Field emitting cathode and its making process and application

A technology of field emission cathode and manufacturing method, which is applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve problems such as limiting technology application, and achieve strong field emission capability, high intensity, and low field strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

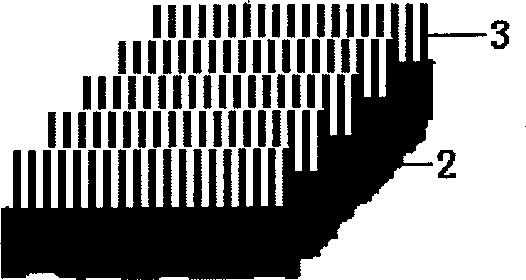

[0036] Such as figure 1 Shown is a schematic structural view of the field emission cathode of the present invention—a metal nanowire array. The nanopore templates used in fabrication have been dissolved away. Metal nanowires 3 of the same metal as the base metal film 2 are grown on the base metal film 2 , which is the base of the metal planar electrode, and the metal nanowires 3 are arranged in an array. Embodiment 2: Utilize the electrochemical deposition method to manufacture metal nanowire arrays

Embodiment 2

[0036] Such as figure 1 Shown is a schematic structural view of the field emission cathode of the present invention—a metal nanowire array. The nanopore templates used in fabrication have been dissolved away. Metal nanowires 3 of the same metal as the base metal film 2 are grown on the base metal film 2 , which is the base of the metal planar electrode, and the metal nanowires 3 are arranged in an array. Embodiment 2: Utilize the electrochemical deposition method to manufacture metal nanowire arrays

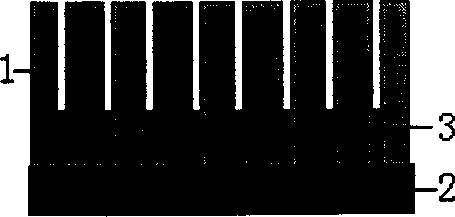

[0037] Such as figure 2 As shown, the selected metal is gold (Au), the selected nanopore template 1 is a polycarbonate template with a pore diameter of 30 nanometers (nm) and a thickness of 2 micrometers (μm), and the positions of the nanopores are randomly distributed. Vacuum deposit a 200 nanometer (nm) thick gold (Au) film on one side of the template, and then electroplate gold (Au) or copper (Cu) to a thickness of 10 microns (μm) to form a base metal film 2 as a field emi...

Embodiment 3

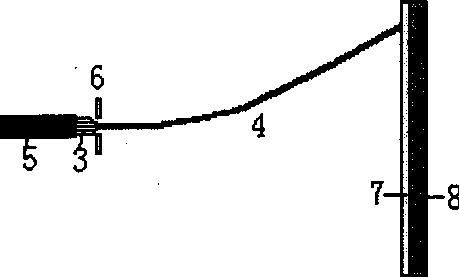

[0041] Such as image 3 Shown is a schematic diagram of the structure of the field emission cathode of the present invention—a metal nanowire array used as a cold cathode electron source for a cathode ray tube (CRT). The metal nanowire 3 is used as the electron source of the cathode 5 , and the electron beam 4 emitted by it is controlled by the grid 6 and emitted to the fluorescent screen 7 , which is placed in the glass envelope 8 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com