Improved lithium mangnese oxide-based active material

An active material, lithium oxide technology, applied in thin material processing, electrochemical generators, alkaline battery electrodes, etc., can solve the problems of difficulty in obtaining capacity loss, large manganese oxide lithium-based electrode materials, low capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

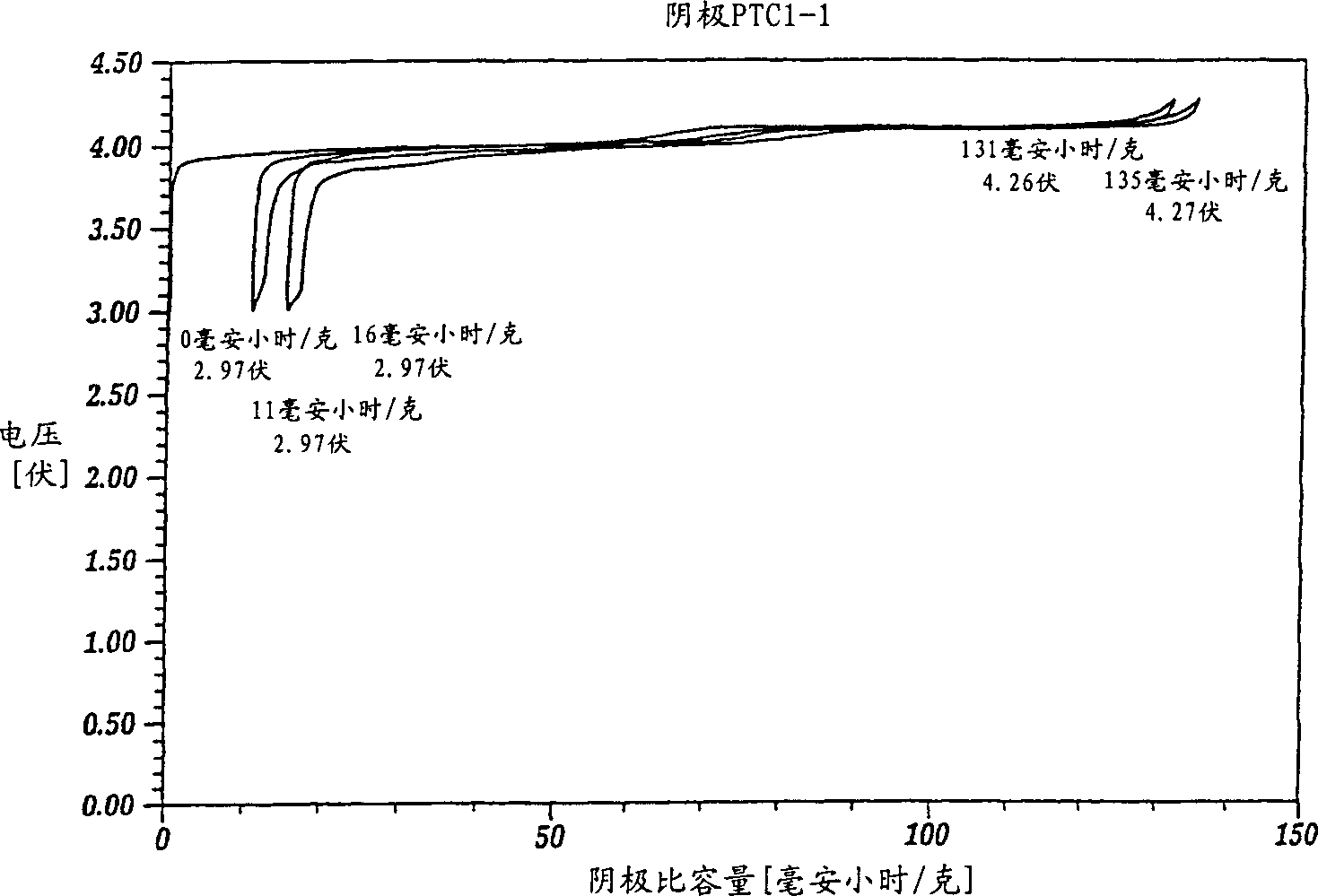

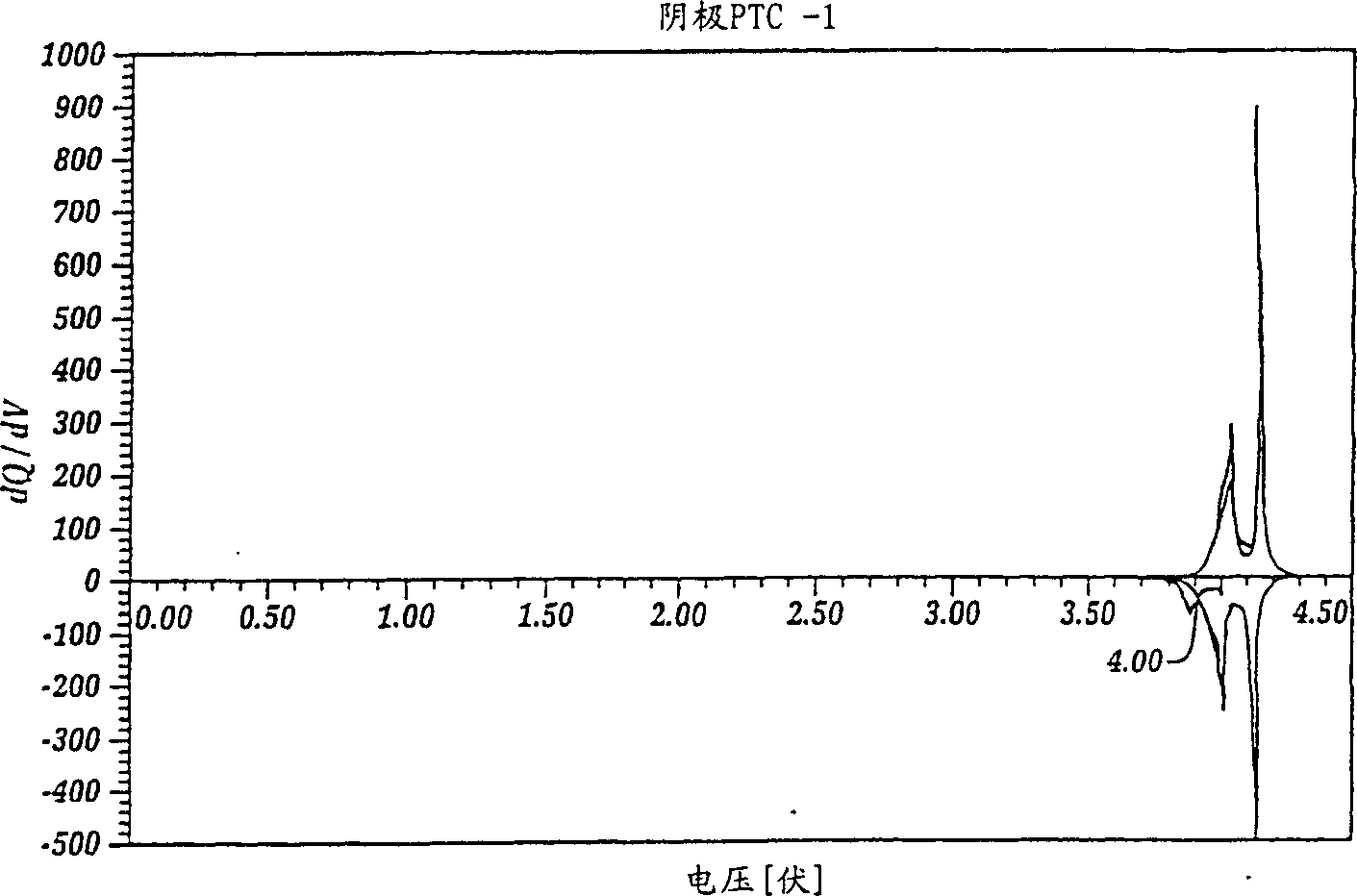

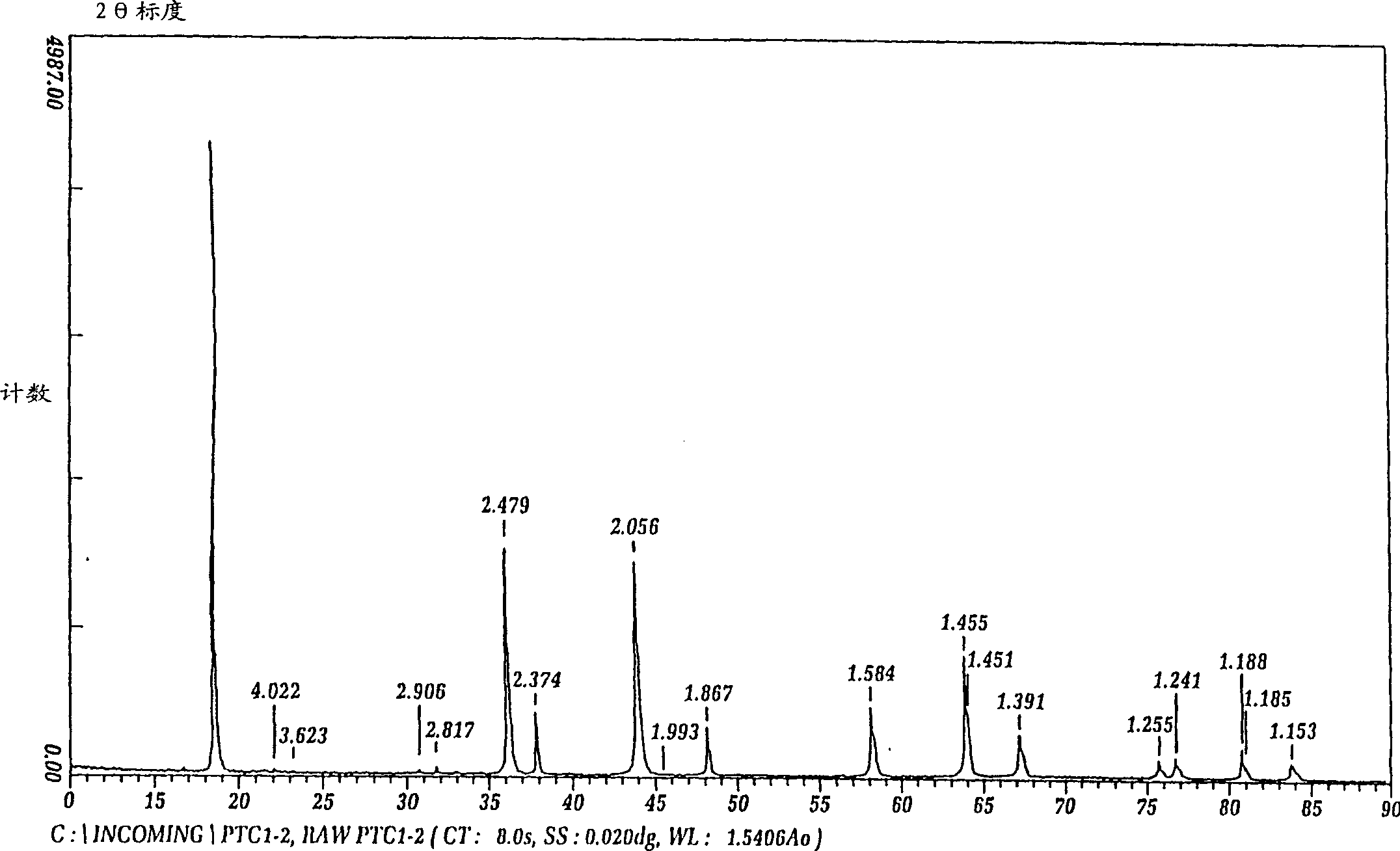

[0051] Embodiment 1: use the LMO: LiAlCl that is 96: 4 by weight ratio 4 to prepare

[0052] In this example, the treated lithium manganese oxide was prepared using a lithium aluminum chloride compound. The nominal molecular formula Li of lithium manganese oxide in the present embodiment 1.08 mn 1.92 o 4 , and purchased from Japan Energy Corporation. The molecular formula of lithium aluminum chloride is LiAlCl 4 . It was purchased from Aldrich Chemical Company. This lithium aluminum chloride is known to be hygroscopic. Therefore, the lithium aluminum chloride powder needs to be ground to the desired particle size under argon atmosphere. Finely ground lithium aluminum chloride and lithium manganese oxide powders were mixed and then milled together to obtain a well mixed mixture. The purpose of this is to get as homogeneous a mixture as possible. In this example, the mixture consisted of 4% by weight lithium aluminum tetrachloride and 96% by weight lithium manganese ox...

Embodiment 2

[0059] Example 2: 97:3 LMO:LiAlCl 4

[0060] According to the method described in Example 1, the difference is that the weight percentages of lithium manganese oxide and lithium aluminum chloride are changed. In this example, 3% by weight of lithium aluminum tetrachloride and 97% by weight of lithium manganese oxide were used. As shown in Table 2, this example provided a slightly higher amount of lithium, but essentially no change in cell parameters and peaks. In this example, the cycle performance was also good.

Embodiment 3

[0061] Example 3: 98:2 LMO:LiAlCl 4

[0062] According to the method described in Example 1, the difference is that 2% by weight of lithium aluminum tetrachloride is mixed with 98% lithium manganese oxide, and then heat treatment is carried out according to the method described in Example 1. As can be seen from Table 2, since a smaller amount of metal compound is used, the number of lithium atoms in the product is slightly increased compared with the above examples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com