Integrated device in low power dissipation for digital controlling magnetic bearing

A digital control, magnetic bearing technology, used in bearings, holding devices with magnetic attraction or thrust, shafts and bearings, etc., can solve the problems of reducing the anti-interference ability of the system, increasing the intermediate links of the circuit, etc., to meet the real-time requirements, Simplified circuit, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

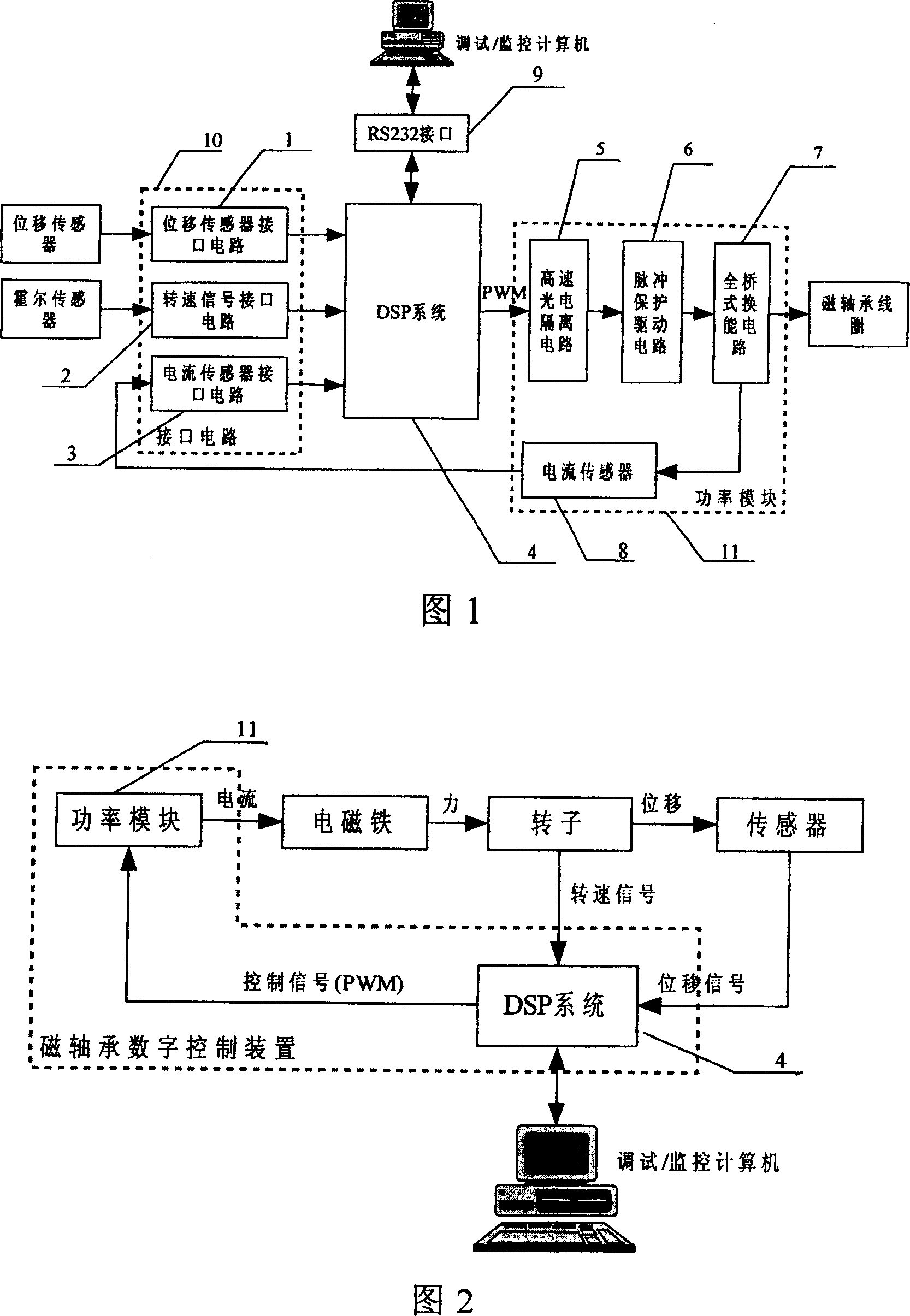

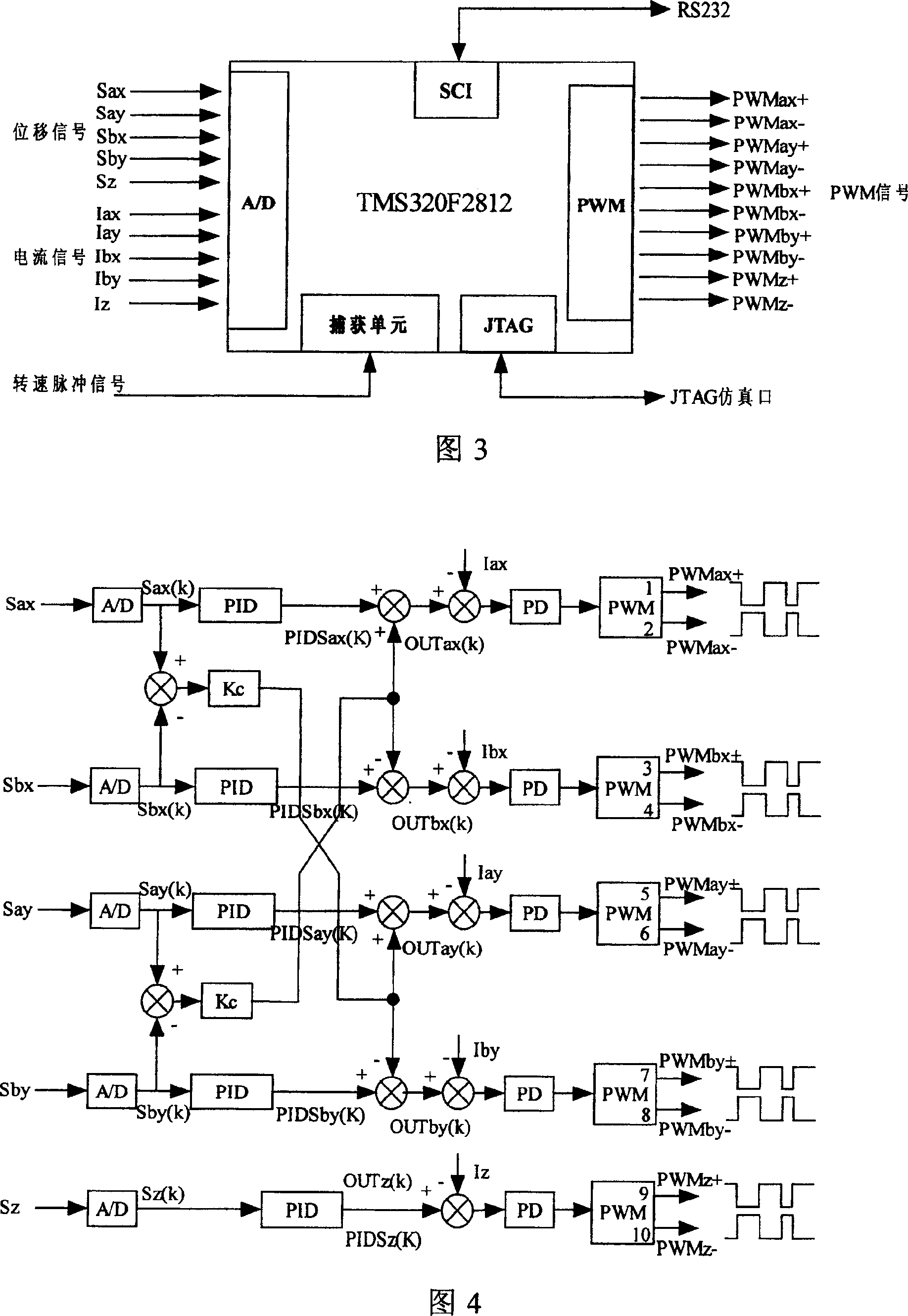

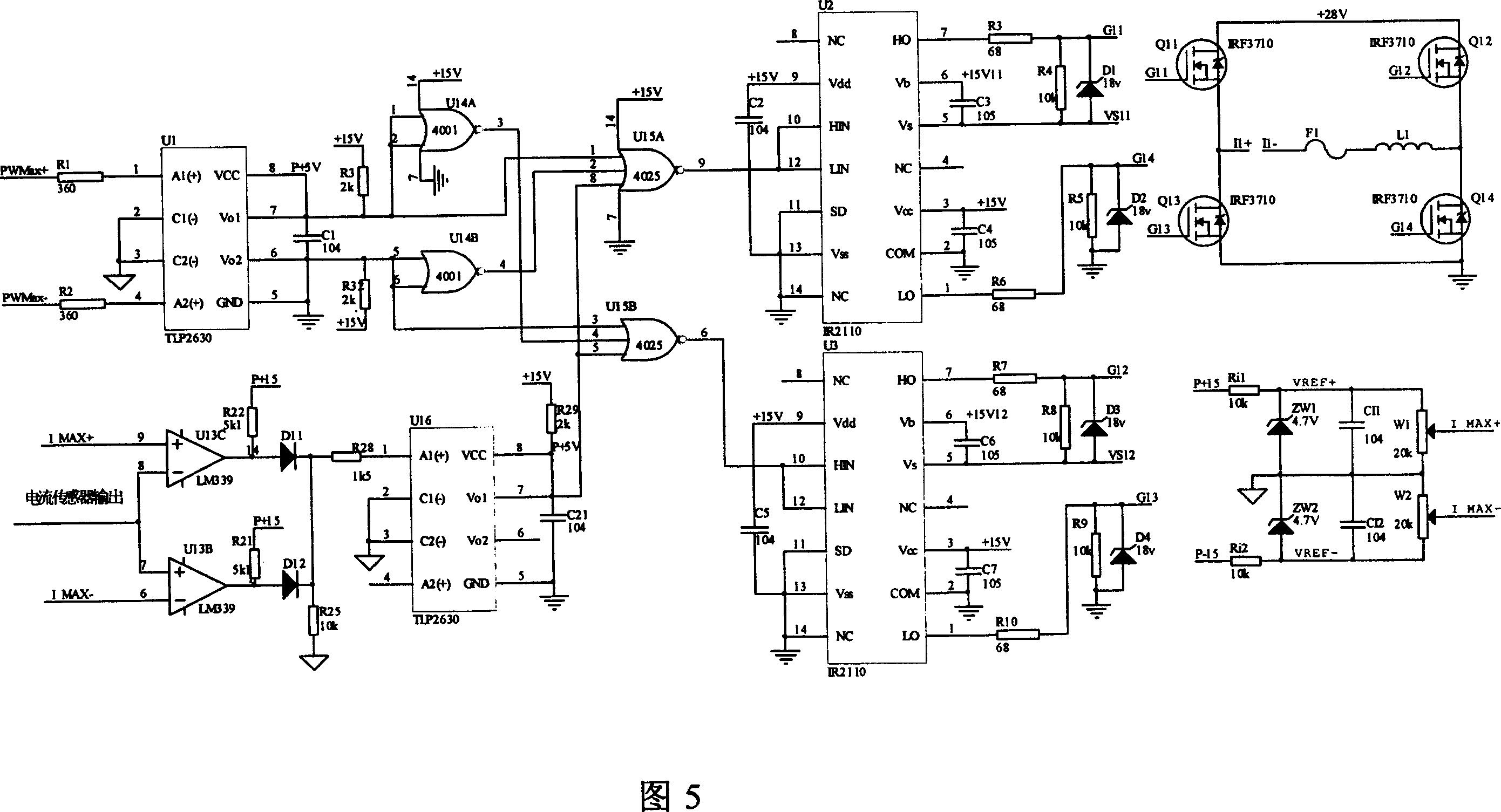

[0021] As shown in Figures 1 and 2, the present invention includes an interface circuit 10, a DSP system 4, and a power module 11, wherein the interface circuit 10 includes a displacement sensor interface circuit 1, a rotational speed signal interface circuit 2, and a current sensor interface circuit 3, and the power module 11 includes High-speed photoelectric isolation circuit 5, pulse protection drive circuit 6, full bridge transducer circuit 7, current sensor 8, magnetic bearing displacement sensor The displacement signal of 5 degrees of freedom output by the displacement sensor is connected to the DSP system through the displacement sensor interface circuit 1 4. The Hall sensor is connected to the DSP system 4 through the speed signal interface circuit 2, the current sensor 8 is connected to the DSP system 4 through the current sensor interface circuit 3, and the DSP system 4 respectively samples the displacement signals of 5 degrees of freedom output by the displacement sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com