cells, can solve problems such as affecting the stability of solar cells, easy agglomeration of nanoparticles, and achieve the effects of solving compatibility, solving phase separation, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

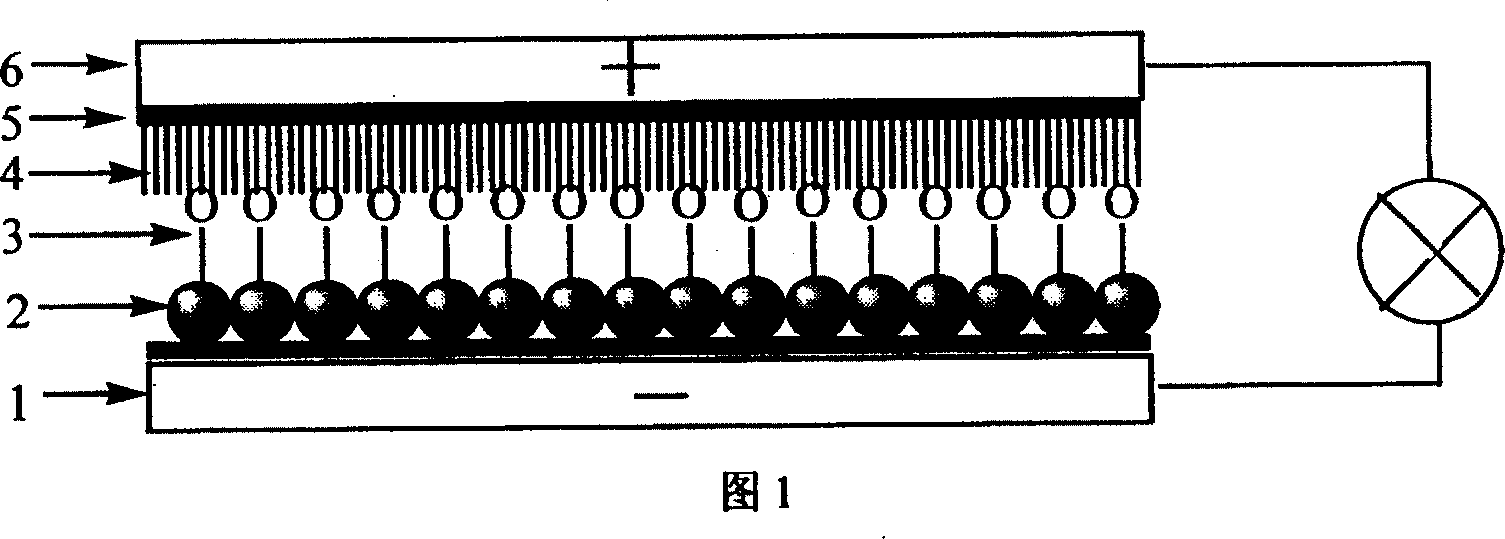

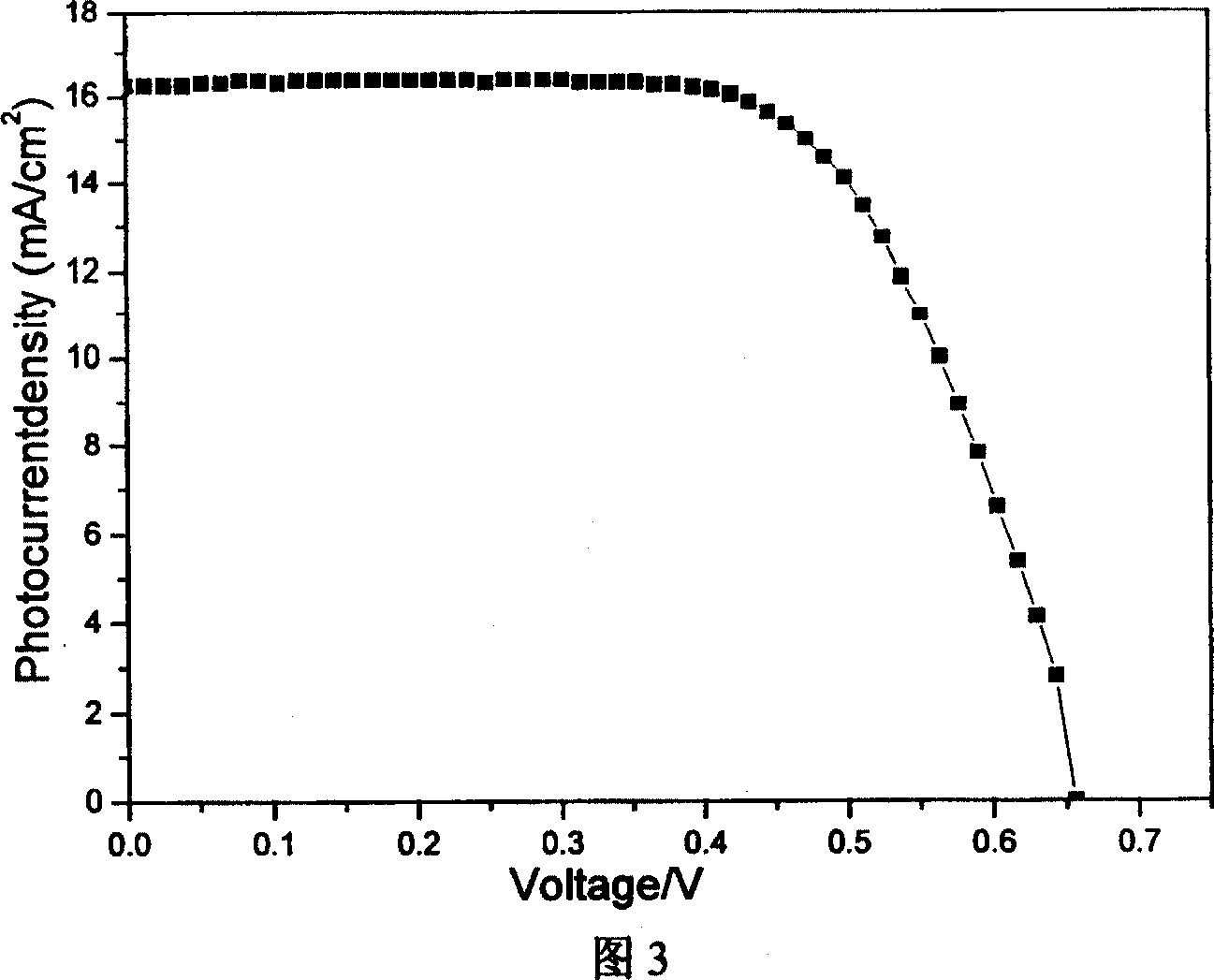

[0028] Embodiment 1: A titanium dioxide nanocrystalline film electrode is placed in 5 * 10 -5 mol / L N3 dye in ethanol solution for 48 hours to sensitize. Add dropwise 0.1 ml containing 0.1 mol / l I 2, 0.1 mol / L LiI, 0.5 mol / L 4-tert-butylpyridine, 0.6 mol / L 1-methyl-3-propyl imidazolium salt in acetonitrile / propylene carbonate (volume ratio=1:1) solution, then A piece of platinum-coated ITO glass is placed on the dye-sensitized nano-TiO2 crystal film and clamped with a clamp for measurement. at 100mW / cm 2 Under white light irradiation, the open circuit photovoltage of the battery is 634mV, and the short circuit photocurrent is 17.6mA / cm 2 , fill factor 0.64, energy conversion efficiency 7.2%, half-life 125 hours.

Embodiment 2

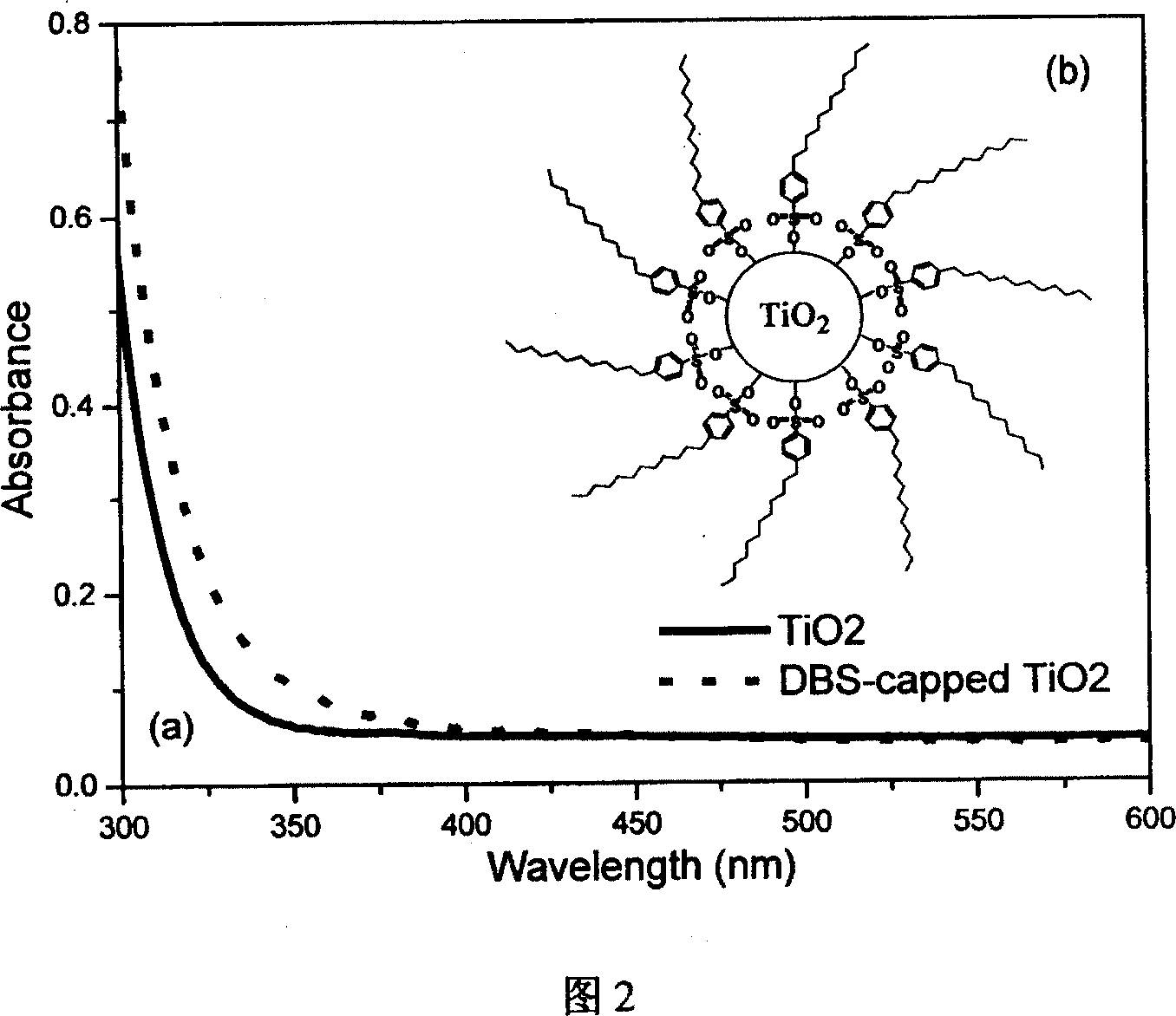

[0029] Embodiment 2: A titanium dioxide nanocrystalline film electrode is placed in 5 * 10 -4 mol / L N3 dye in ethanol solution for 12 hours to sensitize. Add dropwise 0.1 ml containing 0.1 mol / l I 2 , 0.1 mol / liter LiI, 0.5 mol / liter 4-tert-butylpyridine, 0.6 mol / liter 1-methyl-3-propylimidazolium salt, 1% (mass fraction) sodium dodecylbenzenesulfonate / Nano-TiO 2 Acetonitrile / propylene carbonate (volume ratio = 1:1) solution, and then a piece of platinum-coated ITO glass was placed on the dye-sensitized nano-titanium dioxide crystal film, and clamped with a clamp for measurement. at 100mW / cm 2 Under white light irradiation, the open circuit photovoltage of the electrode is 649mV, and the short circuit photocurrent is 16.2mA / cm 2 , fill factor 0.65, energy conversion efficiency 6.7%. The half-life is 260 hours.

Embodiment 3

[0030] Embodiment 3: A titanium dioxide nanocrystalline film electrode is placed in 5 * 10 -4 mol / L N3 dye in ethanol solution for 24 hours to sensitize. Add dropwise 0.1 ml containing 0.1 mol / l I 2 , 0.1 mol / liter LiI, 0.5 mol / liter 4-tert-butylpyridine, 0.6 mol / liter 1-methyl-3-propylimidazolium salt, 2% (mass fraction) sodium dodecylbenzenesulfonate / Nano-TiO 2 Acetonitrile / propylene carbonate (volume ratio = 1:1) solution, and then a piece of platinum-coated ITO glass was placed on the dye-sensitized nano-titanium dioxide crystal film, and clamped with a clamp for measurement. at 100mW / cm 2 Under white light irradiation, the open circuit photovoltage of the electrode is 641mV, and the short circuit photocurrent is 14.0mA / cm 2 , fill factor 0.70, energy conversion efficiency 6.3%. The half-life is 370 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com