Improved oxidation channel city sewage treamtent process

A treatment process and technology for urban sewage, applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc. High cost and other problems, to achieve the effect of low operating cost, reduced phosphorus concentration, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

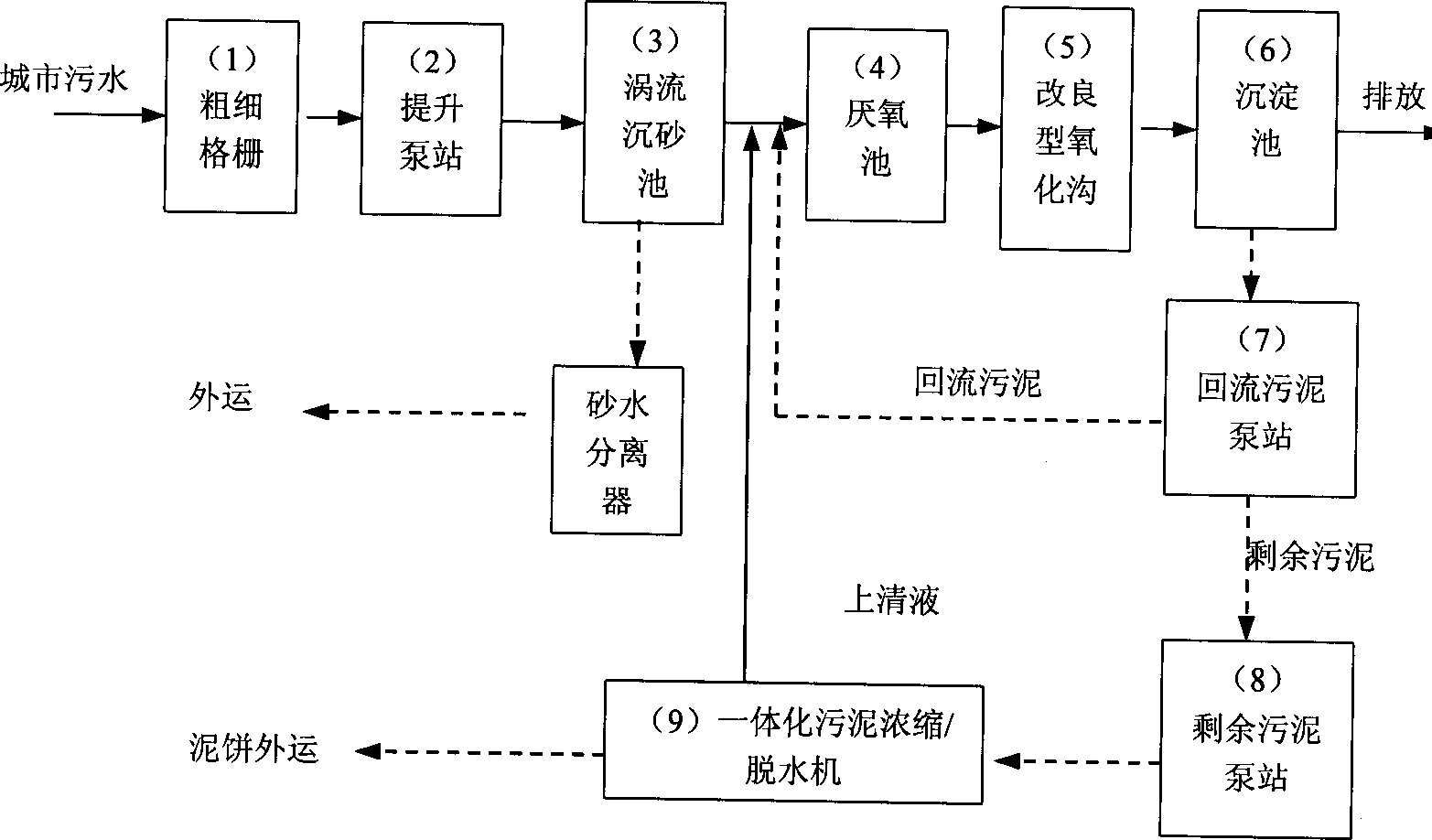

[0029] The specific embodiment of the present invention is further illustrated by accompanying drawing: see attached figure 1 : The process steps in the figure are:

[0030] (1) Coarse and fine grille

[0031] Coarse and fine screens are the first process in the improved oxidation ditch urban sewage treatment process. Its function is to salvage large and small pieces of floating objects in the water, such as plastic bags, branches, cardboard, etc., from the sewage, and prevent these floating objects from entering the subsequent lifting pump station and damaging the water pump.

[0032] (2), sewage lifting pump station

[0033] The sewage lifting pump station is the second process in the improved oxidation ditch urban sewage treatment process. Its function is to lift the sewage to the design height and provide the water head height for the artesian flow of water in the subsequent process.

[0034] (3), Vortex grit chamber

[0035] The vortex grit chamber is the third proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com