Method for forming inorganic solid electrolyte film

A technology of electrolyte film and inorganic solid, which is applied in the field of forming inorganic solid electrolyte film, and can solve the problems of not showing ionic conductivity, undisclosed or suggested protective layer ionic conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

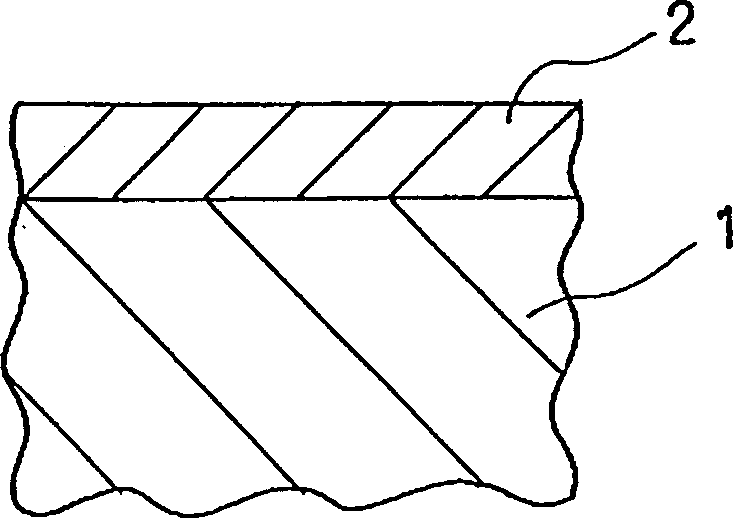

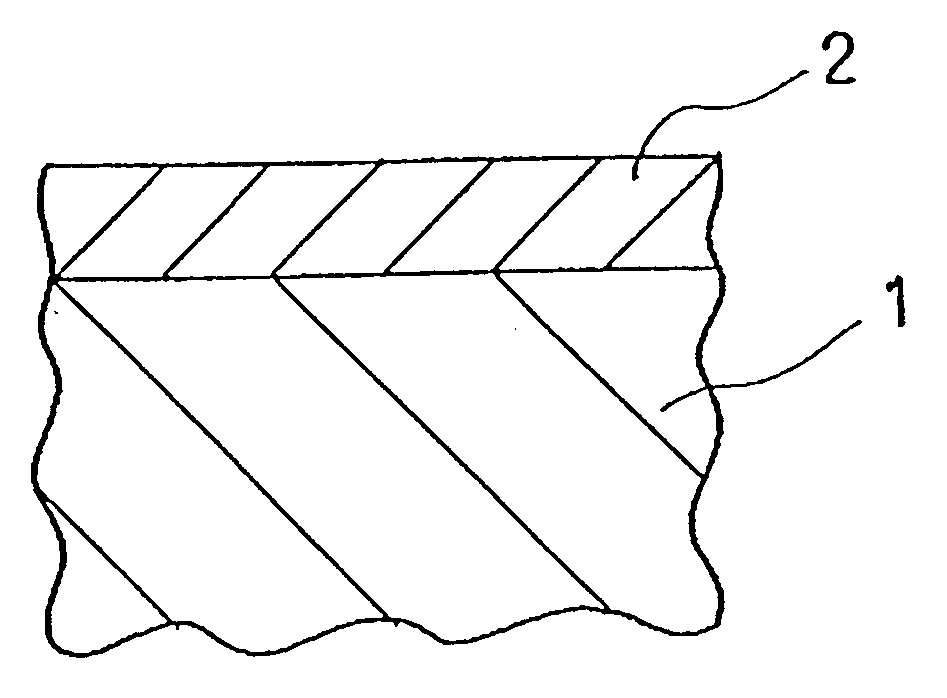

Image

Examples

Embodiment 1

[0038] On a quartz glass substrate, a 2 μm-thick inorganic solid electrolyte film was formed, and gold was vapor-deposited onto the film to form electrodes. The ionic conductivity of the resulting thin film was measured by this electrode. The evaluation of activation energy was performed with the following method, where the temperature dependence of ionic conductivity was determined from the measured temperature increase.

[0039] Tables 1 to 5 show the conditions and evaluation results of inorganic solid electrolyte thin film formation. Sample 0 was used for comparison, where the films were formed at room temperature without heat treatment. In the laser ablation method, the pressure is 2.66×10 -1 Pa(2×10 -3 Torr), the atmosphere was Ar gas, and a KrF excimer laser was used. During sputtering, the pressure is 1.33×10 1 Pa(1×10 -1 Torr) and an Ar gas atmosphere was used. In vacuum evaporation, the pressure is 1.33Pa (1×10 -2 Torr). In ion plating, the pressure is 6.65P...

Embodiment 2

[0048] A lithium metal thin film with a thickness of 10 μm was formed on a copper foil or leaf with a size of 100 mm×50 mm and a thickness of 10 μm by vacuum evaporation. On this lithium metal thin film, an inorganic solid electrolyte thin film having a thickness of 1 μm was formed. Alternatively, two sheets of lithium metal foils or leaves each having the same size as the copper foil or leaf and each having a thickness of 30 μm are bonded to each other. Inorganic solid electrolyte films can be formed on bonded lithium metal foils or leaves in a similar manner. Inorganic solid electrolyte films were formed under the same conditions as those of Samples 1-3, 5-7, 9-29 and 31-50, as shown in the above table.

[0049] Each base member having a lithium metal thin film and an inorganic solid electrolyte thin film formed thereon was used as a negative electrode to prepare a lithium secondary battery. Each negative electrode, a separator of a porous polymer film, a positive electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com