Micropollution water source treatment method

A treatment method and technology for water source water, applied in the directions of oxidized water/sewage treatment, adsorbed water/sewage treatment, etc., can solve problems such as high cost and increase gas solubility, and achieve the effects of increasing contact area, increasing solubility, and increasing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

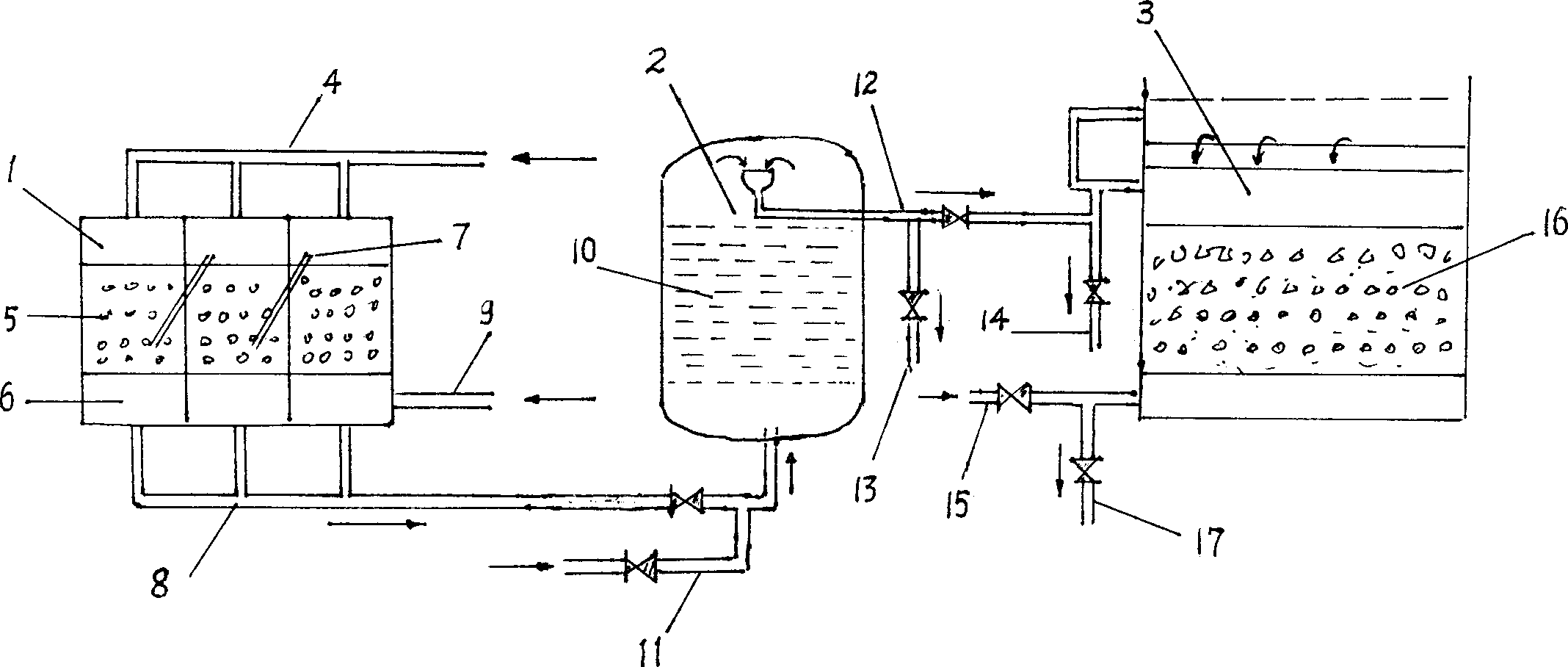

Embodiment 1

[0020] Embodiment 1 takes Changzhou canal source water as an example. Source water is composed of O 3 The water inlet pipe 4 of the dissolution tank enters, O 3 The height of the dissolution pool is 3.2 meters, the length is 3.0 meters, and the width is 2.5 meters. When the pressure is 0.06-0.12MPa, O 3 Oxygenated gas by O 3 The intake pipe 9 leads into, O 3 The dosage is 1.0-2.0Mg / L,, O 3 Contact with the source water for 10-15 minutes for oxidation, and then the source water comes out of the outlet pipe 8 and flows countercurrently into the zeolite filter tank 2. The height of the zeolite filter tank is 4.2 meters, the diameter is 3.0 meters, and the thickness of the filter layer of the zeolite filter tank is 1.0-2.0 meters, the filtration rate is 10-12 meters per hour, and the water flow out from the zeolite filter tank outlet pipe 12 finally enters the activated carbon filter tank 3 downstream. The activated carbon filter tank can adopt a reinforced concrete structure ...

Embodiment 2

[0021] Embodiment 2 takes the source water of Gehu Lake as an example. Source water is composed of O 3 The water inlet pipe 4 of the dissolution tank enters, O 3 The height of the dissolution pool is 3.5 meters and the width is 1.0 meters. When the pressure is 0.08-0.13MPa, O 3 The degassing gas is passed into through the intake pipe 9, O 3 The dosage is 1.5-3.0Mg / L, O 3 Oxidation time in contact with source water is 20-30 minutes, in O 3 Glass filler is added to the filler layer 5 of the dissolution tank to increase the O 3 The solubility of the gas in water, the thickness of the glass filler is 1.0-1.5 meters, from O 3 The water source water coming out of the gas dissolving tank outlet pipe 8 enters the activated carbon filter 3 downstream, the activated carbon filter can adopt a reinforced concrete structure, the height is 4.2 meters, the thickness of the filter layer of the GAC filter is 1.5-2.0 meters, and the filtration speed is 8- 10 m / h. The source water that co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap