Three-dimension electrode reactor and use for treating organic waste water

A three-dimensional electrode and reactor technology, applied in the direction of electrochemical water/sewage treatment, water/sewage treatment, oxidized water/sewage treatment, etc., can solve problems such as rare research in the field of organic wastewater, and achieve improved biodegradability, To ensure the effect of emission standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

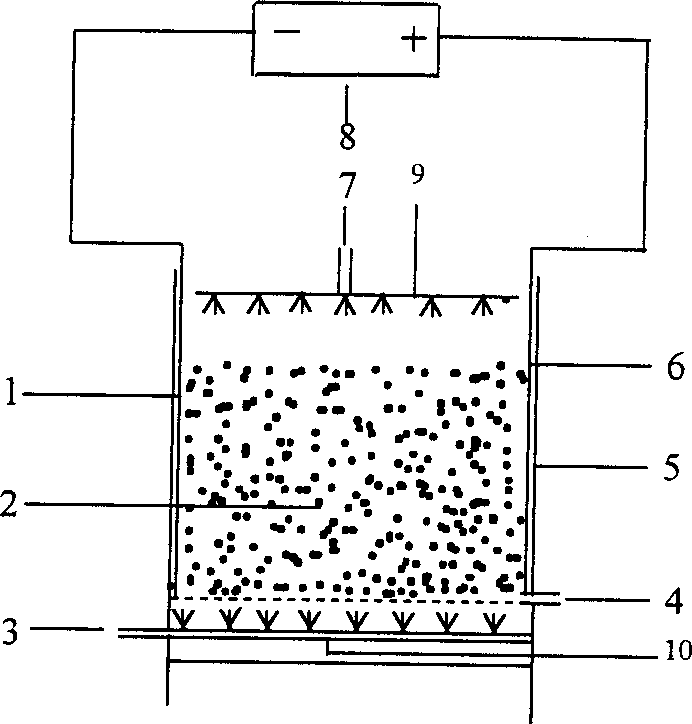

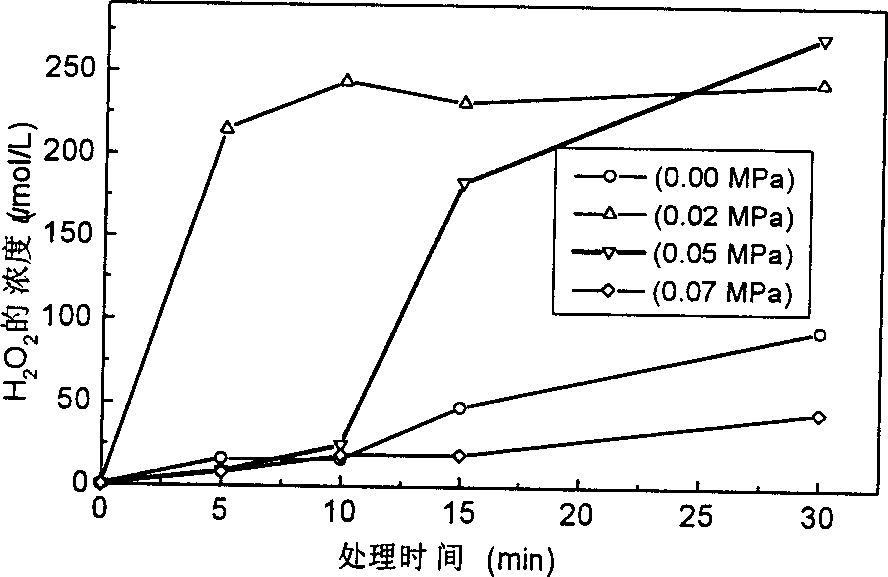

Method used

Image

Examples

example 1

[0026] Based on 91.0% iron filings (2-4mm particle size), 2% manganese dioxide, 0.01% platinum, 0.02% palladium, 0.5% copper oxide, 1.5% nickel oxide, 0.27% cobalt oxide and 0.7% oxide Zinc is used as an initiator, and a particle electrode with a particle size of 4-6mm made of 4% sodium carboxymethyl cellulose as a binder is used as a working electrode; a three-dimensional electrode is composed of graphite and polyester non-woven diaphragm as a feeding electrode reactor. at 0.3m 3 Under the air flow rate of / h, the phenol solution of 100 mg / l was treated for 60 minutes under the voltage of 20 volts, and the removal rate reached 92%. The removal rate of 500 mg / l chloral solution was treated for 30 minutes, and the removal rate reached 95%.

example 2

[0028] Based on 90% carbon, 2.0% manganese dioxide, 1.0% copper oxide, 1.25% nickel oxide, 0.22% cobalt oxide, 1.5% zinc oxide, 0.01% platinum and 0.02% palladium as initiator, 4% A particle electrode with a particle size of 4-6 mm made of sodium carboxymethyl cellulose as a binder is used as a working electrode; a three-dimensional electrode reactor is composed of graphite and polyester non-woven diaphragm as a feed electrode. at 0.16m 3 Under the air flow rate of / h, the 100mg / l NaCN solution was treated for 30 minutes at a voltage of 20 volts, and its CN - The removal rate reaches 97%. The removal rate reaches 95% when the chloral solution is treated for 30 minutes.

example 3

[0030]With 90% iron filings as the substrate, 3.0% manganese dioxide, 0.77% copper oxide, 2.1% nickel oxide, 0.3% cobalt oxide, 0.8% zinc oxide, 0.01% platinum and 0.02% palladium as the initiator, 3 % sodium carboxymethyl cellulose as the binder, the particle electrode with a particle size of 4-6mm is the working electrode; the three-dimensional electrode reactor is composed of graphite and polyester non-woven diaphragm as the feeding electrode. at 0.6m 3 Under the air flow rate of / h, the COD of a printing and dyeing factory in Taiwan under the voltage of 28 volts Cr Printing and dyeing wastewater with a concentration of up to 10608mg / l is treated for 15 minutes, COD Cr Concentration dropped to 3672mg / l, its COD Cr The removal rate is 65.3%, and the decolorization rate is 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com